The manufacturing sector today faces a dual challenge: on one hand, the opportunity offered by digital technologies to make processes more efficient; on the other, the growing risk of losing operational expertise gained in the field—especially in assembly processes, where direct experience of operators is often undocumented but essential.

To address this need, a modular technological platform has been developed that integrates:

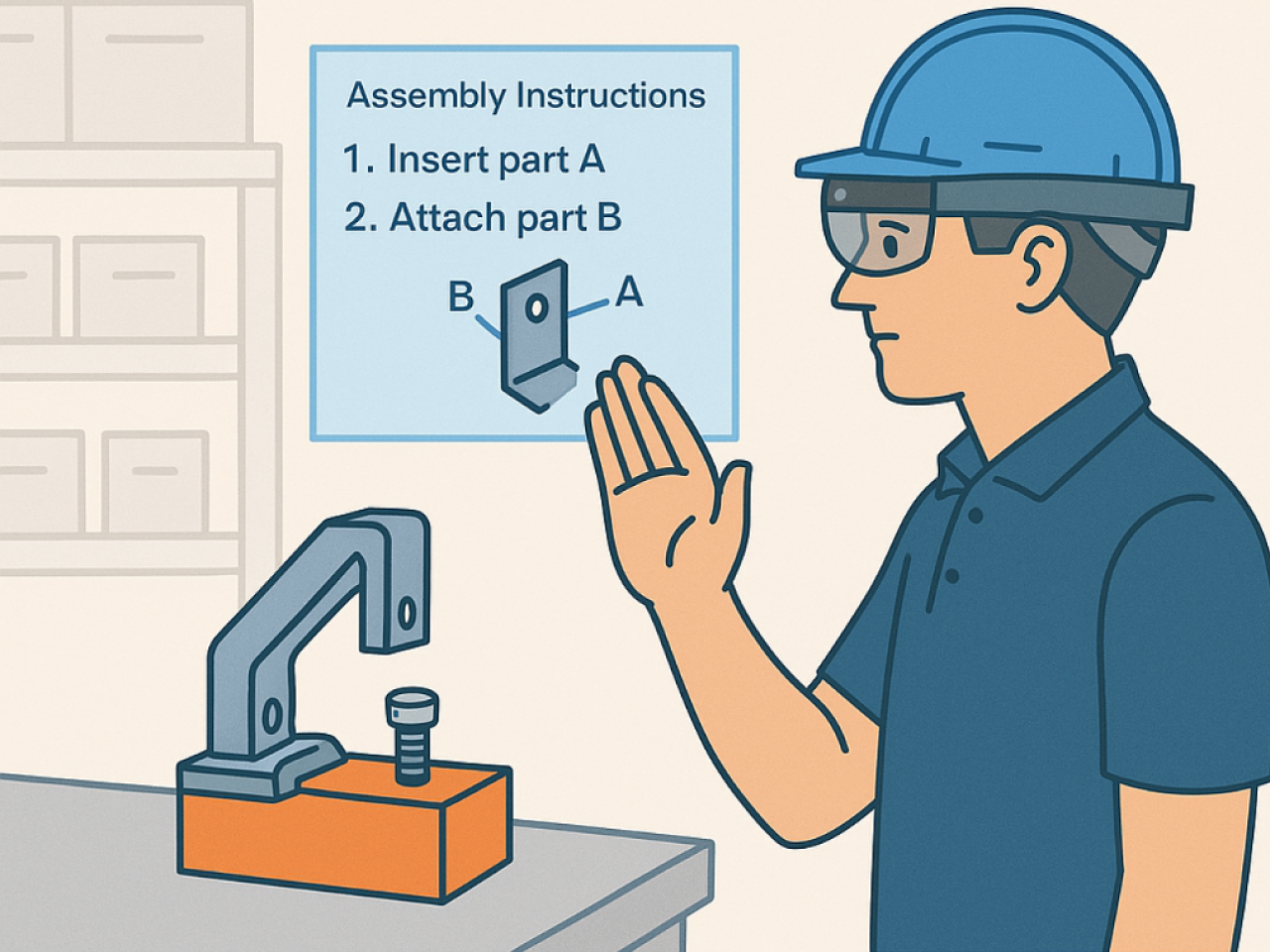

- advanced human-machine interfaces (HMI) based on augmented reality;

- data acquisition from machinery via edge architectures;

- formalization and sharing of operational know-how in a cloud environment.

The platform enables the acquisition, preservation, and transfer of implicit practical knowledge, supports on-site training, and improves the management of assembly processes, also from a circular economy perspective.

eXpert Knowledge formalization for a human-centered manufacturing

eXpert Knowledge formalization for a human-centered manufacturing

Based on a shared need among many manufacturing companies, particularly related to assembly, disassembly, and maintenance processes, the MUSP laboratory—together with other regional partners—has developed an innovative digital technology aimed at preserving and enhancing the know-how of expert operators, especially in the presence of personnel nearing retirement and difficulties in sourcing new skills.

This is achieved through an integrated edge/cloud system and advanced interfaces based on augmented reality (AR) devices, headsets, and displays that allow operators to receive contextual instructions and suggestions based on past experience, thereby improving the quality and efficiency of assembly operations.

This integration platform supports operators in selecting and managing components to be assembled, including recovered and compatible ones, promoting circular economy practices through the sharing of disassembled component availability for subsequent reuse.

This tool was developed within the KnowledgeX project.

KnowledgeX: a human-centered approach to know-how management in assembly introduces a modular platform that integrates edge computing, cloud, artificial intelligence, and augmented reality, offering a unique and human-centered approach to managing know-how in assembly processes.

The main innovation lies in the system’s ability to extract tacit knowledge from expert operators and process data, transforming it into ontologies and knowledge graphs. This knowledge becomes contextually and interactively accessible via AR headsets.

Compared to traditional solutions, KnowledgeX enables:

- Preservation and digitization of implicit know-how related to selection and assembly, including recovered components;

- Personalized and contextual training, with AR support guiding the operator in real time;

- Simplified operational decisions, for example in selecting compatible components or recycling;

- Strengthened production resilience, reducing integration times for new operators thanks to interactive instructions based on past experience.

The technology is applicable in manufacturing contexts with high variability in assembly, disassembly, and maintenance. It is useful in cases of shortage of qualified labor or generational turnover, facilitating the transfer of operational know-how. Through augmented reality devices and edge/cloud systems, operators receive contextual instructions that improve quality and efficiency, also promoting component reuse in a circular economy perspective.

Expert Knowledge Formalisation

Expert Knowledge Formalisation

Application in manufacturing with high variability in assembly, disassembly, and maintenance processes.

The technology is integrable into an industrial environment characterized by high variability in assembly processes and the presence of expert operators nearing retirement. Thanks to the use of AR devices and headsets, less experienced operators can access in real time a wealth of practical knowledge collected from senior colleagues, in the form of contextual suggestions and operational instructions. This database, built through observation, interviews, and on-site recordings, represents a fundamental resource for addressing non-standard situations, often absent in technical manuals. The main results obtained include:

- Reduced training time for new operators thanks to immersive, guided training based on real experience;

- Increased operational efficiency and reduced errors, especially in critical process steps;

- Decreased assembly defects observed in the period following the introduction of the technology;

- Integration of circular economy practices, thanks to optimized selection and reuse of recovered components.

Research partnership: MUSP Consortium (coordinator), ISTC-CNR, MISTER.

Industrial partnership: BLM, CAPELLINI, MCM.

Technology valorization activities are underway, including evaluation for patenting methodologies for acquiring, formalizing, and transmitting the implicit knowledge of expert operators. In parallel, collaborations with companies from different sectors are being explored to extend the use of the platform to diverse production contexts.

Semi-automatic and human-oriented approaches for knowledge extraction and representation in assembly operations

Semi-automatic and human-oriented approaches for knowledge extraction and representation in assembly operations