The design of control systems can be based on commercial off-the-shelf devices, easily scalable and interoperable. The rapid growth of the functionalities, which characterize modern control systems, complicates the selection of the proper architecture for automatic machines in terms of choice of centralized or distributed architecture, choice of the motion control, choice of the fieldbus, choice of the development environment etc. The goal of this activity is to assess the main PLC-based and PC-based technological solutions. At CIRI MAM laboratories and LIAM laboratory it is possible to develop testbeds for the main commercial control systems which are available in the industrial automation market.

Benchmarking laboratory

Benchmarking laboratory

The main innovative aspect of this application is the systematic approach to benchmark activities. Without a systematic approach that allows to understand pros and cons of the innovative solutions for the control it is possible to be dazzled by the suppliers' marketing and to lose the real value of these solutions. The benchmark activity is carried out starting from an analysis of the technology and a measure of the systems performance by means of experimental tests. In order to better evaluate current and future proposals coming from the suppliers, this application analyzes the control solutions via three phases: theoretical analysis of the solution; practical realization of the tests; evaluation of the results obtained.

A number of applications, in particular those in which the performance of the control system strongly influences the performance of the overall system and the choice of the control architecture is a crucial aspect, can take advantage by the proposed method.

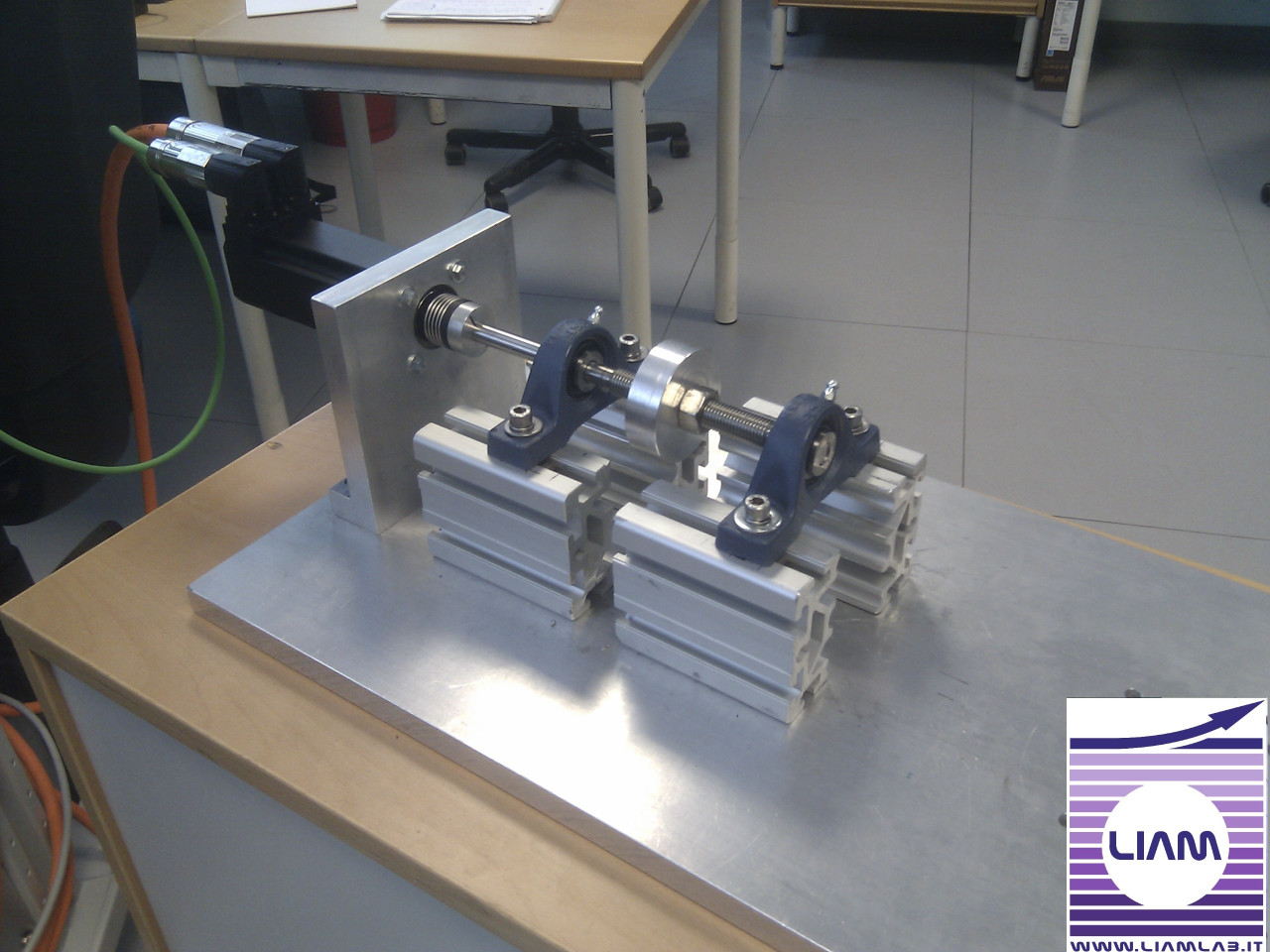

Benchmark testbed for distributed control

Benchmark testbed for distributed control

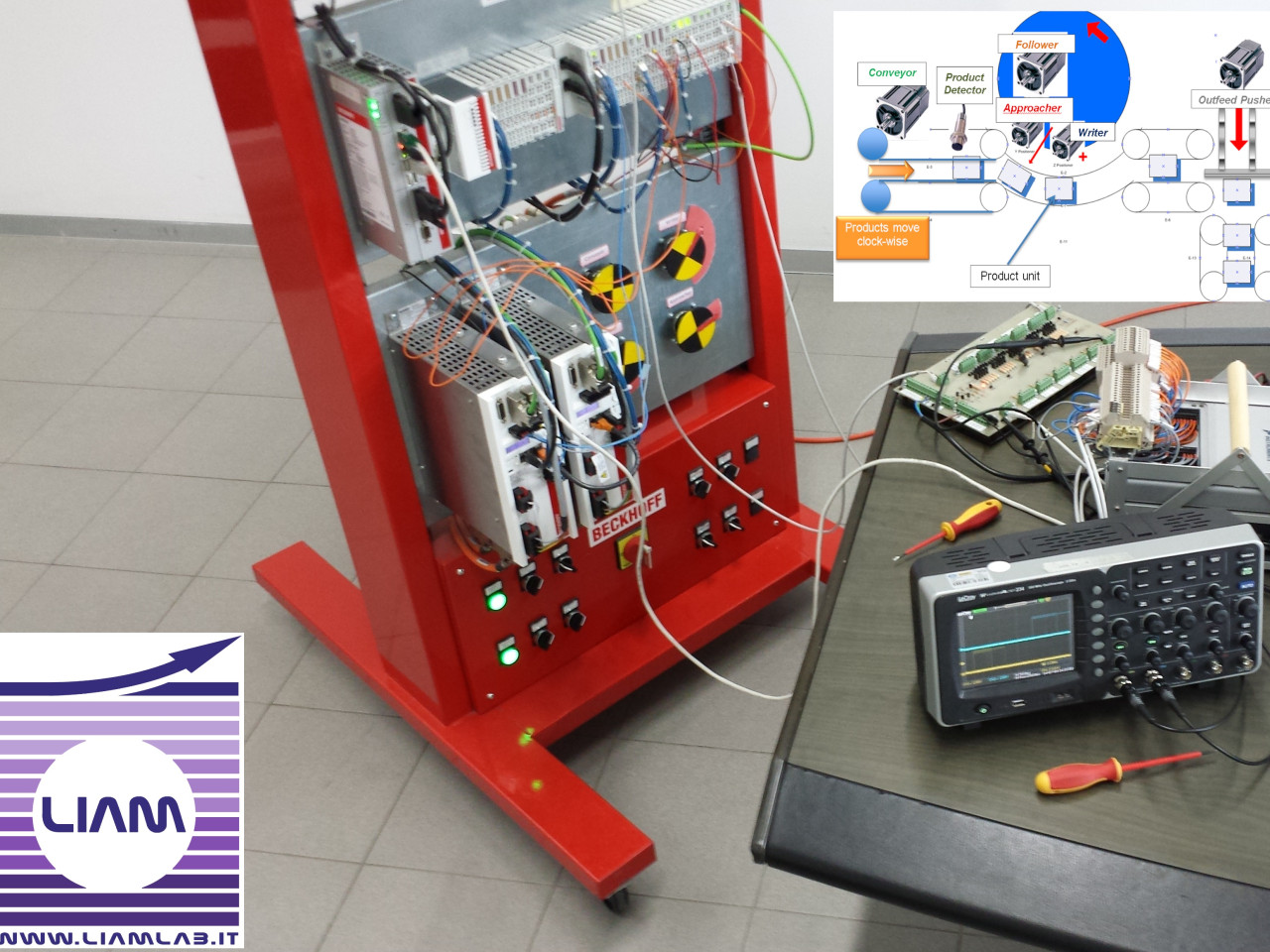

Evaluation of commercial platforms for the automation of automatic packaging machines.

This application is focused on the analysis of PLC-based and PC-based control solutions, by means of number of tests, which are carried out in three successive phases: tests on the devices (I/O, CPU) and fieldbus; tests on the motion control system; tests on the system integration. The last phase of the tests, aiming at evaluating the overall control architecture including both software and hardware aspects, has been performed by considering an application quite common in the field of packaging machines, i.e. a bonding machine. During this activity a number of solutions for distributed control (B&R, Beckhoff, Bosch Rexroth, Lenze, Mitsubishi, Omron, Rockwell, Schneider, Siemens) have been evaluated.

LIAM - Laboratorio Industriale Automazione Macchine per il packaging

The cooperation among CIRI for Advanced Mechanics and Machines, the Laboratory of Automation and Robotics and LIAM has led to excellent results and has induced LIAM to continue the benchmark activity.

Bonding machine chosen as benchmark

Bonding machine chosen as benchmark