The project develops an optimization model based on Mixed-Integer Linear Programming (MILP) to plan CCS (Carbon Capture and Storage) chains, essential for reducing emissions in Italy's hard-to-abate industrial sectors. The model minimizes implementation and operational costs for CO₂ capture, transport, and storage, considering variables such as capture technologies (post-combustion, oxy-combustion), transport modes (pipeline, train, truck, ship), and an offshore storage site in the Adriatic. Applied to 61 industrial plants (cement, steel, refineries, and WtE), it enables infrastructure planning to decarbonize up to 22 MtCO₂/year by 2050. The model provides a flexible, scalable tool for policymakers and investors, supporting strategic decisions and long-term economic assessments for efficient and sustainable CCS infrastructure

Carbon Capture and Storage chain (source: iStock)

Carbon Capture and Storage chain (source: iStock)

The project presents an optimization model based on Mixed-Integer Linear Programming (MILP) to design Carbon Capture and Storage (CCS) chains, a key technology for decarbonizing hard-to-abate industrial sectors. These sectors, including cement plants, steel mills, refineries, and Waste-to-Energy (WtE) plants, are characterized by high CO₂ emissions and limited alternative solutions for significant reductions.

The model is aimed at policymakers, investors, and industrial planners, providing strategic support for CCS infrastructure implementation. By minimizing the Total Annualized Costs (TAC), it encompasses all CCS chain stages: CO₂ capture at emission sites, multimodal transport (pipeline, trains, trucks, ships), and final offshore storage in the Adriatic Sea. Its functionality relies on detailed inputs, including site emissions, capture and transport technology costs and performance, and decarbonization targets.

This model serves as a flexible and scalable tool, enabling simulations across diverse scenarios and targets, up to 22 MtCO₂/year sequestered by 2050. It ensures an optimized approach balancing economic and environmental needs, facilitating strategic decisions for sustainable long-term CCS infrastructure.

The project introduces an innovative MILP optimization model that combines detailed geographic granularity with a modular approach for CCS chain planning. Compared to the state of the art, the model integrates sector-specific and technological variables (e.g., capture technologies tailored for cement, steel, and WtE) with multimodal transport options, enabling flexible and scalable planning.

A key innovation lies in the simultaneous optimization of capture, transport, and storage, balancing costs, performance, and environmental constraints over a 20-year horizon. By leveraging high-resolution inputs, such as localized emissions and specific CAPEX/OPEX costs, the model allows customized simulations, overcoming the rigidity of traditional continental-scale models.

Additionally, the application to the Italian context, with a focus on multimodal infrastructure and offshore storage, provides cost-effective strategies to accelerate the decarbonization of hard-to-abate sectors.

The model is applicable to hard-to-abate sectors such as cement, steel, refineries, and Waste-to-Energy (WtE), optimizing tailored CCS chains to reduce CO₂ emissions. It supports policymakers and investors in planning decarbonization infrastructures, contributing to climate targets. Also adaptable to diverse geographic and temporal contexts, the model enables strategic decisions for sustainable transitions in high-emission industrial sectors.

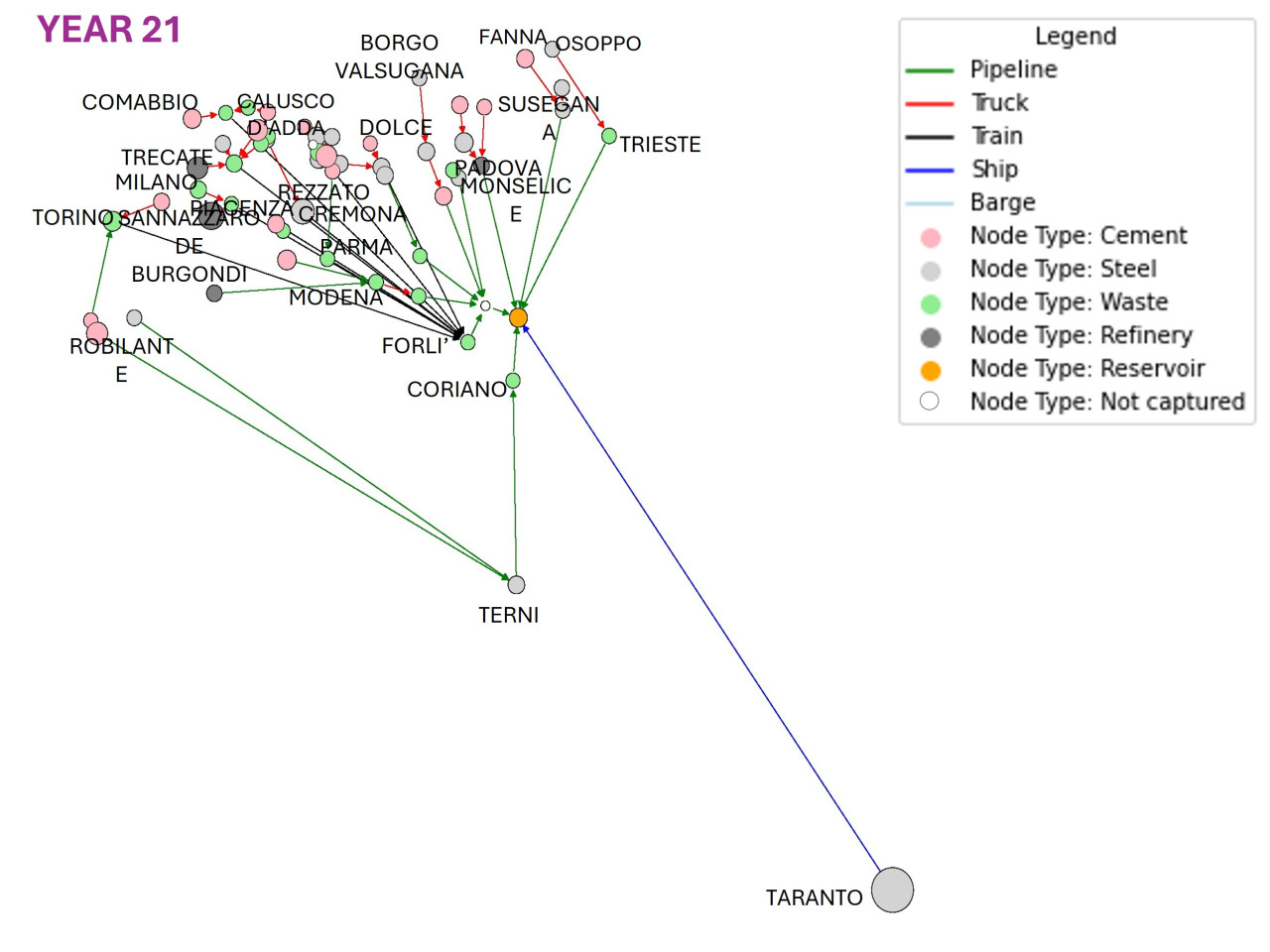

Infrastructure projects planned with the MILP model

Infrastructure projects planned with the MILP model

Application of the MILP Model for CCS Chain Planning in Italy's Hard-to-Abate Sectors: Capture, Transport, and Storage of up to 22 MtCO₂/year

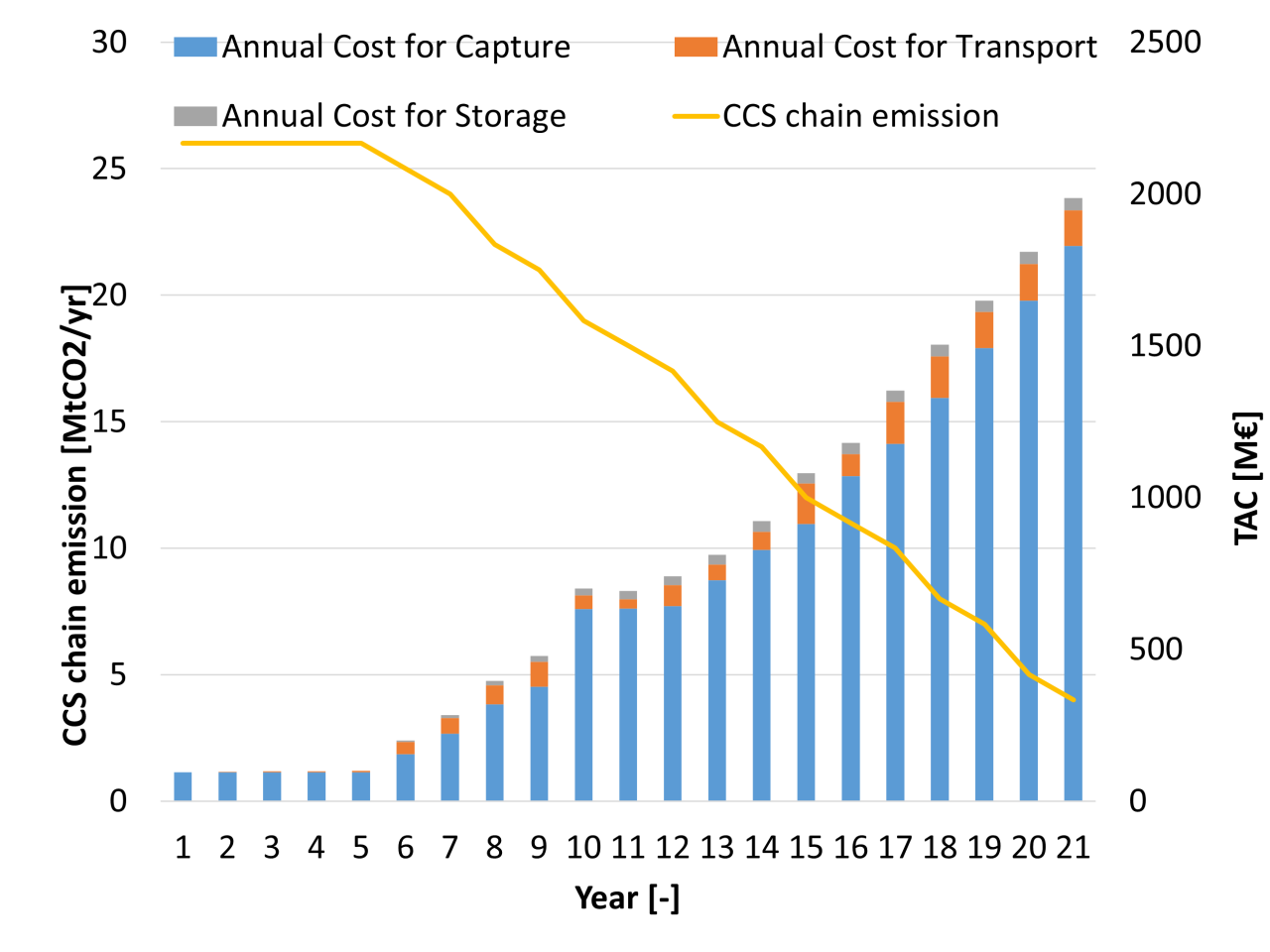

The MILP model was applied to CCS chain planning in Italy, analyzing 61 industrial plants across cement, steel, refineries, and WtE sectors. The goal was to optimize CO₂ capture, transport, and storage costs, balancing economic and environmental constraints over a 20-year horizon.

By year 21, the infrastructure captures 25 MtCO₂/year with approximately 2000 km of pipelines. The total annualized cost (TAC) is 6775 M€, with 89% tied to capture, 8% to transport, and 3% to storage. Pipelines are preferred for medium-long distances, while trucks and trains are optimal for short routes and distances over 150 km.

The model identified optimal strategies for progressive infrastructure deployment, starting with cement plants (cheapest), followed by WtE, steel mills, and refineries. The minimum Annualized Cost of Stored Carbon (ACSC) of 29.2 €/tCO₂ is achieved in year 18. The application demonstrated the feasibility of scalable, sustainable CCS infrastructure to support national climate targets.

LEAP, Politecnico di Milano

The model can be valorized through collaborations with companies in hard-to-abate sectors to customize and apply the tool to their specific needs. Partnerships with industrial operators and public institutions are planned to implement CCS infrastructure at regional and national scales, with potential for creating spin-offs focused on consultancy and technological development.

Breakdown of annual costs for capture, transport and storage (primary axis) versus CCS emission chain (secondary axis)

Breakdown of annual costs for capture, transport and storage (primary axis) versus CCS emission chain (secondary axis)