Liquefied Natural Gas (LNG) is a low environmental impact fuel capable of reducing considerably the emissions of sulfur oxides and nitrogen oxides, as required by the European regulation (directive 2012/33 / EU). The CLEANPORT project provided the development of a small-scale LNG supply system for naval propulsion, together with the design of a LNG production, compression, liquefaction and storage system for naval use in port areas and very short routes (entry and exit manoeuvring operations). The project provides the integration with a smart-grid on the ground through biogas networks, where the natural gas is purified for combustion in marine diesel engines (already modified and adapted to dual/mono-fuel supply). The smart-grid on the ground compresses and liquefies the gas for the subsequent transfer/storage on board of the naval units.

Prototype for the LNG conversion of small-scale naval unit with Diesel engines

Prototype for the LNG conversion of small-scale naval unit with Diesel engines

The use of liquefied natural gas (LNG) as marine fuel is one of the most promising technologies for the drastic reduction of air emissions in densely populated areas, such as ports and neighboring cities: up to date there are no implementations of such technology on small/micro scale naval units that can be validated and operative.

The potential applications are different: - Integration on the ground with energy-based smart grids - Use of renewable sources through the integration with natural gas from biomasses - Accumulation and storage of LNG for external users

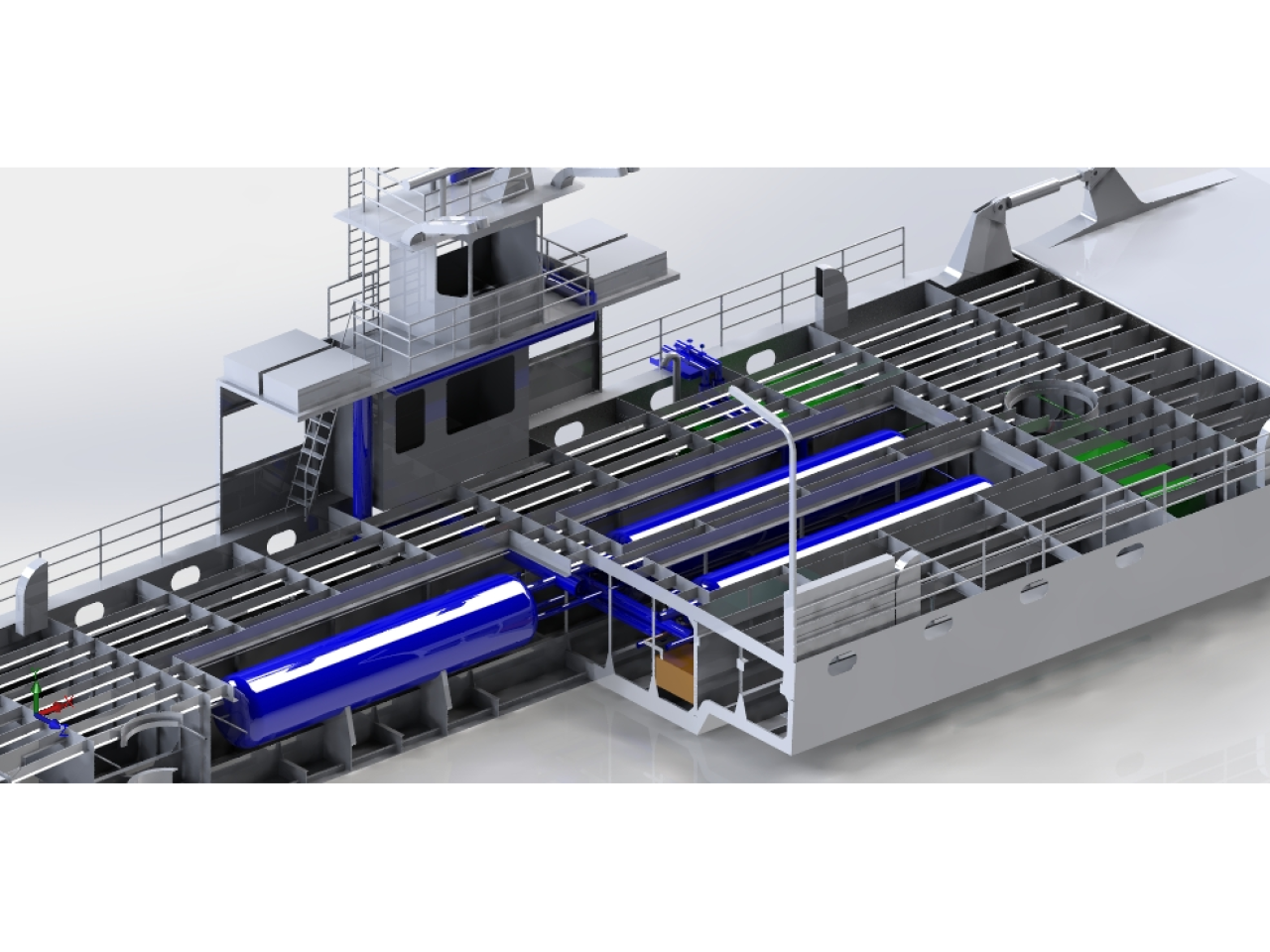

LNG supply system for small-scale naval unit

LNG supply system for small-scale naval unit

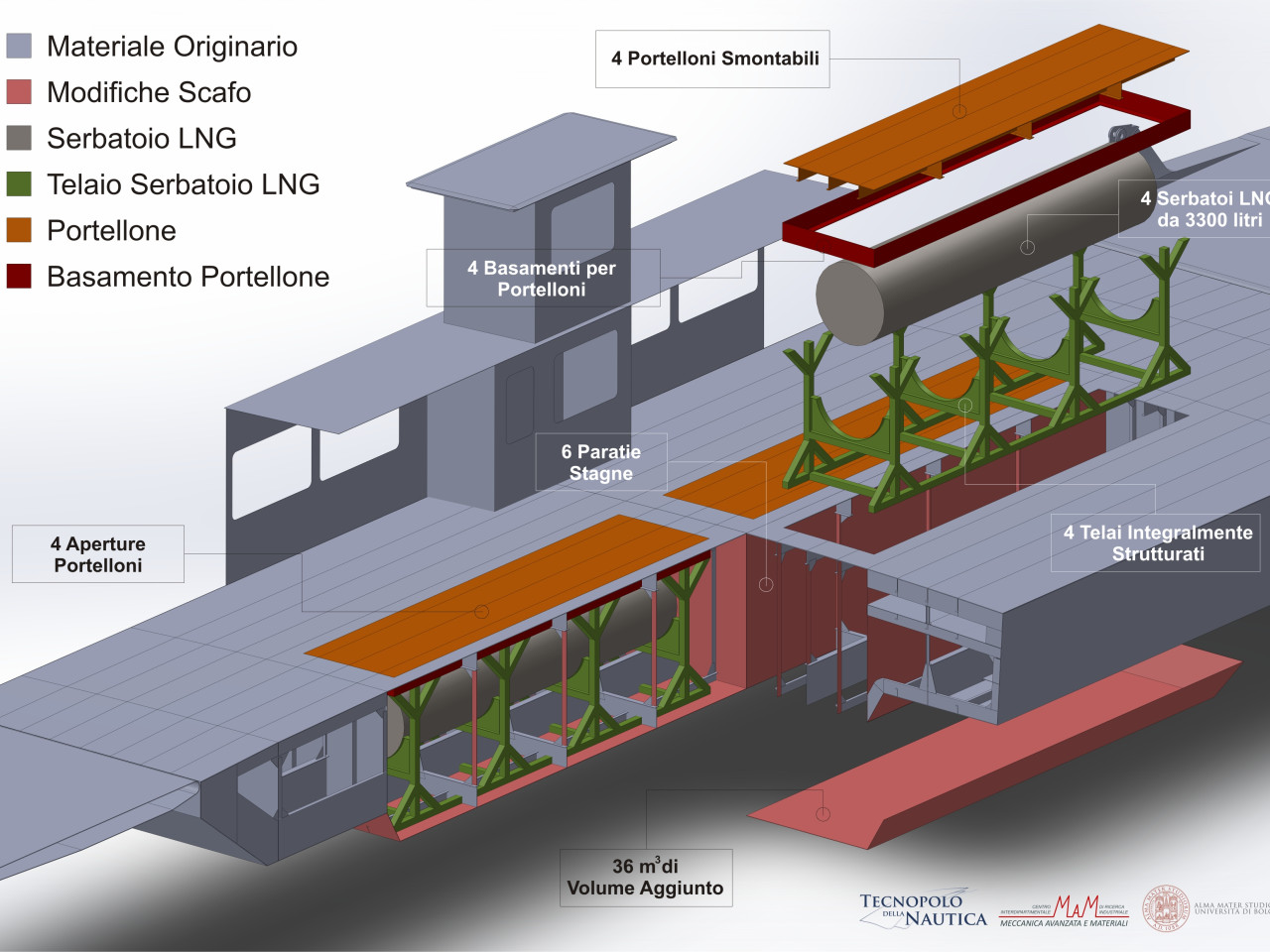

LNG conversion of the ro/pax BALENO RA-3770

In cooperation with companies specialized in the shipbuilding sector, the CLEANPORT project provided a technical/economic feasibility study for the LNG technology conversion of the maritime transport unit BALENO RA-3770, actually operating at Porto Corsini/Marina di Ravenna. For the 4 cryogenic tanks inside the ro/pax ferry hull, a structural modification was necessary in order to guarantee a safety level no less than the required by applicable Standards (IGF Code). A structural layout has been designed for the LNG tanks stocking below deck, while containing the impact on the existing structure of the ferry. The main changes have been: a local lowering of 500 mm of the bottom close to the housing of the four tanks and an increase of the cross-section area of the transverse reinforcements; the removal of the deck in the area where the four tanks are to be inserted; the removal of the props line to 1060 mm on the right and left of the hull; finally, in order to allow access to the tanks without affecting the operativity of the ro/pax ferry, four hatches have been created on the deck, each with dimensions such as to allow the extraction/replacement of the corresponding tank.

University di Bologna - CIRI MAM Tecnopolo della Nautica (RA) CIFLA - Centro Innovazione Fondazione Flaminia

Structural simulations were carried out with positive results to highlight feasibility problems. Structural stresses are compensated by the new geometry of the ro/pax ferry. The LNG conversion brings the BALENO-RA3770 to a level of buoyancy that guarantees the operativity of the ro/pax ferry, achieving severe reductions of the emissions compared to previous diesel-fuel engine system.

Ro/pax ferry BALENO - RA 3770 currently operating at Porto Corsini/Marina di Ravenna

Ro/pax ferry BALENO - RA 3770 currently operating at Porto Corsini/Marina di Ravenna