The researches activity has led to the development of a type of infill masonry blocks with high thermal-hygrometric performance, differentiated for thickness, internal layout and admixture, in order to ensure different performances as needed. Blocks are characterized by a specific mixture with expanded perlite, variable MPS and layout (morphology, size and holes distribution), such that allows an optimization of total performance. They appear as traditional infill masonry solutions and as facing bricks for residential civil constructions, but they are also applicable in industrial or commercial constructions, thanks to easiness to assembly, workability, high thermal- hygrometric and fire resistance performance. Blocks are made by vibro-compression and are characterised by an external layout suitable for lateral interlocking and surface grinded, in order to ensure the optimization of masonrys thermal performance reducing the thermal bridges due to mortar layer.

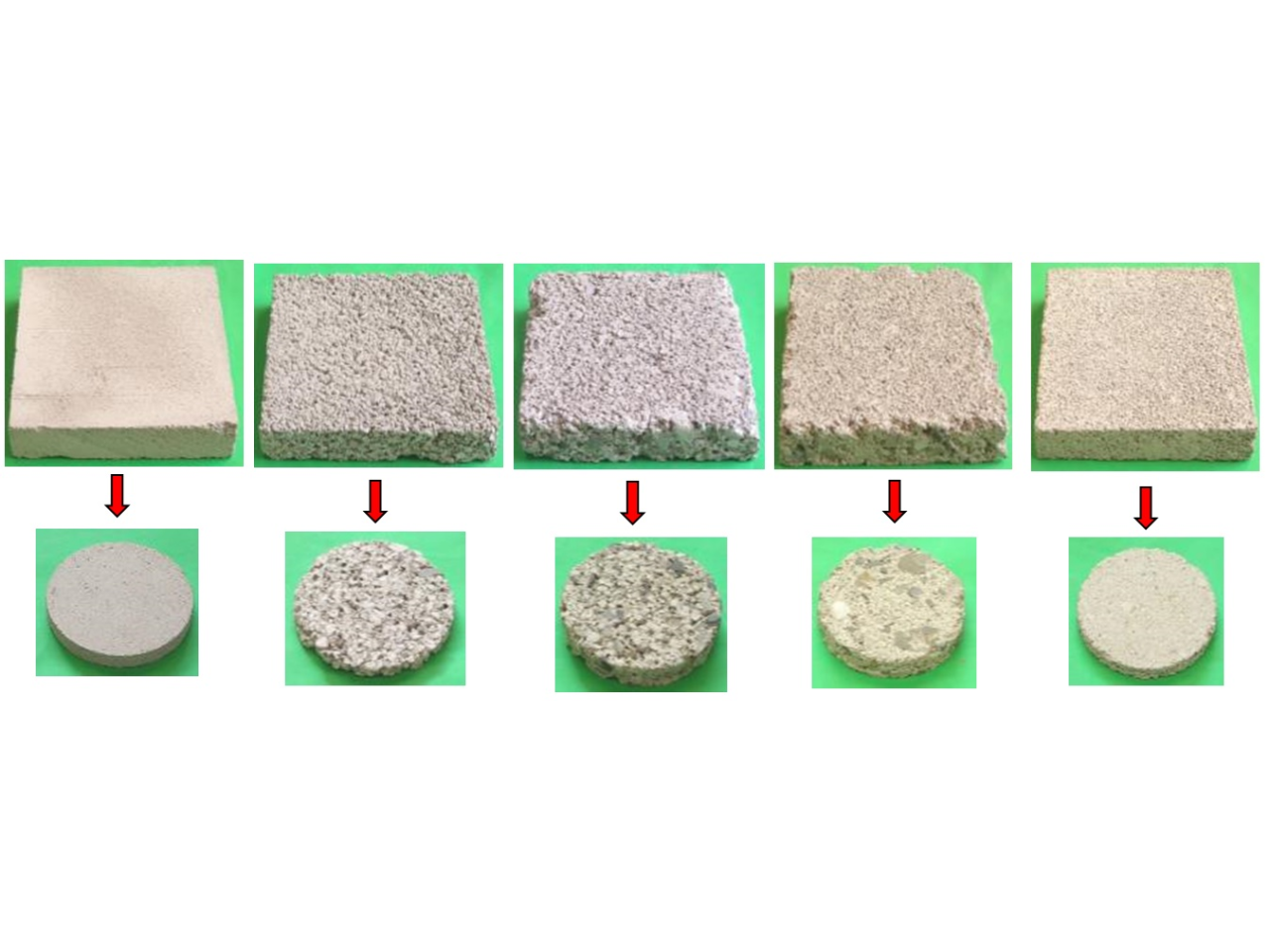

Experimental mixtures and specimens for measure the insulation degree of realized mixture.

Experimental mixtures and specimens for measure the insulation degree of realized mixture.

The addition in the mixture of until 50% of secondary raw materials allows costs reduction as well as important environmental benefits. The optimization of shape considers a remodelling of blocks external layout and of internal holes morphology. The external interlocking allows the installation without vertical mortar joints, while grinding allows installation with cementitious glue. The integrated design has allowed to optimize products performances, considering both normative and industrial production limits and has allowed to optimize workability, easiness to transport and installation.

Products are used for masonry with high thermal hygrometric performance. Different thicknesses allow the applicability to many kinds of building. The high level of thermal insulation degree pursued, with thermal transmittance up to 0.25 W/m2 K with thicknesses of about 38 cm plasters not included - doesn't penalize the wall's breathability, which remains very high, with the addition of increased indoor comfort. Finally, the optimization of thermal mechanical characteristics of heavier mixtures allows to use the product also in seismic zones.

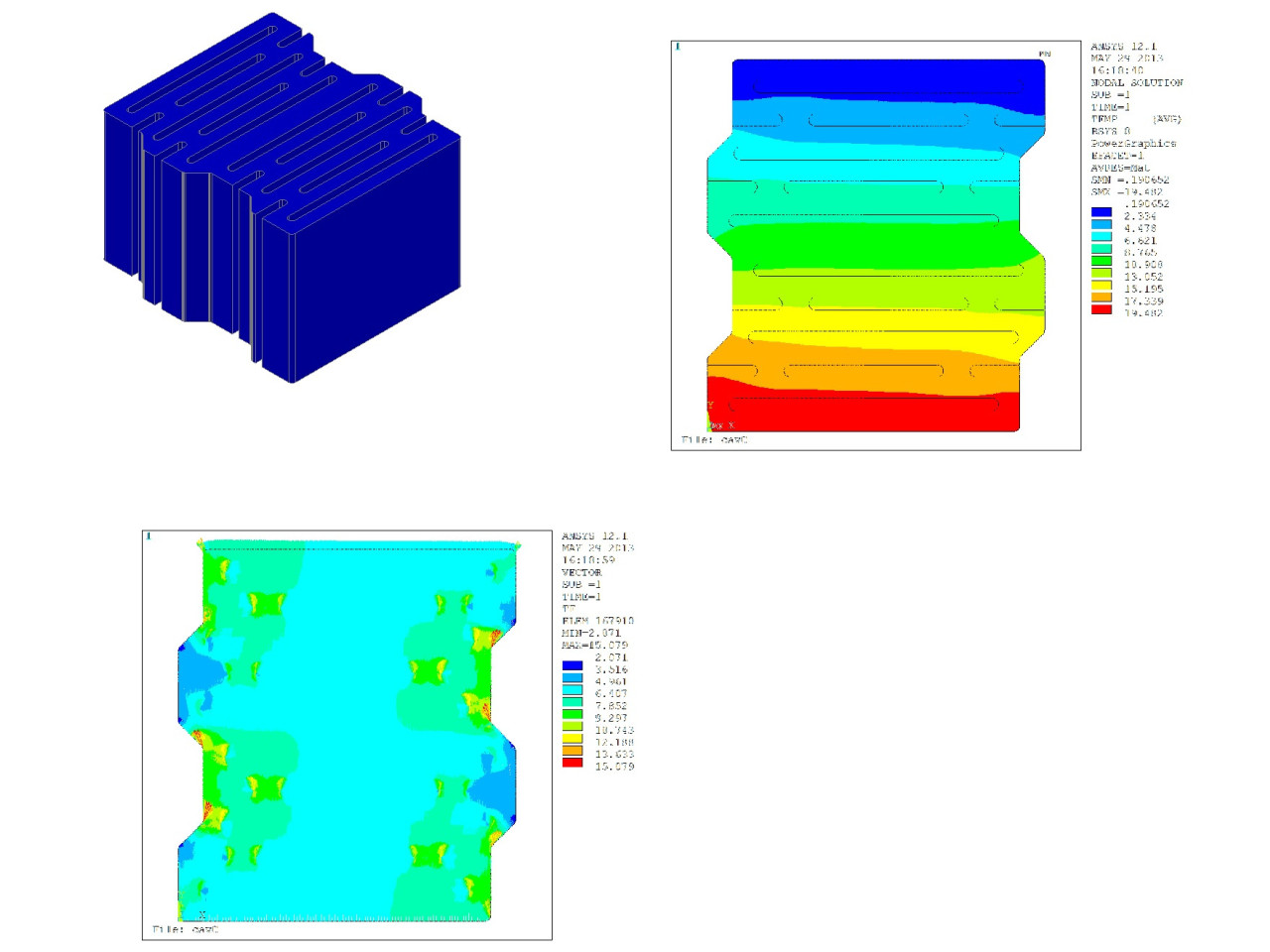

Developed shape and results of FE simulation (Finite Element) realized on the single block.

Developed shape and results of FE simulation (Finite Element) realized on the single block.

Realization of n° 6 blocks of flats Class A

The project is part of a wider urban renovation of a whole district and it involves the construction of a 4-storey building with loft, characterized by balconies with glass railings alternated to lodges, cornices above windows, decorative elements and shaped gutters. There are also large terraces and rib vault roof, which complete the construction with lightness and elegance. The project involves a place destined to tertiary activity that it's about 900 mq, while the residential area is about 7400 mq. In front of the building is involved the construction of a public square, which is needed to connect the existing part with the new, improved by commercial activities. The green and eco-save project was studied with the aim of reach Class A

M.V.B. S.r.l., Bregnano - Como Perlite Italiana S.r.l., Corsico - Milano

The innovative product developed by joint venture between the two company MVB and Perlite Italiana was patented with the name "PERLITECH TERMICO"

Construction of n°6 blocks of flats Class A in Albate, Como

Construction of n°6 blocks of flats Class A in Albate, Como