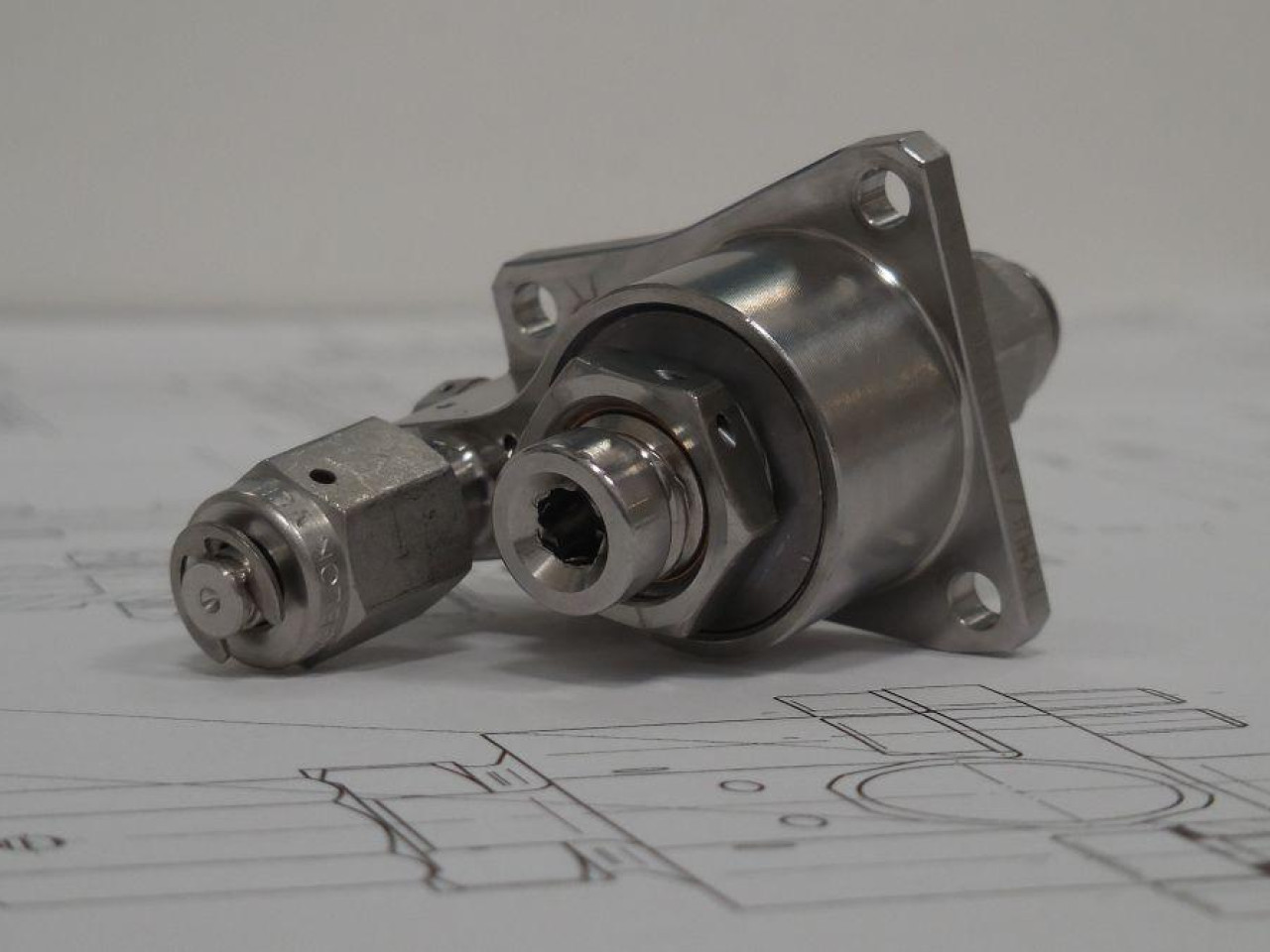

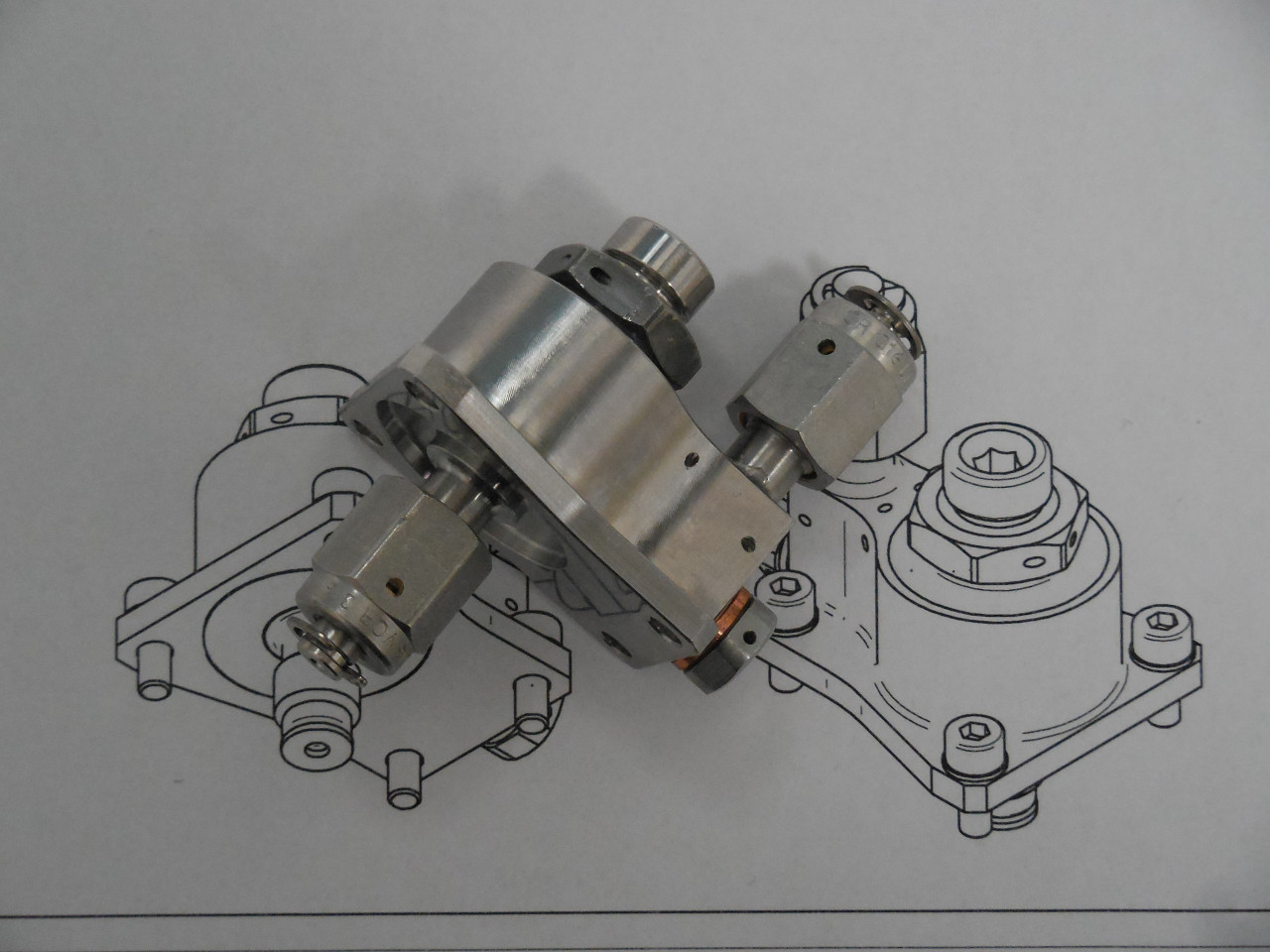

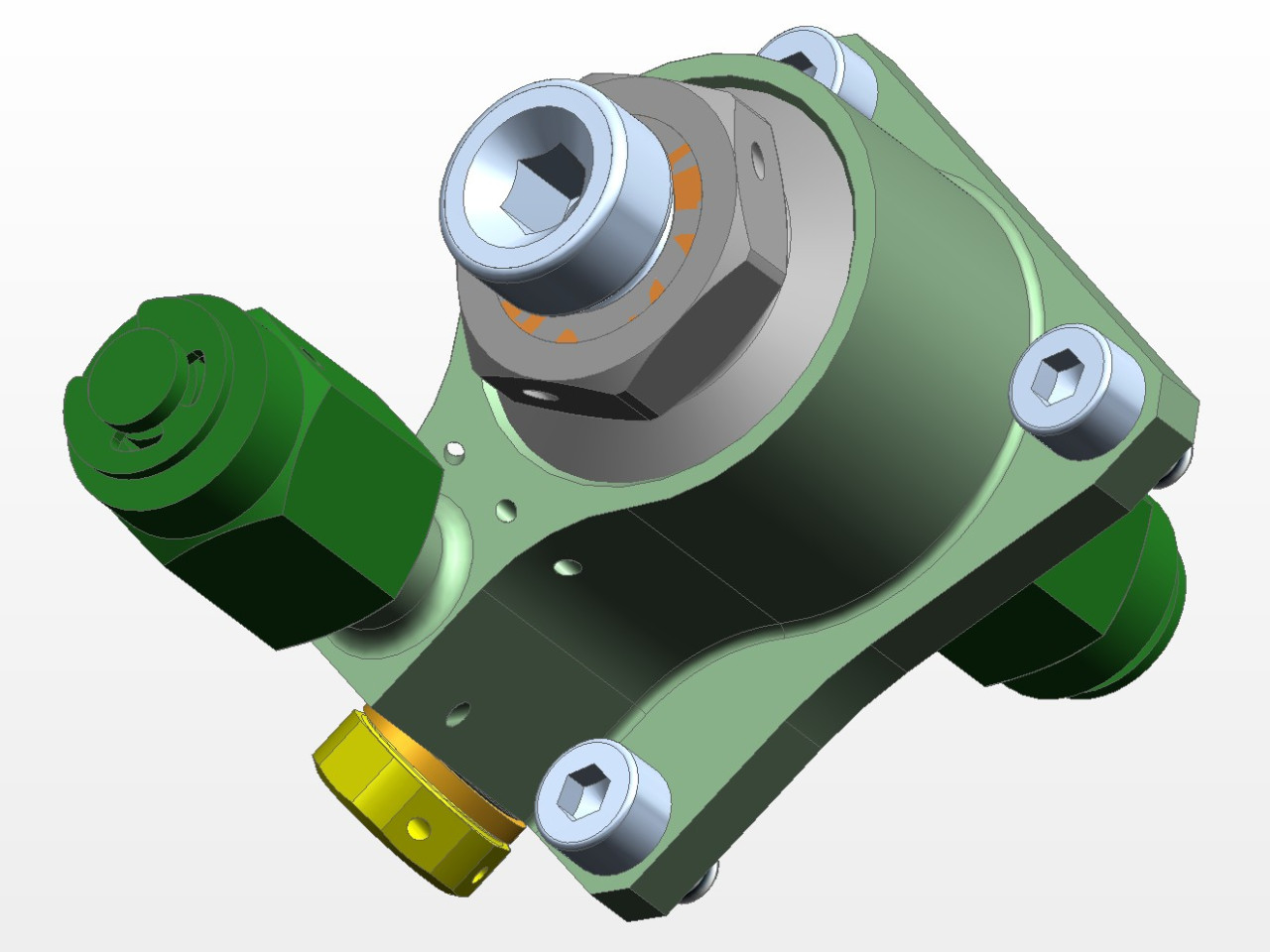

DTM has developed a filling valve to allow gas, liquid or fuel filling for extra high purity and high pressure applications. Main characteristics are high robustness environemntal conditions and reliability together with very low leak-rates and absence of molecular contamination.

Filling valve for Ultra Clean Zone of UCZ Exomars 2022 analytical laboratory drawer

Filling valve for Ultra Clean Zone of UCZ Exomars 2022 analytical laboratory drawer

Miniutirized components, no contaminating materials. High resisance to extreme temperatures. Low leak-rate.

Propulsion tanks, gas tanks requiring extra high purity, experimental systems

Filling valve for Ultra Clean Zone of UCZ Exomars 2022 analytical laboratory drawer

Filling valve for Ultra Clean Zone of UCZ Exomars 2022 analytical laboratory drawer

Filling valves for propulsion systems or ultra high purity systems

The filling valve developed by has been implemented as filling valve for Ultra Clean Zone of the Analyticial Laboratory experiment onboard Exomars 2022 mission which will be used to analyzed samples from Mars soil.

Thales Alenia Space prime contractor

Aerosapce applications, filling tanks for pressurized systems requiring extra high purity or robusteness to external evnironmental conditions

Filling valve for Ultra Clean Zone of UCZ Exomars 2022 analytical laboratory drawer

Filling valve for Ultra Clean Zone of UCZ Exomars 2022 analytical laboratory drawer