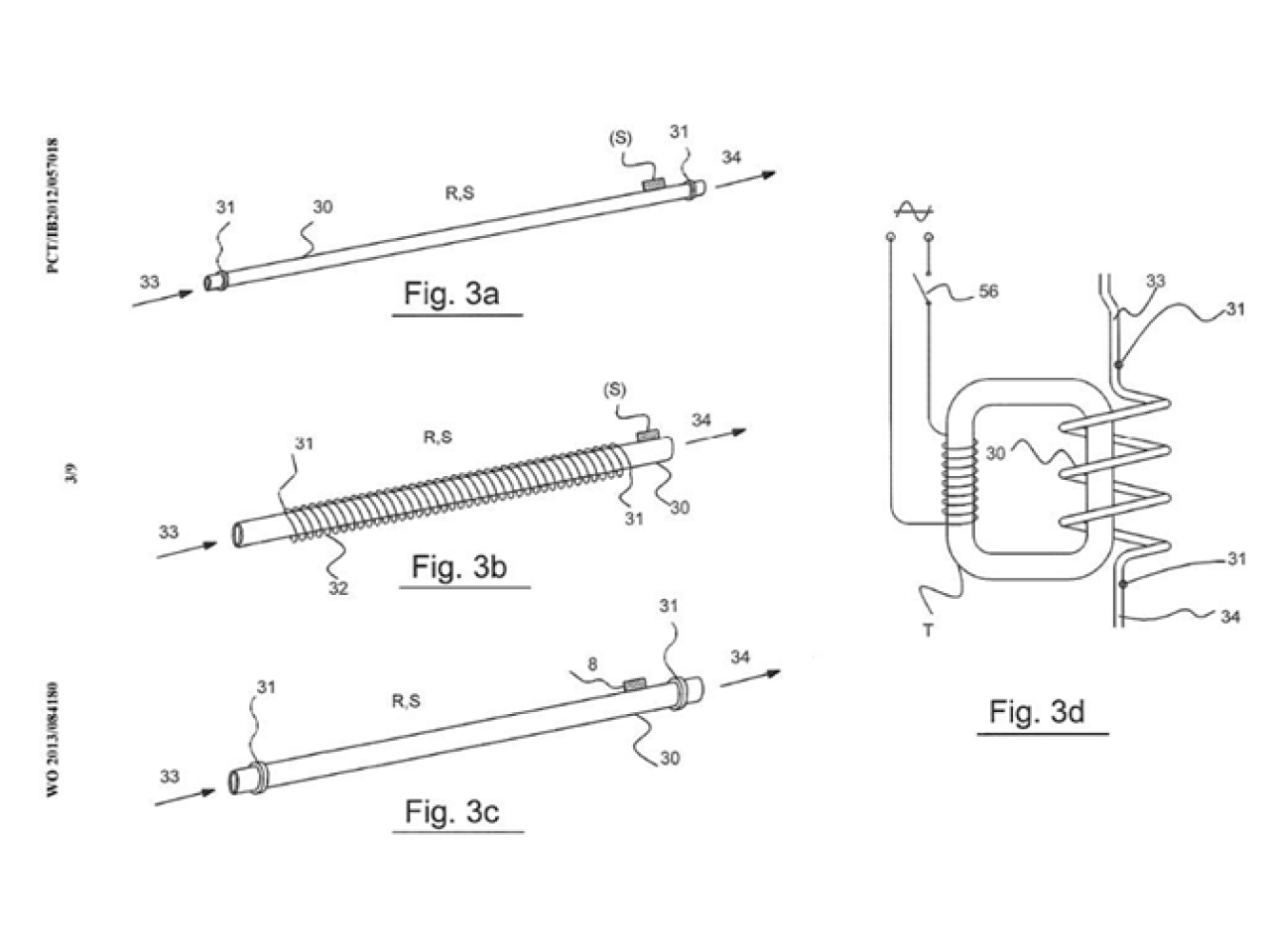

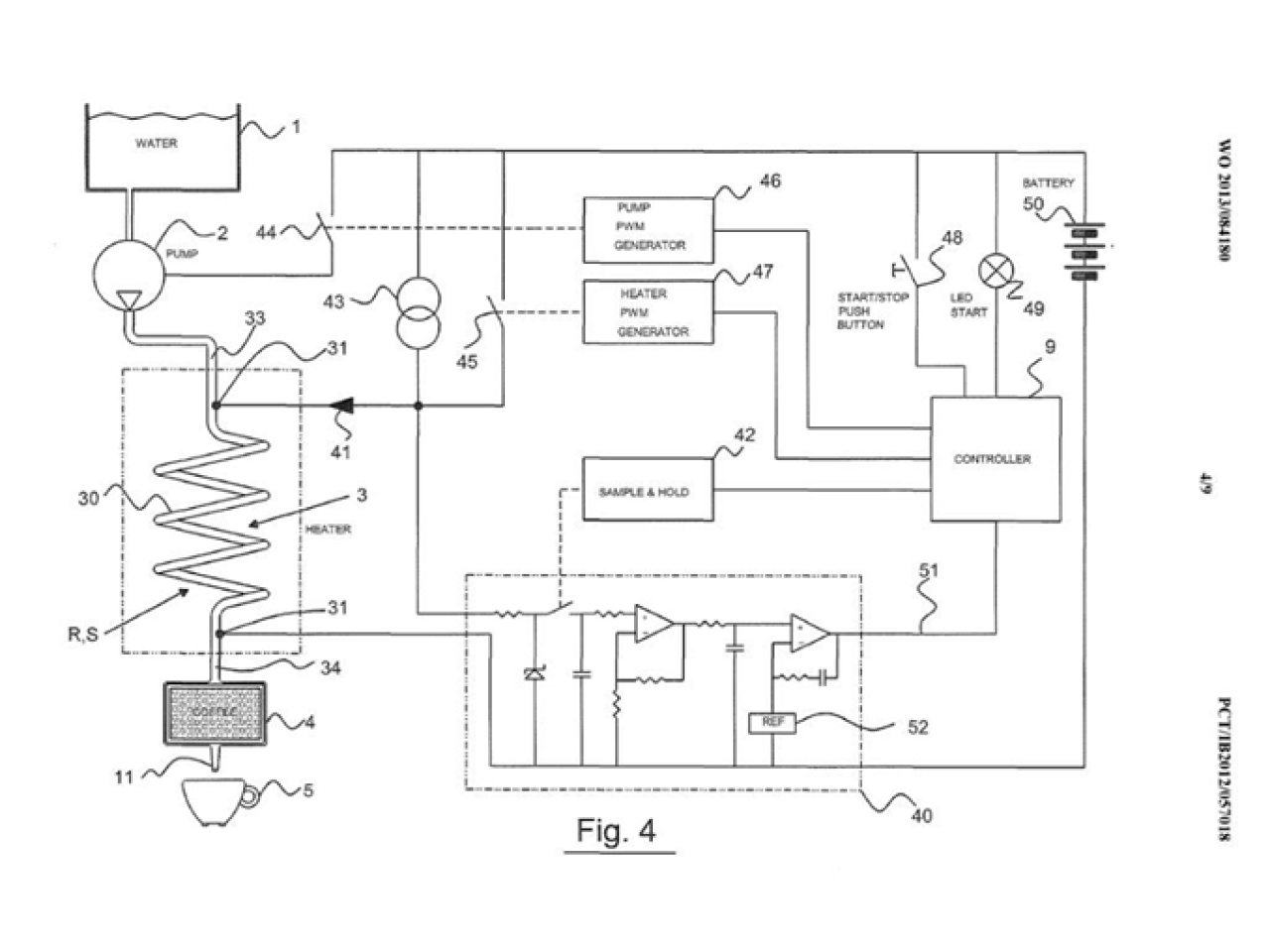

Redox has developed an immediate liquid and gas heating technology, conducive to obtaining energy efficiency greater than 90% and response time of less than one second. The technology consists in constructing a high efficiency, low thermal inertia boiler for thermal exchange and a process control electronic board. The system, covered by patent, allows pressurised liquids and gases to be heated with controlled temperature profiles, even with deeply inconsistent flow rates. Sophisticated control electronics assure temperature consistency within the pre-set values, even for quickly time-varying flow rates. By way of example, it is possible to issue hot air flows (or water, or steam) in an impulsive manner, following the pattern required by a productive cycle. This allows the medium to be heated only when it is actually required and not continuously.

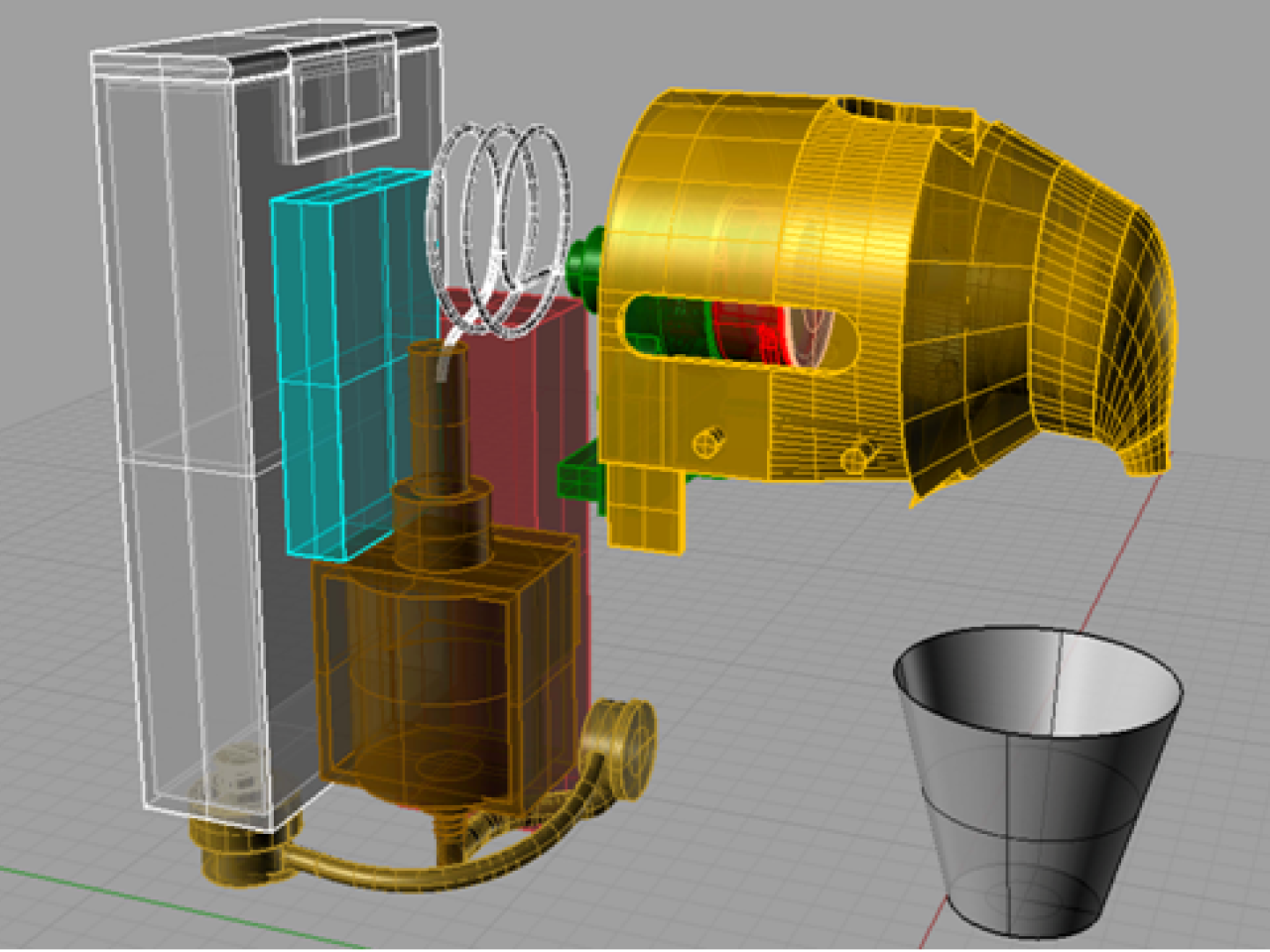

Utilisation example of the liquids heating technology; portable energy saving coffee machine

Utilisation example of the liquids heating technology; portable energy saving coffee machine

- Waiting time for fluid heating virtually zero - Sophisticated temperature control able to maintain the fluid adjusted even for time-varying flow rates. - High energy efficiency (only what is needed is heated) Technical specifications are as follows: -Operating voltage: 12V, 24V, 230V -Power input: 300-1200W at 12/24 V, 500 - 5000 W at 230 V -Fluid/steam/gas outlet temperature: from 30° C to 500° C -Flow rate: from 0.1 l/min to 500 l/min -Temperature precision: up to +/- 0.1% -Temperature correction speed: up to 1,000 times a second, with mixed feed-forward and feed-back technique. -Electronic control board: integrated -Heating efficiency: from 90% to 99%

The rapid heating technology lends itself to any kind of application, either industrial process (drying hot air, cleaning or cooking steam, thermal treatment water or oil) or consumer applications for small household appliances and battery or portable heating systems. The first application of this technology was used in developing an espresso coffee machine, which thanks to 90% greater energy efficiency is able to be battery operated.

Various implementations of the rapid water heating system

Various implementations of the rapid water heating system

Portable energy saving coffee machine

By applying the technology to an espresso coffee machine we were able to obtain over 90% energy efficiency. Conversely, the same coffee machine manufactured with conventional technology used between four and five times more energy to make one coffee. Simply put, the application brews coffee instantaneously and after brewing all circuits shut off, taking consumption to zero. With such a high efficiency, it was possible to experiment with espresso coffee production using a lithium-ion battery as the source of energy. A battery weighing half a kilo is able to produce 30 espressos. The overall weight of the machine is approximately 1 Kg. This technology therefore paves the way to producing espresso coffee with a portable device From the three samples of machines produced, we were able to produce thousand of coffees in a reliable and continuous way. The immediate water heating technique proved to be reliable and repetitive. The control electronics always worked in an excellent way. The technology is therefore ready to implement other applications in the industrial and consumer fields. The patent for the technology has passed priority tests and has been extended abroad.

Entirely developed by Redox srl

International patent no. WO 2013/084180 A1 MAIN APPLICATIONS: Steam generation Hot water generation Hot air generation Thermal treatment oil or fluid heating Generation of inconsistent flows over time

Block diagram of the "Energy saving coffee machine" in one of its possible constructions

Block diagram of the "Energy saving coffee machine" in one of its possible constructions