IPERCER has made it possible to develop a series of innovative tools for the ceramic tile industry, especially for the production of large porcelain stoneware slabs. The main phases of the production process have been analyzed to fully understand the mechanisms and to develop tools that can be used in the design and management of the production cycle, and for measurement and control of the finished product. The development of phenomenological models of the process phases, the use of numerical simulation, for predictive purposes, of behavior of the material during the production process, and for the energetic efficiency of some of its phases, the development of smart monitoring models of the energy-consumptive phases of the process, the development of measurement methods for the certification of these new products are the most significant results of the research activity carried out within the project.

Logo of the IPERCER project

Logo of the IPERCER project

The innovative aspect that distinguishes all the activities of IPERCER consists in the use of tools already consolidated in industrial sectors different from the ceramic one, to face and solve the technological challenges deriving from the production of new products, such as large ceramic slabs. Hence the integrated approach between the experimental measurements and the use of numerical modeling and simulation tools, and innovative measurement and monitoring tools for the sector.

The development of phenomenological models of phases of the ceramic production process, and simulation through the aid of numerical modeling; the development of effective smart monitoring systems; in-depth knowledge of product standards for certifying ceramic tiles for overcoming regulatory barriers when developing new products. They are all experiences that can be successfully exported to other industrial sectors.

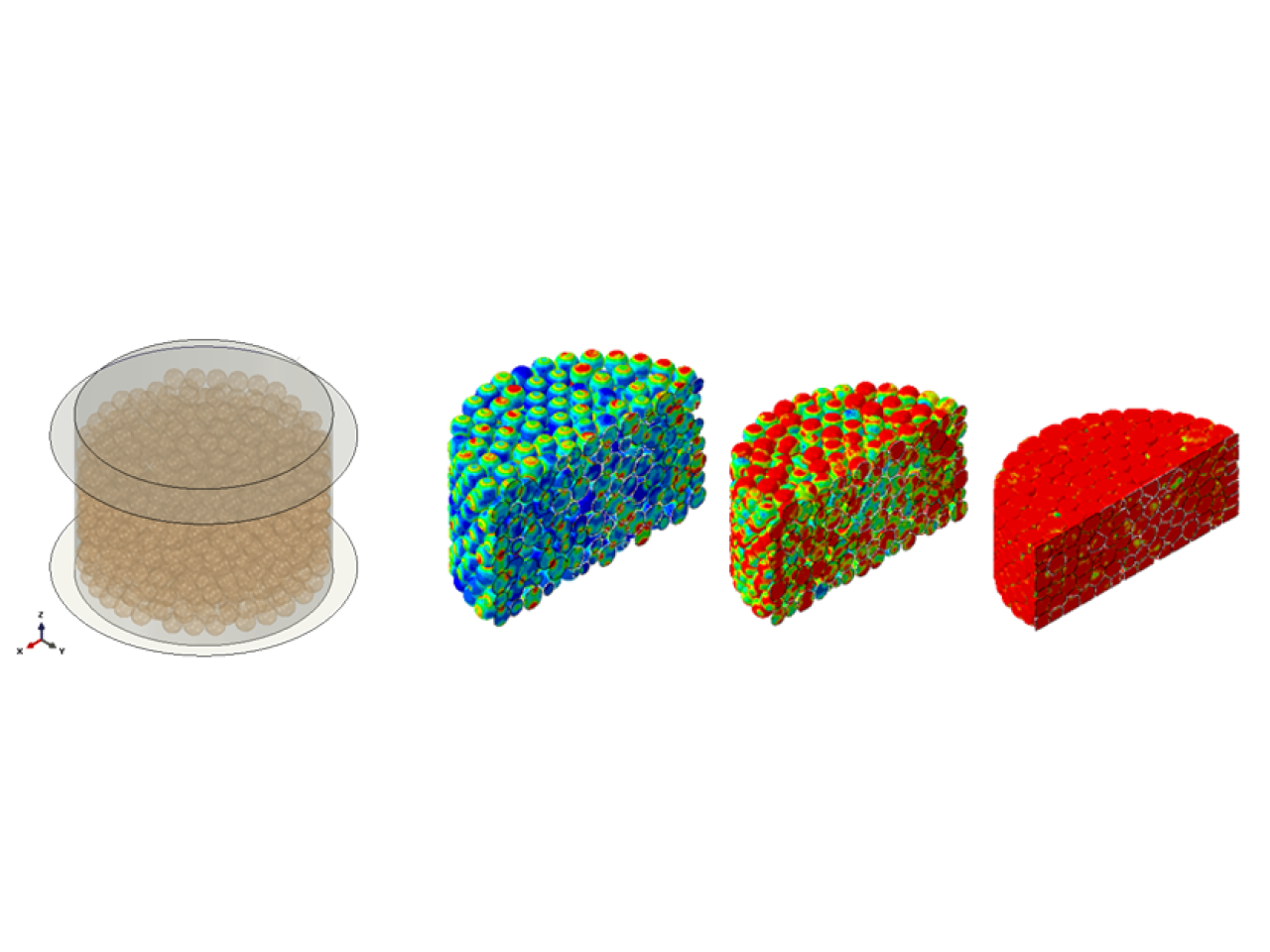

Finite element simulation of the compaction process.

Finite element simulation of the compaction process.

Definition of a test methodology for measuring off-line dimensions of large format ceramic slabs, using alternative measurement systems to the traditional ones, and developing a protocol to determine the dimensional characteristics.

With regard to measurement and control methods, the research activity has allowed to define a test methodology for the measurement of dimensions of large format ceramic slabs, according to the reference standard (ISO 10545-2), through the use of measurement systems alternative to traditional ones (e.g. data-plucometers). Innovative measuring systems have been used for the ceramic sector, already in use for decades in the advanced mechanics sector: the CMM (coordinate measuring machine) and the portable three-dimensional measuring arm with probe. An intense experimental activity was carried out, comparing the data obtained with traditional and innovative systems, extending the comparison also at international level, with other laboratories. The results obtained have shown the validity of the methods and tools used. Furthermore, we developed guidelines and a measurement protocol for large slabs, in view of an update of the standard, to be presented and discussed at international level (e.g. CEN and ISO).

Research centers: Centro Ceramico, CIRI-EC, CNR-ISTEC, CIRI-MAM, Nier Ingegneria. Companies: Gigacer, Panaria Group, SACMI, Reverse & Quality.

The in-depth knowledge of the test methods of ceramic tiles, together with the specific skills on the ceramic product and on the process features, allow to support manufacturers and regulatory bodies in the process of reviewing the standards, when, following the development of innovative products, the current reference standards are no longer adequate.

Execution of tests for the determination of dimensional characteristics of tiles using a portable three-dimensional measuring arm with probe

Execution of tests for the determination of dimensional characteristics of tiles using a portable three-dimensional measuring arm with probe