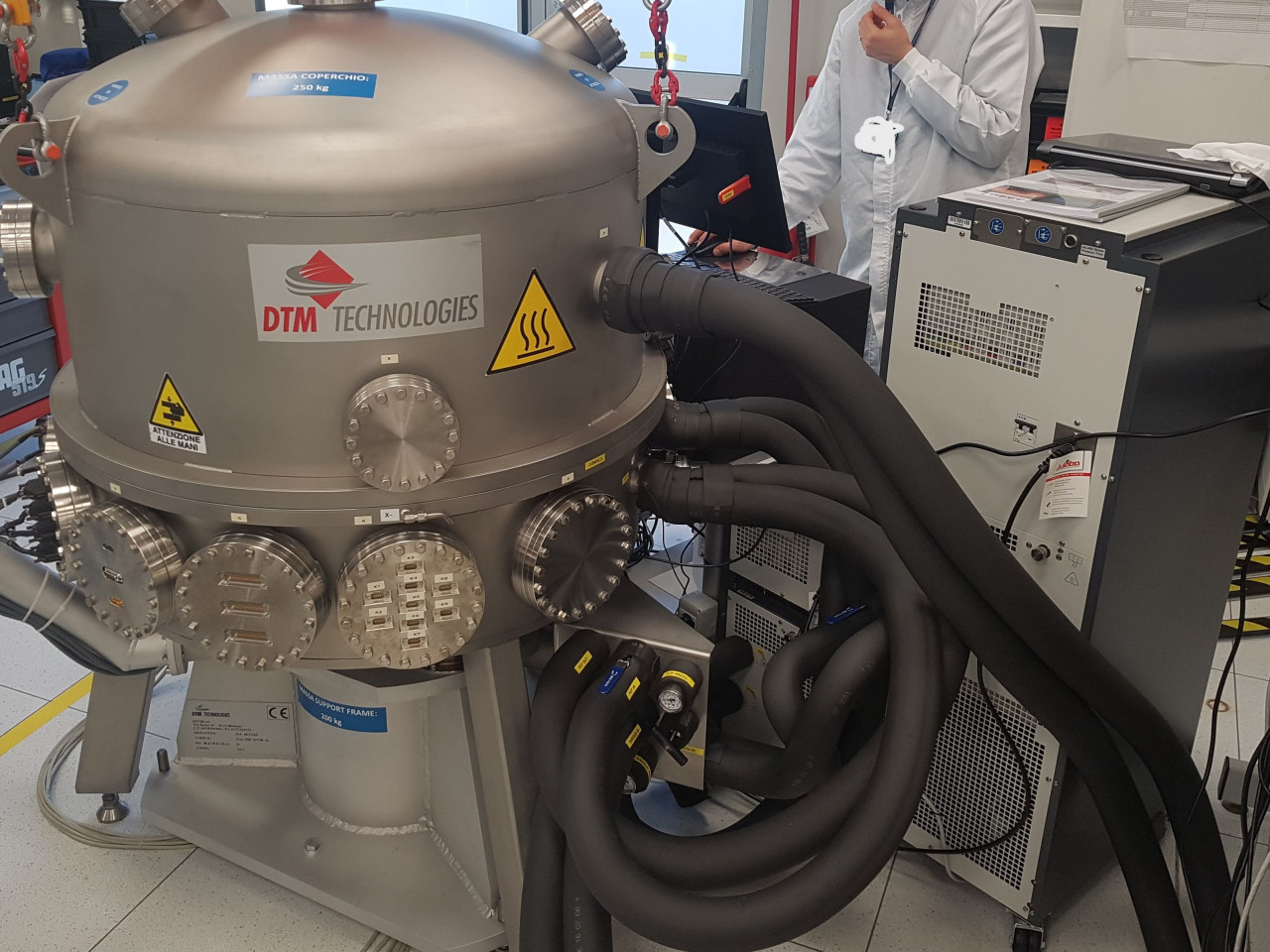

This custom GSE (Ground Support Equipment) was designed to replicate space conditions on ground (vacuum and temperature gradients) and test selected space hardware for satellites performing also electrical and optical measurements.

Mechanical/thermal/optical GSE

Mechanical/thermal/optical GSE

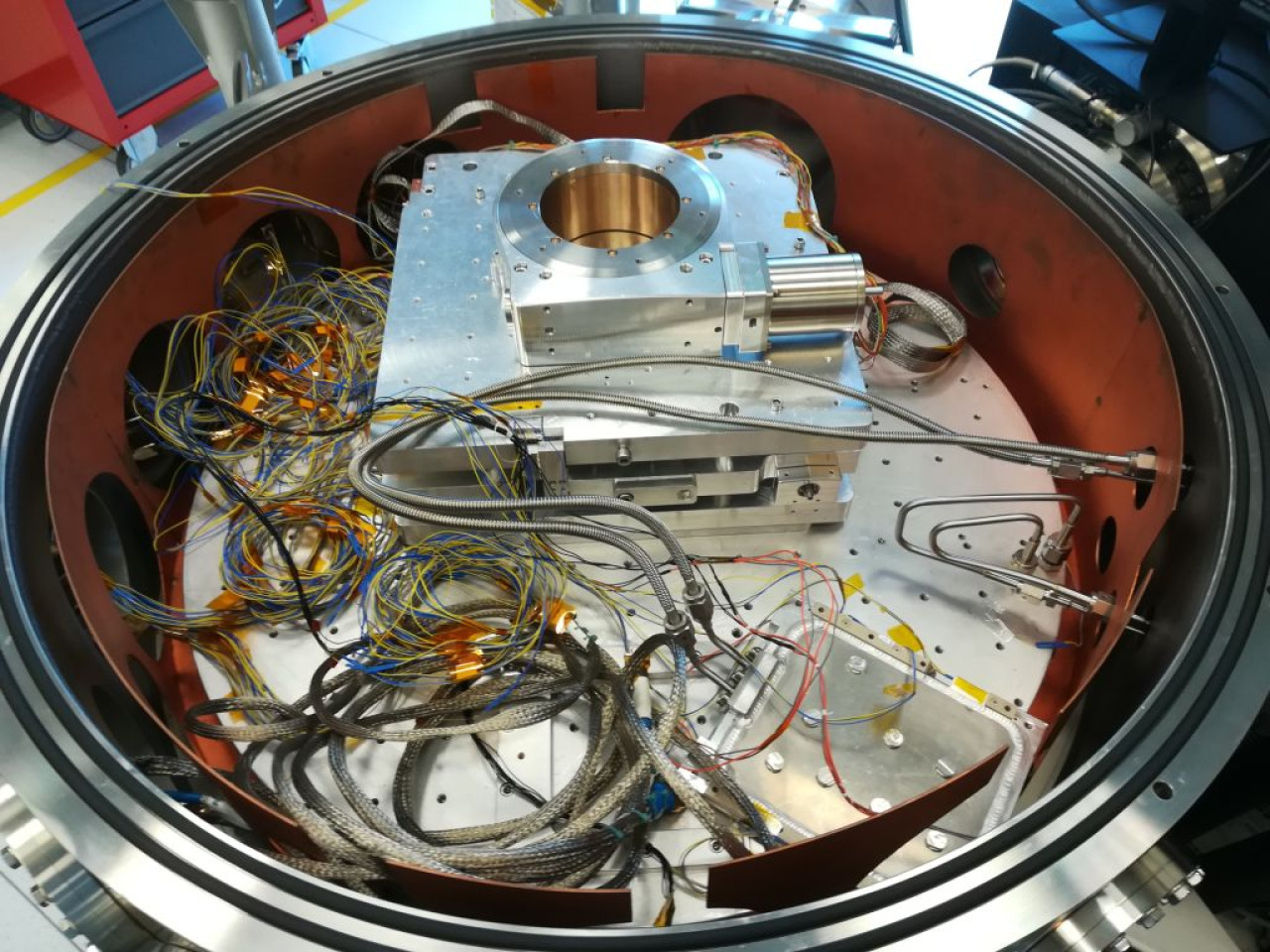

This GSE was designed to replicate the space environment on ground for satellite hardware testing. It is based on a custom vacuum chamber capable to achieve high vacuum levels in a limited time, and two temperature control units capable to independently control the temperature on two different cold plates inside the chamber. A thermal shroud is also present inside the chamber lid in order to create a radiative environment all around the unit under test. The GSE also provides all the needed electrical feedthroughs for space hardware power supply and data transmission. The main cold plate, made of aluminium alloy, can be controlled between -40 and -60°C. A secondary smaller cold plate is equipped with four attachment areas for a space hardware unit, and each one of these areas can be controlled independently between -10 and +60°C by means of liquid circulation and electrical heaters. The GSE is also equipped with a high accuracy micro-positioning system, remotely operated and capable to rotate the unit under test around all three orthogonal axes. Some transparent quartz windows are placed on the chamber lid so that the unit under test is visible from outside during thermal vacuum testing, and the system is completed with two autocollimators that can measure the angular displacements of some points of interest on the unit in the microradiant order of magnitude. This can be useful to verify the displacements and deformations of the unit and compare them with the analytic results.

This GSE is innovative because it combines several equipments together and it is possible to perform different tests (mechanical, thermal, optical) with a single GSE, remotely operating it with a single supervisor PC.

This kind of GSE can be adapted and customized in order to test several types of space hardware units (electronic, optical, etc.).

GSE inside view with cold plates and 3-axes micro positioning system

GSE inside view with cold plates and 3-axes micro positioning system

Space hardware testing and qualification for satellite application

This custom GSE (Ground Support Equipment) was designed to replicate space conditions on ground (vacuum and temperature gradients) and test selected space hardware for satellites performing also electrical and optical measurements.

Leader European company in space industry.

The mechanical/thermal/optical GSE has been operating inside a clean room environment for over 10 years for testing an instrument now flying on Bepi Colombo spacecraft. It has also been used for testing activities on parts of JUICE spacecraft, now flying towards Jupiter moons.