Metal Replacement is the replacement of metal materials (steels, aluminium alloys, cast iron...) with high performing polymeric materials. The recent developments of new and better performing thermoplastic materials allow applications to be extended to new products and sectors which used to be restricted to metal alloys. The performance of items produced in thermoplastic material is similar to that of equivalent metal ones and afford marked benefits in terms of cost and productivity. Furthermore, high performing polymeric materials make it possible to reduce weight, corrosive phenomena and offer high resistance to wear and reduction of noise and vibrations. At the same time they offer the possibility to obtain a wide range of colours and surface finishes.

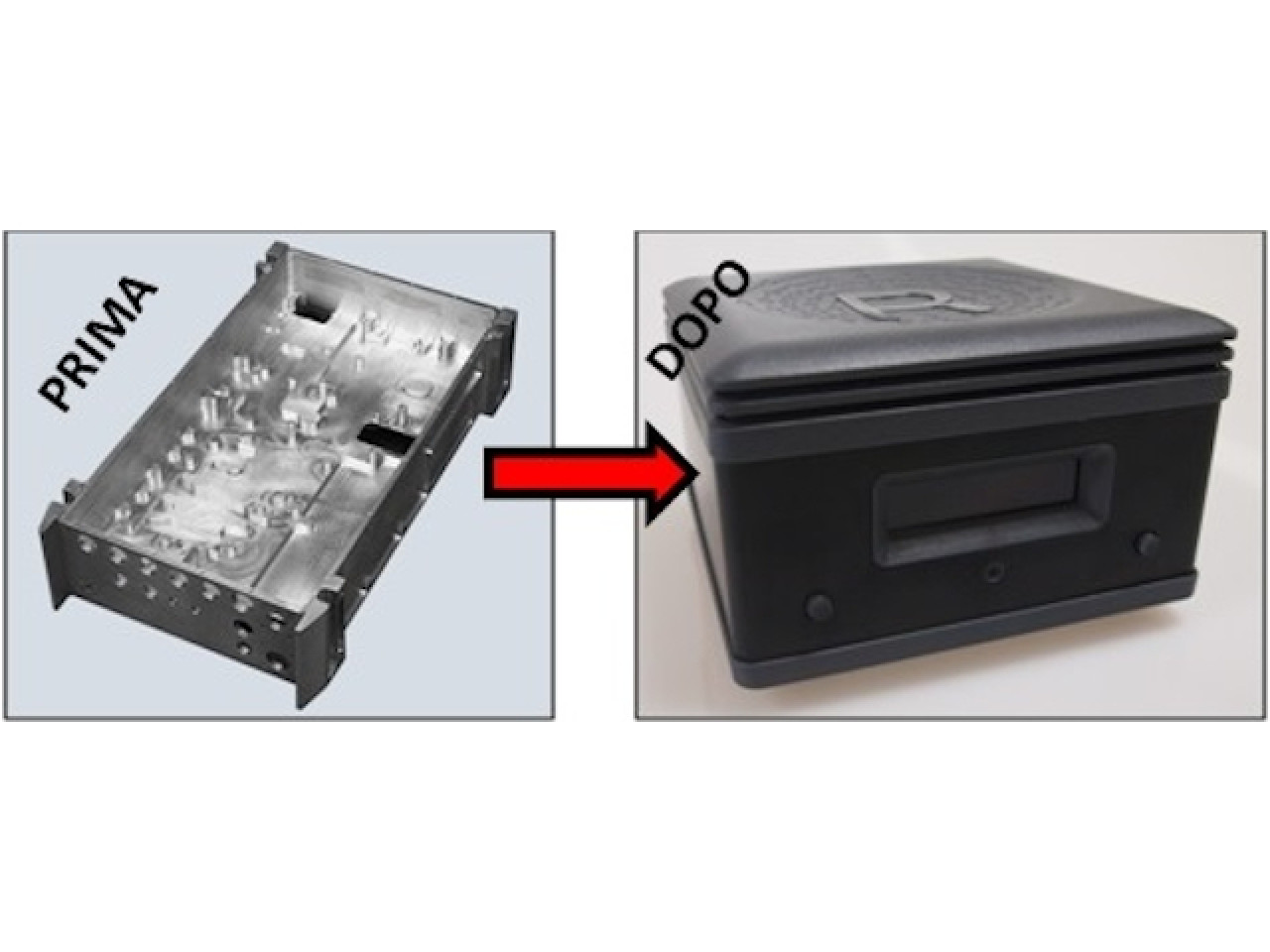

Metal Replacement example

Metal Replacement example

The use of polymeric materials to replace metals involves a number of advantages, among which: - Cost reduction and productivity increase - Weight reduction - The highest freedom in terms of shapes and design -BOM reduction thanks to bundling several components -Corrosive phenomena reduction and high resistance to wear -Possibility to obtain a wide range of colours and surface finishes -Noise and vibration reduction; -Environmental impact reduction. To make the best use of these advantages, a varyingly extensive redesign of the product is often required. In many cases redesign also makes it possible to implement new features within the product.

Metal Replacement may be applied to many market sectors, namely: Automotive and mechanics in general: light and inexpensive structural components, wear-resistant components Electronics: cases with high design value able to integrate several functions, possibility to use electrically conductive materials to avoid interferences/electrostatic discharges (EMI shielding) Biomedical: single use/durable devices such as syringes, pumps, various tools (scissors etc.) Furniture: wear-resistant components, hinges, structural components Foodstuffs: components for production lines, possible use of metal detectable materials Lighting engineering: thermally conductive plastic material heat sinks, lenses

Metal-Replacement: typical steps

Metal-Replacement: typical steps

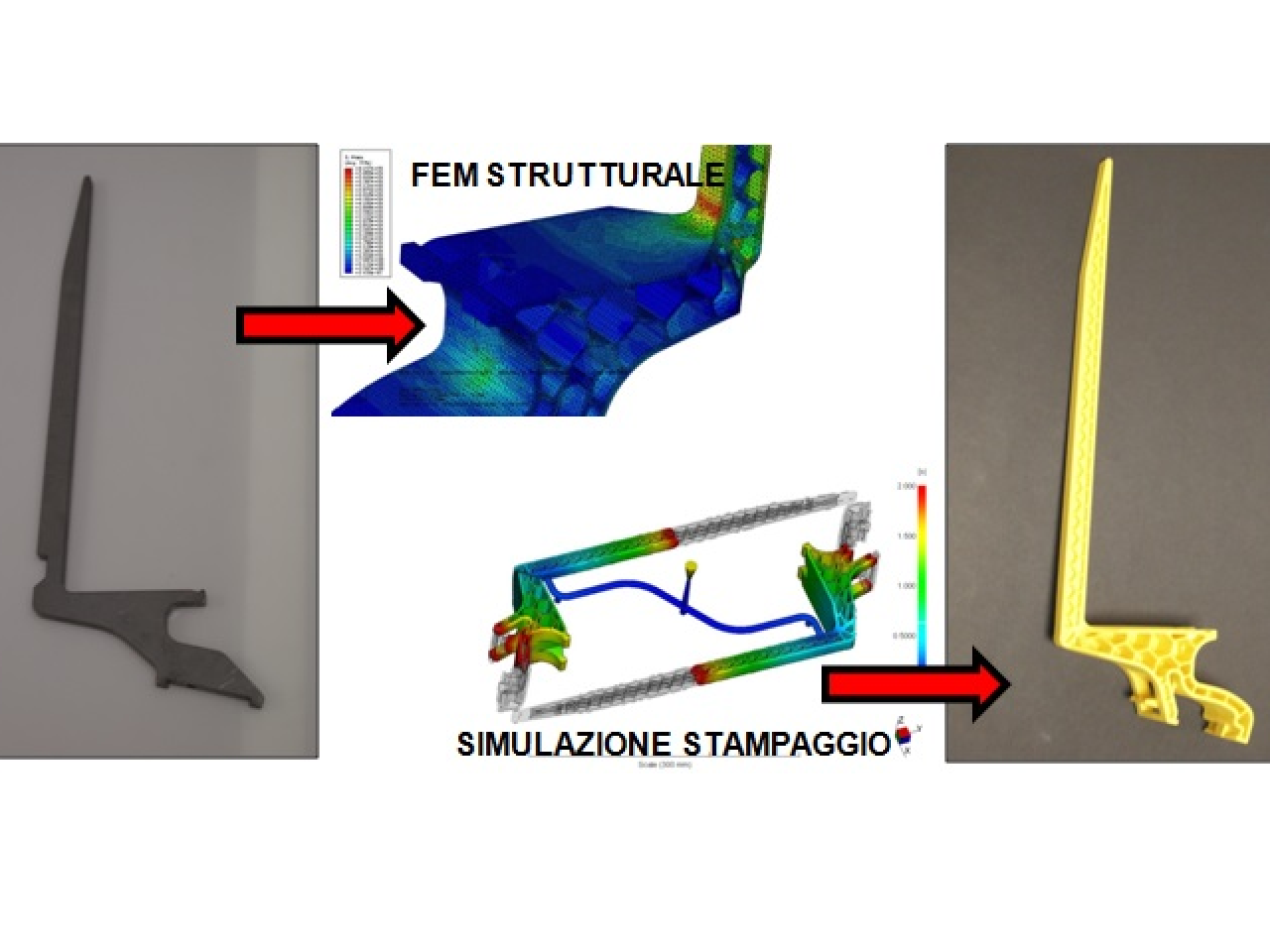

BAG DEPOSIT ROD

The project dealt with Metal Replacement of a rod to carry cement bags. The component is installed on cement packaging machines. INITIAL MATERIAL: 12mm, laser-cut steel plate installed on the line through threaded connector REQUIRED SPECIFICATIONS: Thermal resistance (-5°C/50°C) Resistance to occasional impacts Quick fastening Good dimensional stability Improved aesthetics The project involved deep redesign of the component, which allowed the threaded fastening to be replaced with a more convenient snap fastening. It was opted to use a rigid material yet featuring a certain degree of breaking elongation: PA6 30% reinforced with glass fibre and added with elastomer. Metal Replacement on this product entailed the following advantages: Cost: -50% Assembly time: -75% Weight: -72% Improvement in aesthetics The use of polymeric materials to replace steel has afforded significant design freedom, thus making it possible to obtain a product with a pleasing appearance and dyed directly in the moulding stage with the corporate colour (yellow).

Company manufacturing cement packaging machines

Metal Replacement can be extended to most market sectors with advantages in technical and economic terms.

Moulding simulation

Moulding simulation