Transparent ceramic materials are fundamental as sources of laser radiation, especially for high efficiencies and emission in the infrared wavelenghts (typically in the region of 1010 to 1080 nm). The transparent ceramic material that has reached the best level of maturity and laser performances similar to the corresponding single crystal, is the yttrium aluminum garnet doped with Yb or Nd. Unlike single crystals, obtained in limited size, the production technology of polycrystalline ceramics allows to realize large laser sources. ISTEC develops production technologies of transparent YAG-based ceramics doped with Yb or Nd, also with not uniform and controlled dopant distributions, geometries with a compositional gradient or laminated, that are fundamental to improve the control of heat transfer and thermal stresses that limit the output power.

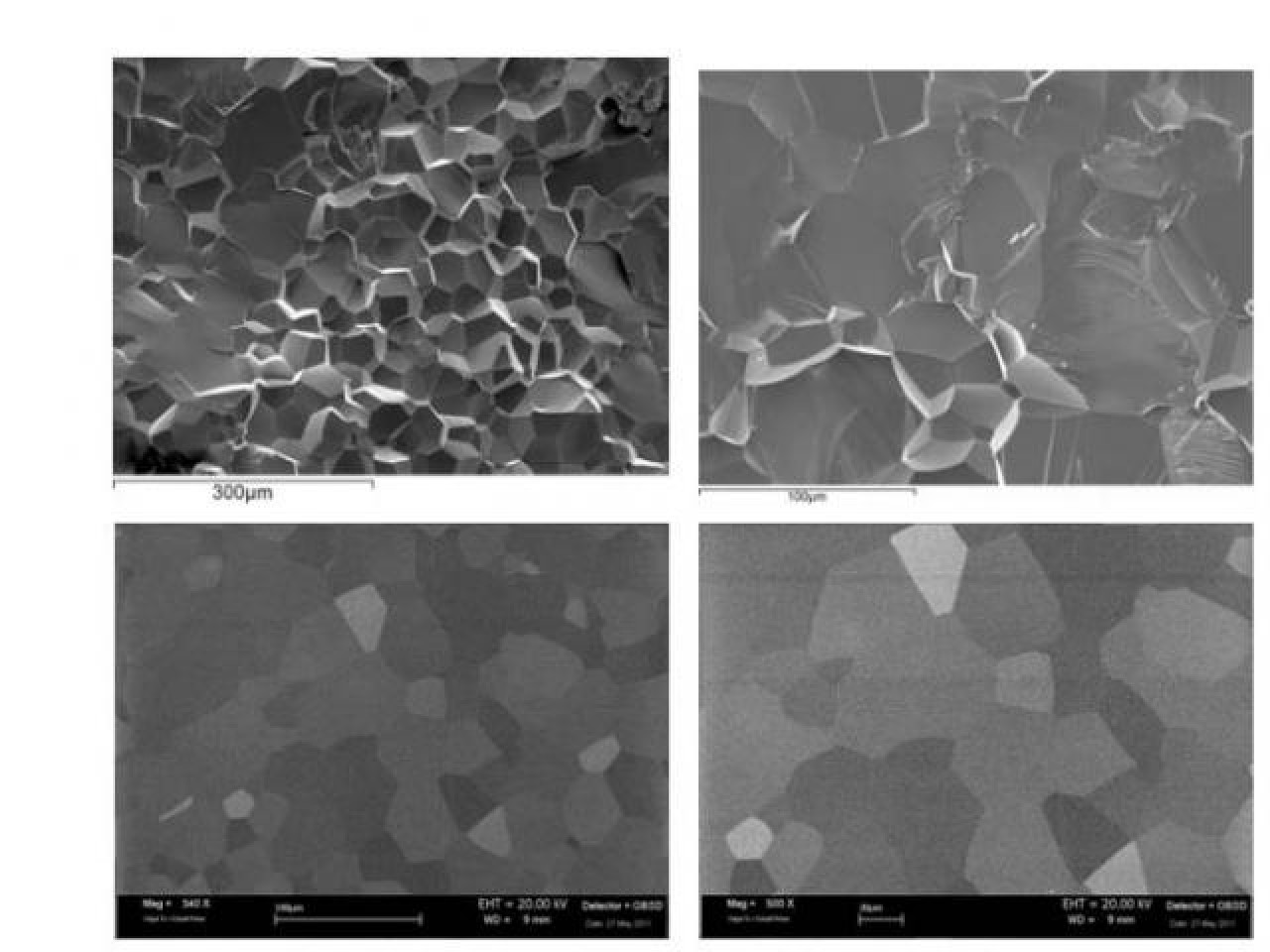

SEM micrographs of the sintered samples; fractured surface and surface after polishing

SEM micrographs of the sintered samples; fractured surface and surface after polishing

Polycrystalline laser ceramics are a very attractive alternative to single crystal laser sources: • The manufacture of components is easier and cheaper than single crystals; it is possible to produce components of large dimensions. • Due to their isotropy, the polycrystalline ceramic laser, when heated, expand in all directions and dissipate heat in an homogeneous way. Although the coefficients of conductivity and thermal expansion are comparable to those of single crystals, optical distortions are limited and the quality of the laser beam is better. • They are exploitable to produce complex structures, such as compositional gradient or laminated, they are fundamental to improve the control of heat transfer and thermal stresses.

Policrystalline diode pumped solid state laser sources (DPSSL)

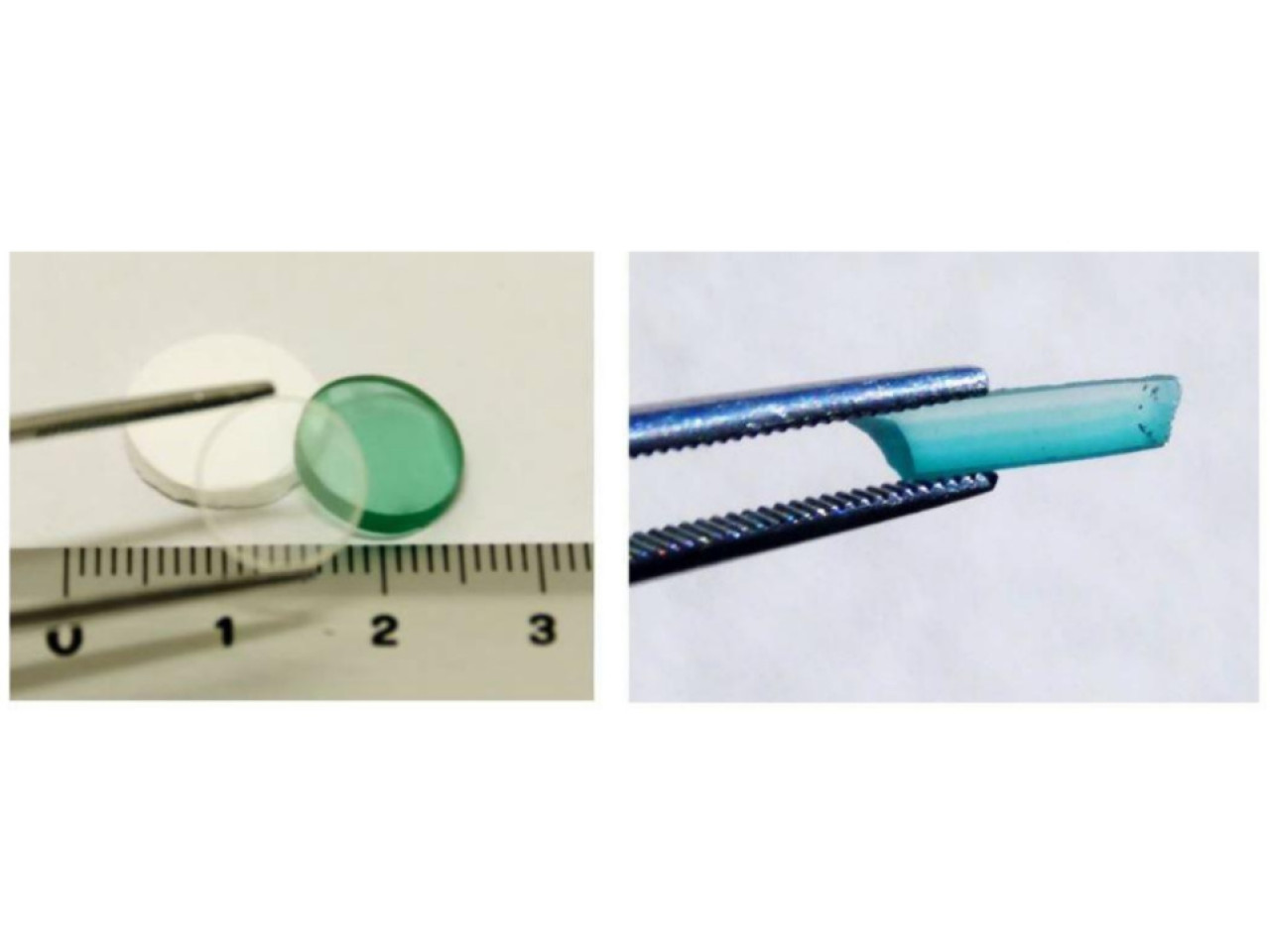

Yb3+ based transparent ceramic materials:YAG with uniform and non uniform composition

Yb3+ based transparent ceramic materials:YAG with uniform and non uniform composition

Development of an automatic laser apparatus with high operational flexibility based on YAG source (Yittrium Aluminium Garnet doped with Neodymium) polycrystalline, capable of marking, cutting, engraving and micro-drilling each type of metal

The system is based on a diode pumped solid state laser (DPSS), with high electrical efficiency and reduced maintenance compared to lamp pumped solid state laser source. The experimental work so far carried out on components based on YAG ceramic has demonstrated the technological feasibility and the ability to produce laser radiation. The prototypes were validated in industrially relevant environment in terms of laser performance (gain, extraction efficiency and wave front distortion).

AM Engineering S.r.l. (Italy) Grafos S.r.l. (Italy) RETINÆ S.r.l. (Italy) MONOCROM (Spain) GFH (Gesellschaft für Fertigungsprozessplannung) mbH (Germany) BROELL (Austria) Tridonic GmBH & Co. KG

The material has been developed and tested in the frame of several industrial research contracts, three international projects and two national projects.