The growing awareness of environmental emergencies has led companies to take urgent measures with regard to Product and Process Innovation. In this context arise GHEPI's research and analysis activities, through the “Sustainable Metal Replacement” service, in order to understand the contribution that originates from the sector's traditional behaviours change, in favor of Responsible Innovation virtuous choices. The main factors to be taken into account to determine the environmental impact in the comparison between the use of plastics and other materials are: the total mass (tons/year), the energy consumption (Joule/year) and the GHG emissions (tons/year). GHEPI's service is aimed to support Customers in Life Cycle Assessment and Eco-Design processes for Product Innovation, intended to reduce environmental impact by intervening on the life cycle.

GHEPI.Lab's R&D Service

GHEPI.Lab's R&D Service

The SMR takes advantage from factors that aren't normally evaluated in the project development process and which are represented by the Metal-Plastic comparison with respect to some fundamental elements: • Specific gravity • Melting point • Kwh/product kg • Produced carbon dioxide/product kg • Energy saving/weight reduction. Consider, for example, the differences between two factors, from which it is possible to grasp the gap in connection with the energy consumption in the early phases (density vs weight), production and processing (melting point). In a SMR project, the Life Cycle Assessment can evaluate the product environmental impact on every single phase of its life cycle: raw materials, production, supply, transport, packaging and usage, maintenance and life end (reusing, recycling or disposal). Therefore it can hilight pros and cons of different designs and alternative materials and can represent an important competitive advantage, thanks to the energy consumption optimization.

The SMR potential applications are many, largely unexplored. It comes to mechanical components and precision technical articles for the following sectors: Automotive, Railway, Electronics, Automatic packaging machines, Mechatronic systems, Automatic reading systems, Hydraulics and Pneumatics, Submersible pumps, High pressure pumps, Electric engines, Gearmotors, Internal handling and sorting systems, Medical-Pharmaceutical, Mechanic and mechatronic micro-applications, Household appliances, etc. With reference to the environmental sustainability requirement, the most important SMR factor that contrasts with the metal usage is the product weight reduction, which is a remarkable synergistic effect. It is important to notice that a SMR project is not a corrective measure or a relief to be taken if it is not possible to use metals; the specific polymers usage is a real improvement in performances.

Metal Replacement service and motor reducer gears case history

Metal Replacement service and motor reducer gears case history

Motor reducer gears for cable transport systems

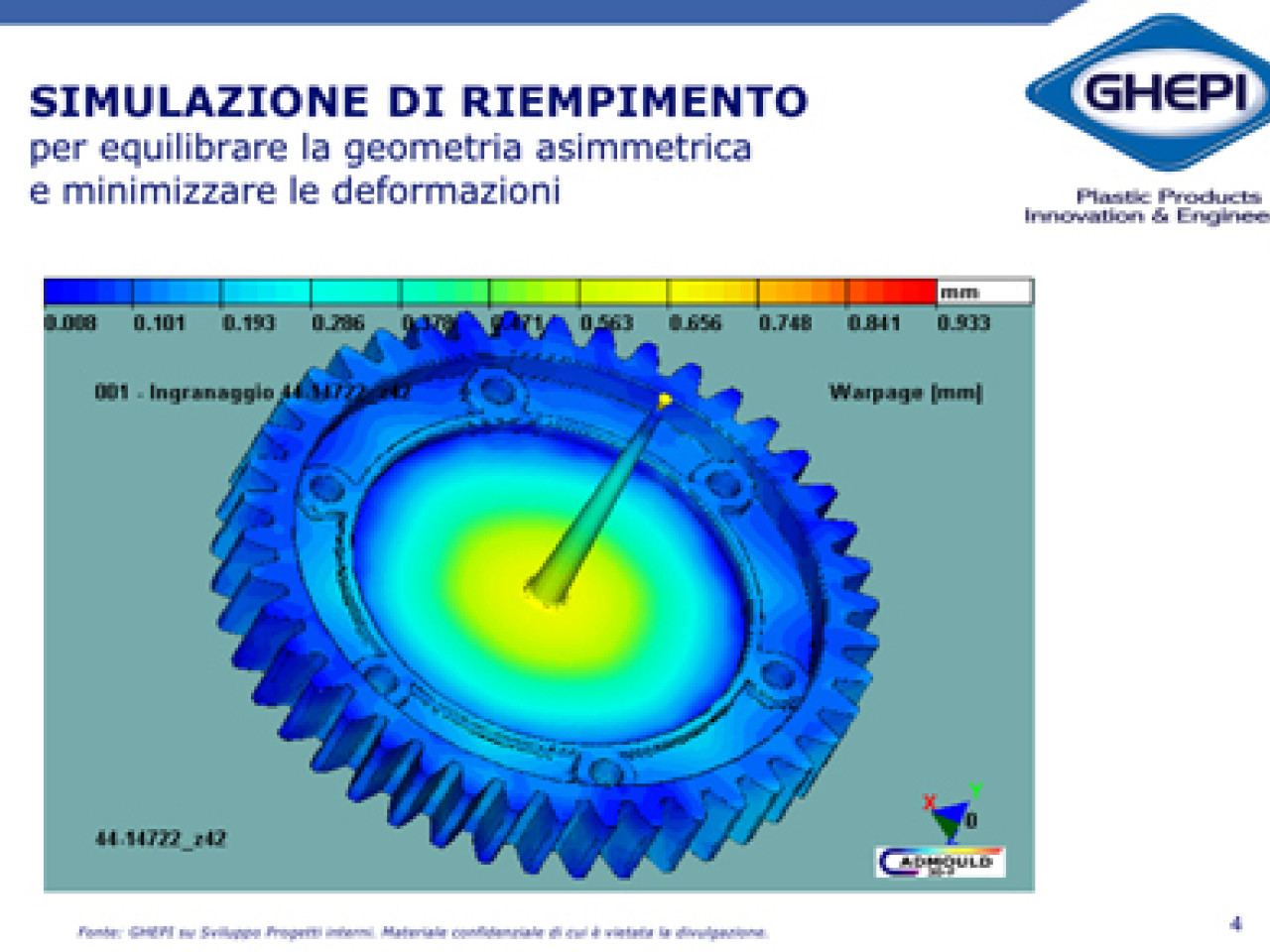

Ø300mm and Ø240mm gears belonging to a gearmotor for cable transport systems. On the basis of different speeds, the gearmotor consists of n°12 gears, which were initially made of steel. Then it was implemented a technology reverse through a RIM process (reaction injection moulding), but the related costs turned to be too high and the lead time wasn't adequated to the flexibility requirements. For this reasons the gears were reengineered according to the thermoplastics design criteria and through a deep fluid dynamic analysis that examined flows, shrinkages and deformations for the injection moulding technology. The feasibility analysis led to the selection of two high performance polymers with different but complementary features, in order to allow gear couples to work in the best conditions. In particular, they were a PA MXD6 and a PA66 with ad hoc additives and fillers. Project requirements: • High dimensional stability. • Wear resistance. • Mechanical features retention with temperature range between -30° and +60°. Critical issues: • Deformations, fillings, shrinkages, tolerances and air inclusions determined by high thicknesses and figure asymmetry. • Experimental and experiential definition of the compatible materials with the gear couple. • Removal of the gear periodic lubrication need. • Cost reduction by 25%, mould amortization included. • Substantial lead time reduction, thanks to the elimination of phases and sequential processings. • Orders flexibility with respect to 12 gear versions (different diameters and materials).

Confidential information

Thermoplastics are "young" materials, but the intense scientific and sperimental research activity has led to the development of very interesting polymeric bases, compounds and formulations for the industrial applications that were once metals monopoly. The SMR is a concrete opportunity to achieve notable results in new products development, at overall performances and cost saving level, thanks to the resources rationalization.

Ø300mm and Ø240mm gears for motor reducers

Ø300mm and Ø240mm gears for motor reducers