Thermocert

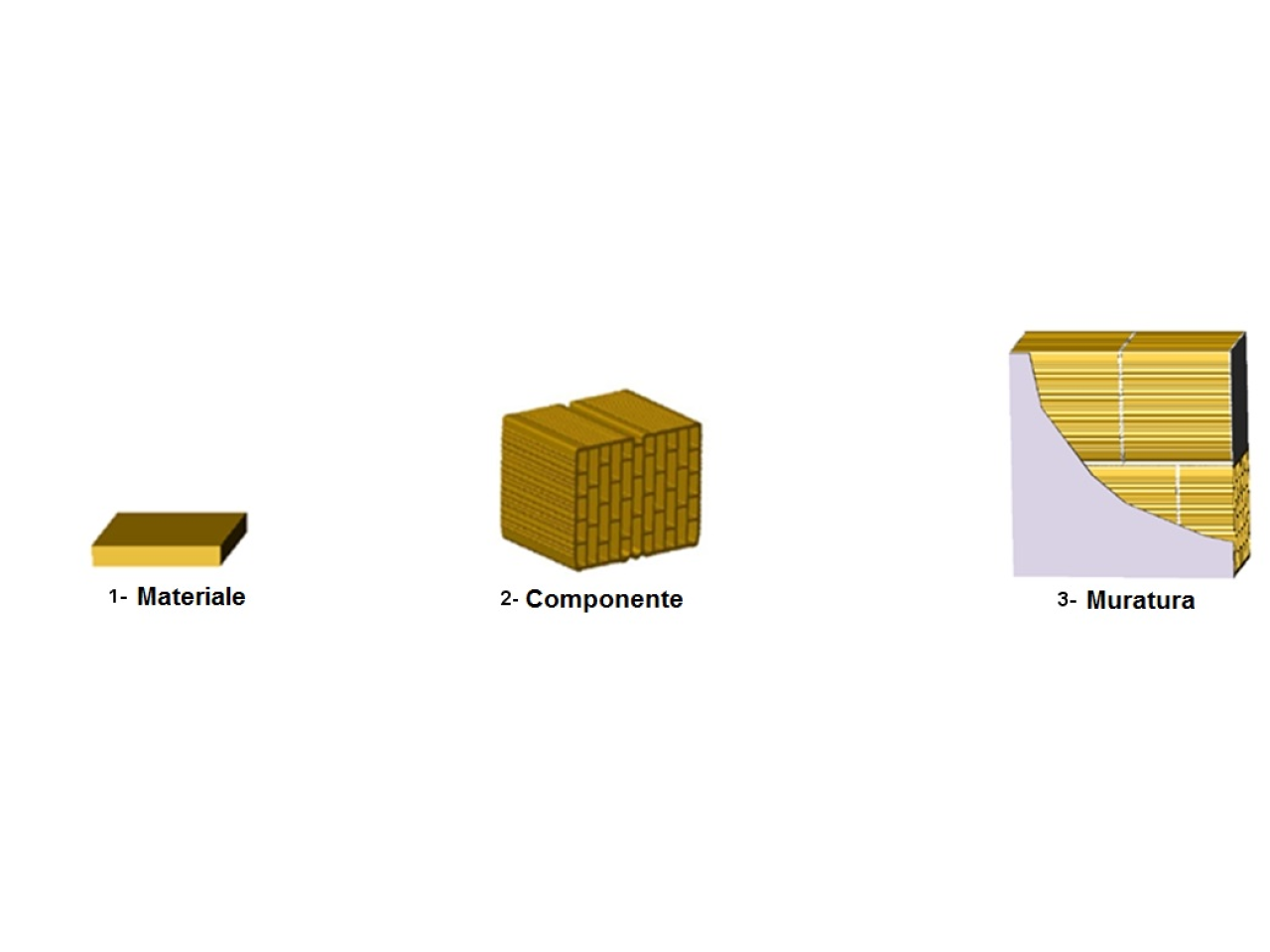

Schematic image about building process implemented by Thermocert

Schematic image about building process implemented by Thermocert

The methodology allows to characterize a material/component/envelope from a thermo-physical point of view. The opportunity to test with experimentally the value of thermal conductivity on small specimens allows to sample materials directly by element industrially made and to notice possible anomalies of performance on the productive process, guaranteeing a reliable basis for measurements on a larger scale. The developed FE models allows to model in a predictive way the thermal behaviour of single elements and building envelopes (reducing times and production costs of prototypal elements).

The set of service made available by Thermocert can be applied on all systems designed for building envelope, vertical and horizontal: - Materials and elements for load-bearing or infill wall, including insulating materials and coatings and finishing layers. - Materials and elements for underfloor systems with bearing capacity, insulating and load distribution function or with function of support to underfloor or with covering/finishing function. FE models allow to evaluate materials performance in case of heating/cooling underfloor systems. - Design /requalification of buildings

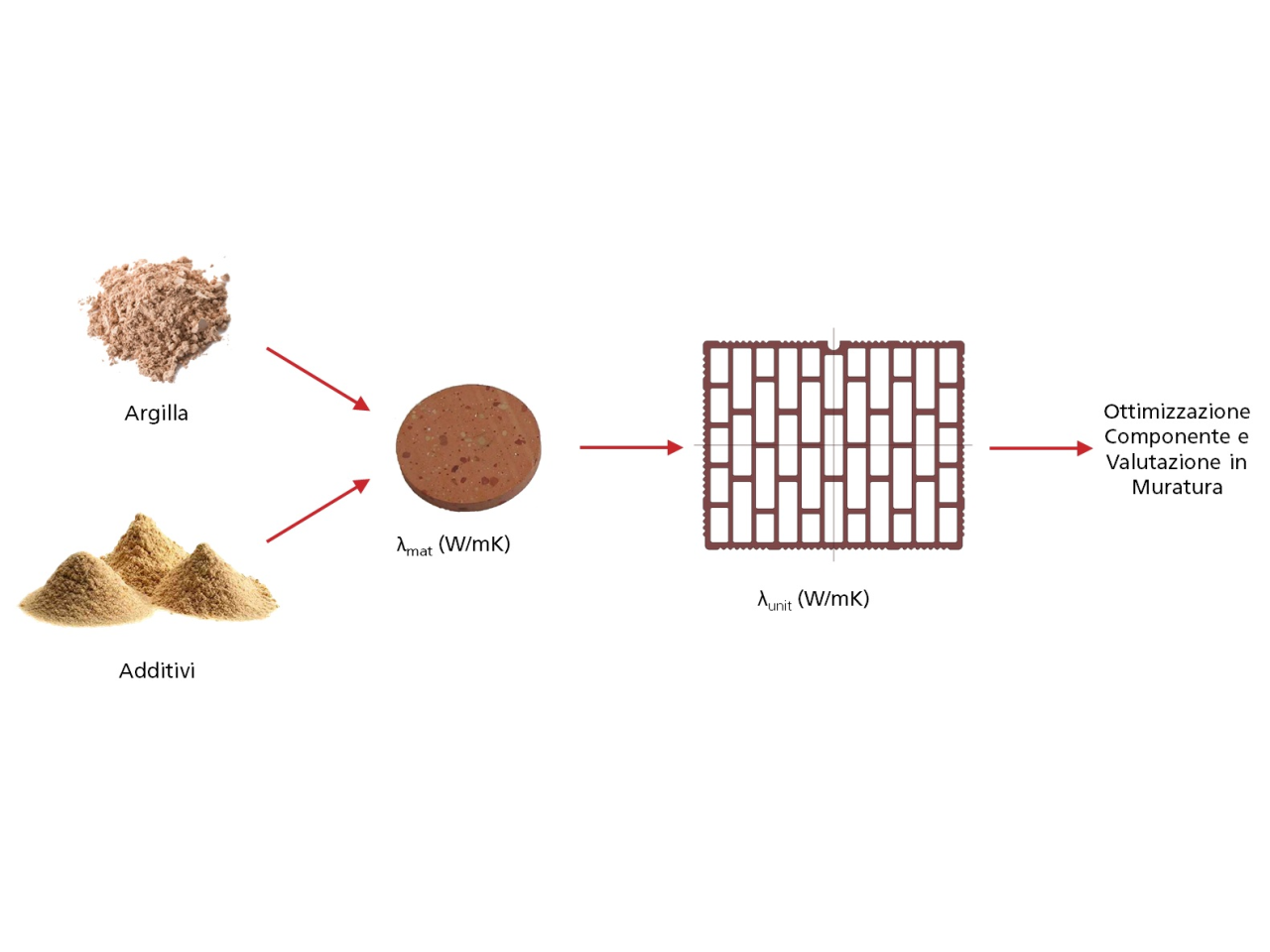

Schematic image about method's applicative example

Schematic image about method's applicative example

Financed Research project for the development of prefabricated construction systems with high thermal performances.

Thermocert considers applications both in research and industrial sector. One study-case regarded the development of new construction systems made by an insulating shuttering EPS based and a concrete core with controlled composition. The activity was devoted to an important company operating into prefabricated concrete sector. The method's application has allowed: -to perform analysis of concrete's formulations used; -to evaluate thermal-hygrometric interaction with insulating material; -to evaluate the effect of humidity on performances -to figure out the optimized layout by means of FE modelling implementation to different kinds of masonry and structural layout. This step allowed to optimize thermal bridges and reduce the critical section subjected to condensation risk; -to verify the performance of building envelope made by the new construction system and the validation of the models. Thermocert solution was been validated by means of several scientific partnership both Italian and foreigners: -Experimental measurement of thermal conductivity: comparisons with Italian university, including UNIBO, round-robin tests with French CTMNC partners and uncertainty measurement analysis with INRiM (Torino). -Numerical modelling and analysis of interaction between building and technical systems: comparisons and simulations with ENEA on modelling and energy efficient issues.

ENEA is the National Agency for the new technology, energy and the sustainable economic development.

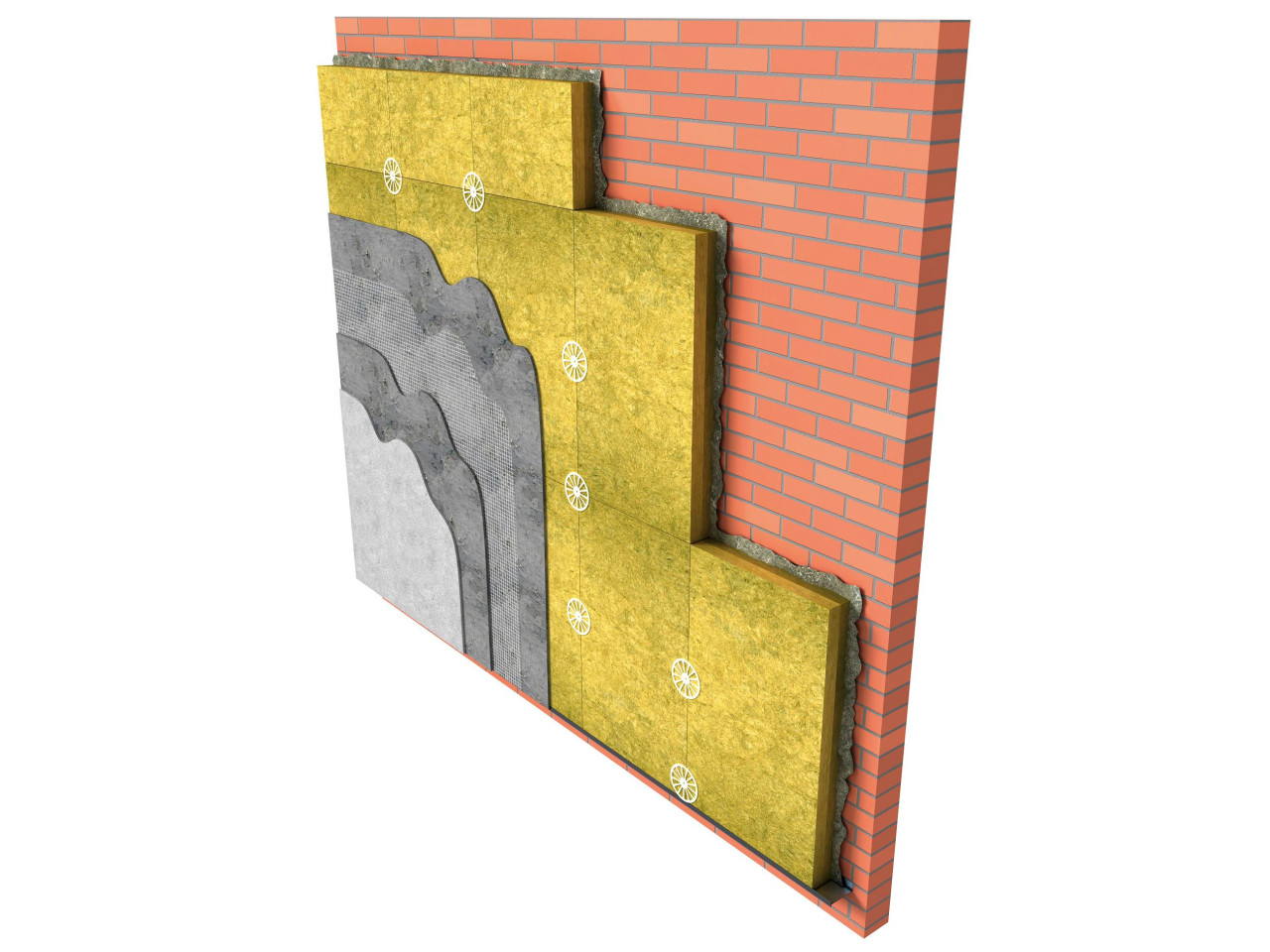

More than thousand materials tested from 2008 up to now. Approximately 100 manufactures for building envelope developed and optimized, according to cogent acceptance limits imposed by Italian and European legislation.

Detail of multilayer masonry with high performance

Detail of multilayer masonry with high performance