Especially over the last few years, the aspects connected to vibro-acoustic issues have been playing a key role within the design pathway of industrial products and machinery. In particular, following regulations that limit the emission of vibration and noise, vibro-acoustic optimisation of products is becoming increasingly important. Furthermore, it should not be overlooked that high levels of vibration may lead to faults, malfunctioning and early breakdowns. In this scenario, the MechLav Laboratory offers a vibro-acoustic optimisation service of industrial products and machinery by using sophisticated simulation and experimentation techniques and the skills of a specialised team. The service is not limited to conducting simulations or experimental analyses, but provides support to company personnel and the transfer of the necessary know-how for further product development with an analytical approach.

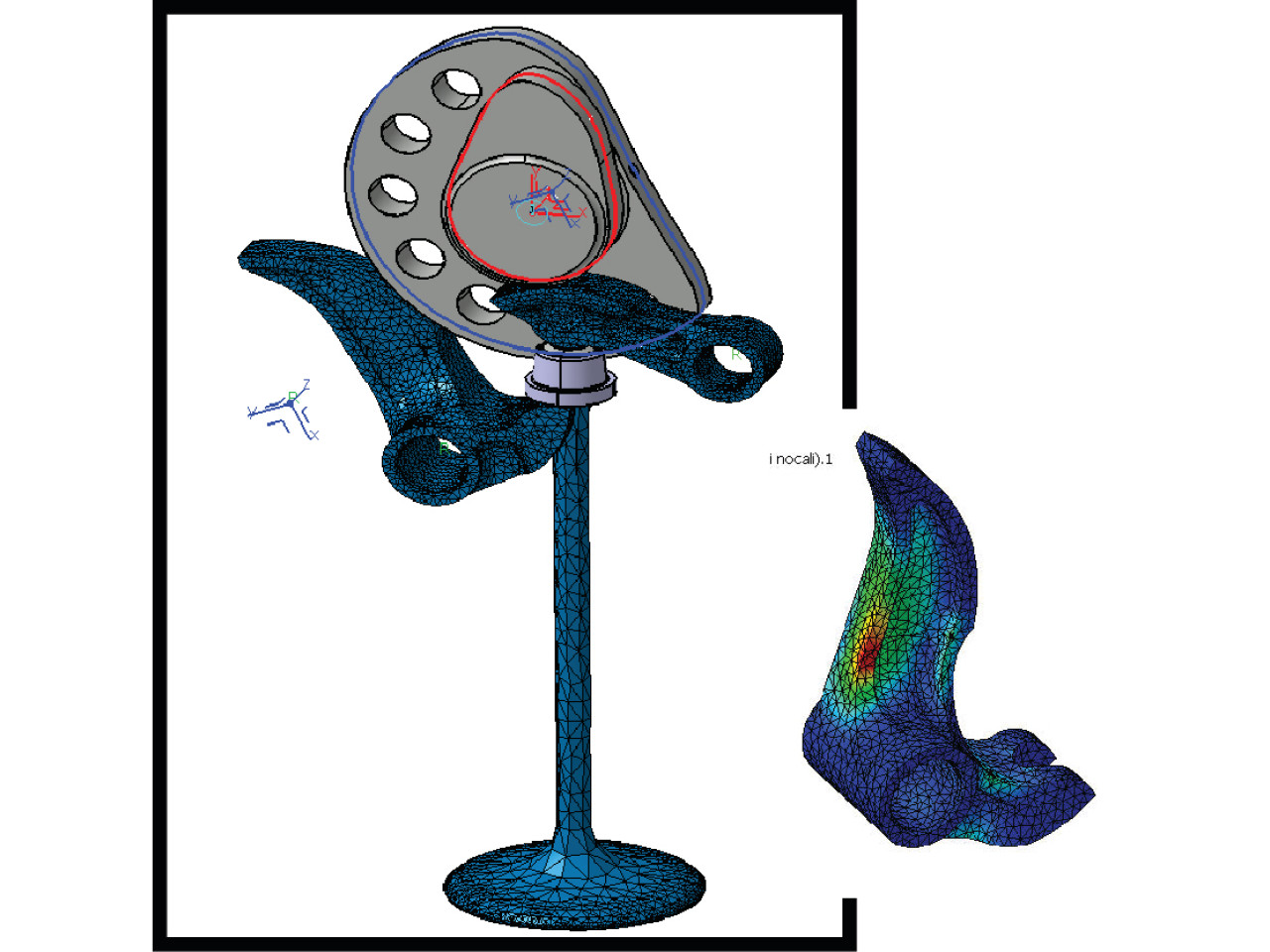

CAD Geometry of a motorcycle's timing system

CAD Geometry of a motorcycle's timing system

The use of a model allows the vibro-acoustic behaviour to be estimated with no need for making a prototype; moreover, it makes a reliable noise and vibration estimate possible in points not experimentally accessible (just think of the vibrations of moving gears inside a gearbox). The simulation also allows vibro-acoustic aspects to be estimated in any operative condition in terms of operating speed, temperature, etc., for which testing becomes problematic or even infeasible (cost of the testing plant, safety issues etc.); finally, the combined use of experimentation and simulation techniques makes it possible to appraise the actual nature of vibro-acoustic issues and therefore aids in fully resolving them.

Vibro-acoustic optimisation may be applied to all types of machines and industrial products in all mechanics sectors and not only. The research group's considerable experience has allowed it over the years to address and solve issues concerning gear pumps, vane pumps, industrial handling robots, automatic packaging machines, automatic machines used in the pharmaceutical industry, sports equipment (exercise bikes, treadmills), sports gear (tennis rackets), internal combustion engines and relevant components, cars, tractor cabs, wind turbines, hybrid cars, industrial motion wheels, helicopter cabins, pneumatic tools, motorcycle engines, gearboxes, bearings, sprockets, bending presses, pasta production machinery, suspension systems for seismic uses, gardening equipment.

Finite element simulation of a motorcycle's timing system

Finite element simulation of a motorcycle's timing system

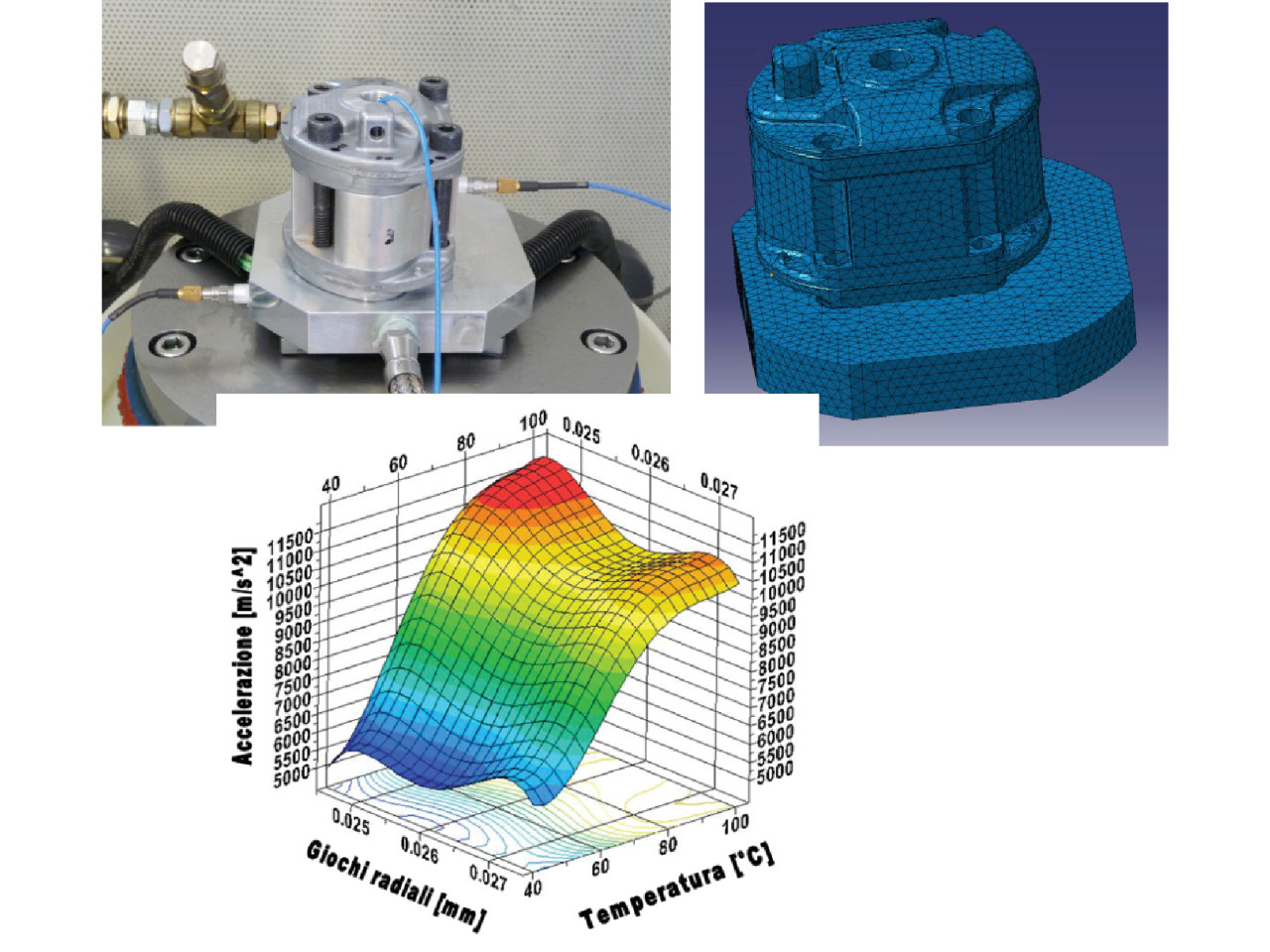

Vibro-acoustic optimisation of gear pumps for automotive applications

In the Automotive sectors, vibro-acoustic issues are deemed essential, since they alter the actual comfort level of passengers inside the car while driving. TRW Automotive Italia S.r.l has decided to contact the MechLav Laboratory of the Ferrara Tecnopolo with the aim of reducing the vibro-acoustic emission of their gear pumps employed in power steering systems for vehicles. The work led to the implementation of a number of ameliorative design solutions from the vibro-acoustic point of view. With the research group's assistance, the Company was able to interpret the results and thus identify the most effective solution among proposals.

TRW Automotive Italia S.r.l., Division Automotive Pumps

MechLav is interested in developing this type of projects with other Companies, aimed at vibro-acoustic optimisation - by using innovative analysis methodologies and tools and with know-how transfer to the company's personnel.

Dynamic simulation of a gear pump

Dynamic simulation of a gear pump