Use of transparent coatings made with natural polymers (alginates) able to convey natural molecules with antimicrobial activity, such as essential oils, for slowing down the contaminating and altering microbial proliferation in chicken breasts. The coating is directly sprayed on the product in the packaging stage and its formation is virtually instantaneous. The product maintains its natural aspect, practically indistinguishable from the untreated one. However, the two differ in the substantial slowing down of microbial proliferation, which makes it possible to extend chicken shelf-life by at least two/three days without adopting any special packaging solutions and techniques. The advantages of this application consist in the extreme cost effectiveness of the process, which does not require adopting complicated and costly packaging equipment and machines

Alginate used to prepare the edible coating

Alginate used to prepare the edible coating

They may be summarised in some fundamental points: all the ingredients used are of natural origin the process is conveniently implemented in any existing packaging line low implementation and management costs the process represent a possible alternative to atmosphere replacement techniques, which are usually associated to high plant, packaging materials and gas costs.

The innovative features of the surface coating make it applicable to a diverse range of foodstuffs: fresh beef, pork and poultry ready-prepared fresh fruit and vegetables fresh cheese. These features also allow the type of active substances to be changed depending on the specific requirements of the food.

Plastic materials for food packaging

Plastic materials for food packaging

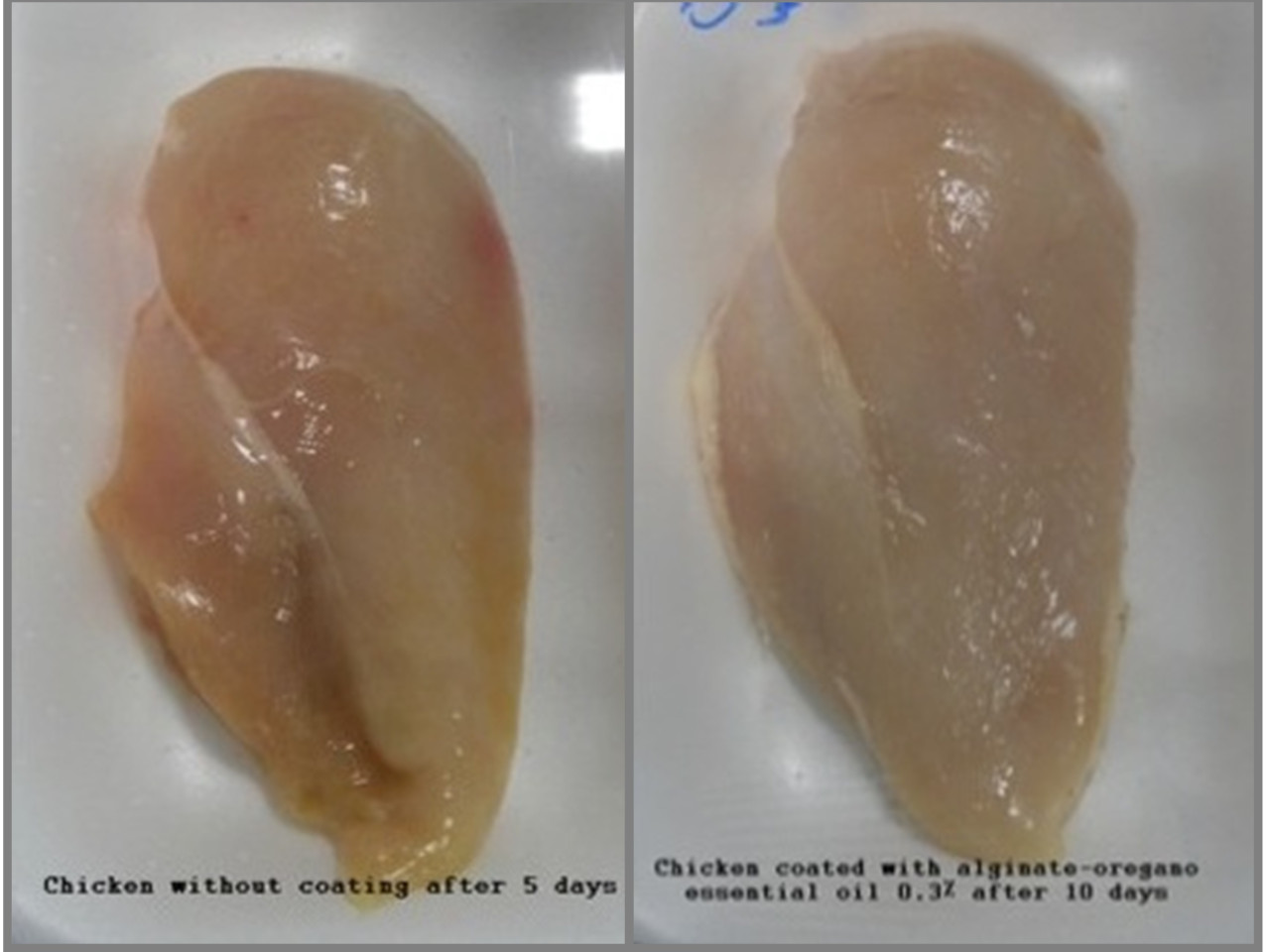

Chicken breasts coated with alginate with the addition of essential oregano oil

An aqueous suspension of alginate added with essential oregano oil was sprayed on fresh chicken breasts. This essential oil features proven antimicrobial effectiveness and a sensory profile which is well suited to chicken meat. After being coated, the chicken breasts were packaged in air on polystyrene foam trays using the company's stretch wrapping packaging line. The shelf-life of the coated chicken breasts - assessed both from the microbiological and sensory point of view - doubled compared with that obtained for this type of product with conventional technologies.

COOPBOX GROUP S.p.A., Company in the poultry sector

The results obtained consolidate the collaboration relation with the company COOPBOX GROUP S.p.A., paving the way to further in-depth studies on edible coatings

Chicken breasts with (on the right) and without (on the left) antimicrobial coating

Chicken breasts with (on the right) and without (on the left) antimicrobial coating