The common digital color photographs or the RGB images acquired by a desktop scanner can be processed in order to extract "information" on the characteristics of the sample. Such characteristics may concern the chemical composition of the sample, if it is related to its color, the presence of possible defects or different quality aspects. In this context, the CHIMSLAB research group of BIOGEST-SITEIA has already successfully implemented several studies, including: classification of pesto sauce samples of different brands prediction of the content of pigments in samples of pesto sauce identification of the "red skin" defect in pork legs identification of the variety and ripeness of Lambrusco grape samples prediction of the roasting degree of ground coffee

Flatbed scanner modified for the acquisition of coffee images

Flatbed scanner modified for the acquisition of coffee images

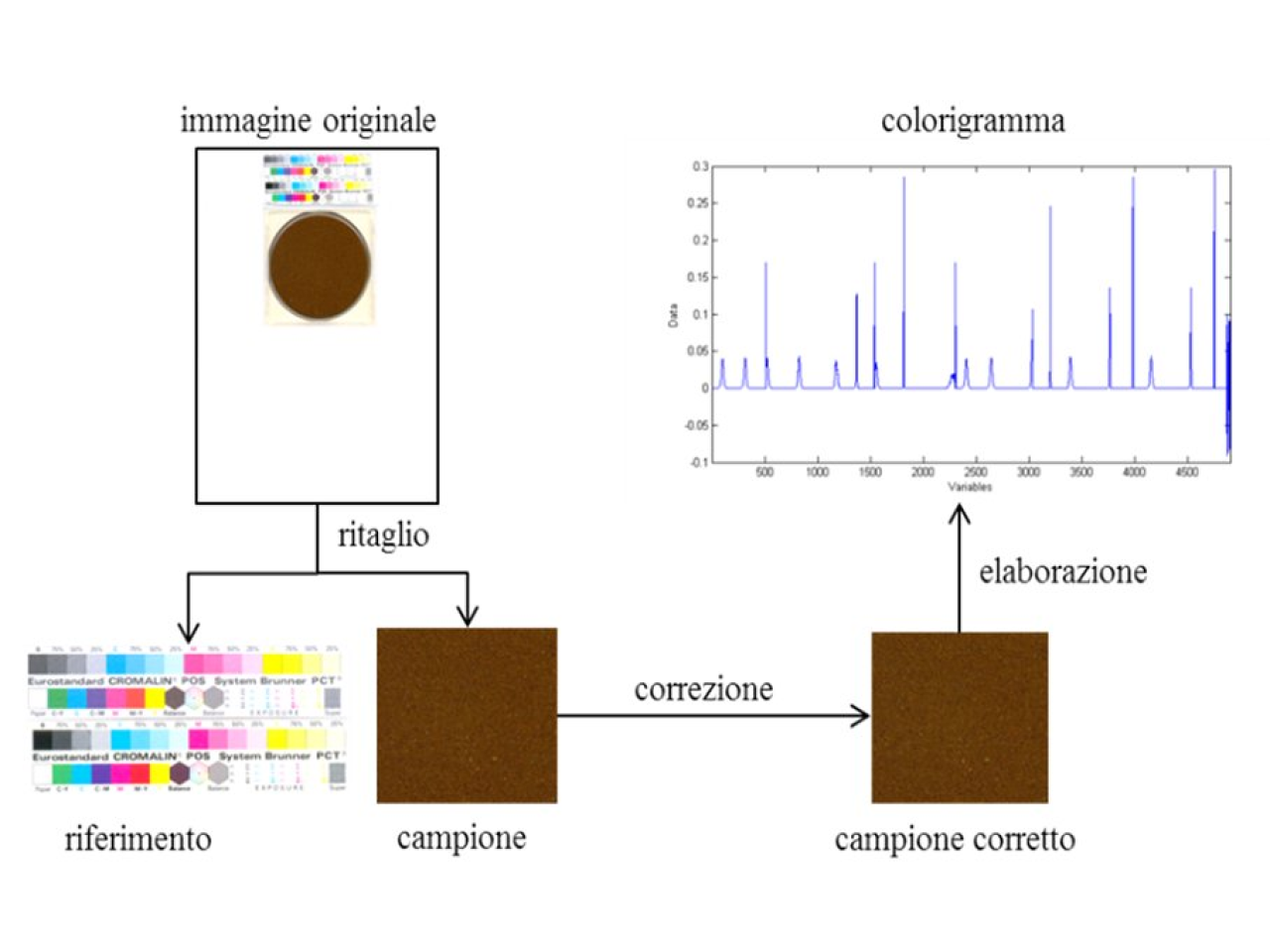

The method of image processing developed by CHIMSLAB is conceived to convert the common RGB images into one-dimensional signals (colourgrams) which keep spatial information and color information at the same time. This approach allows to analyze many images in a short time. The demand of such a limited computational effort promotes the implementation of automated systems.

Extraction of chemical, physical, rheological and sensory information from food images; Construction of predictive models for the rapid differentiation of the products in quality classes; Construction of predictive models to quantify different properties of the products, including defects; Ability to automate the control systems based on RGB images.

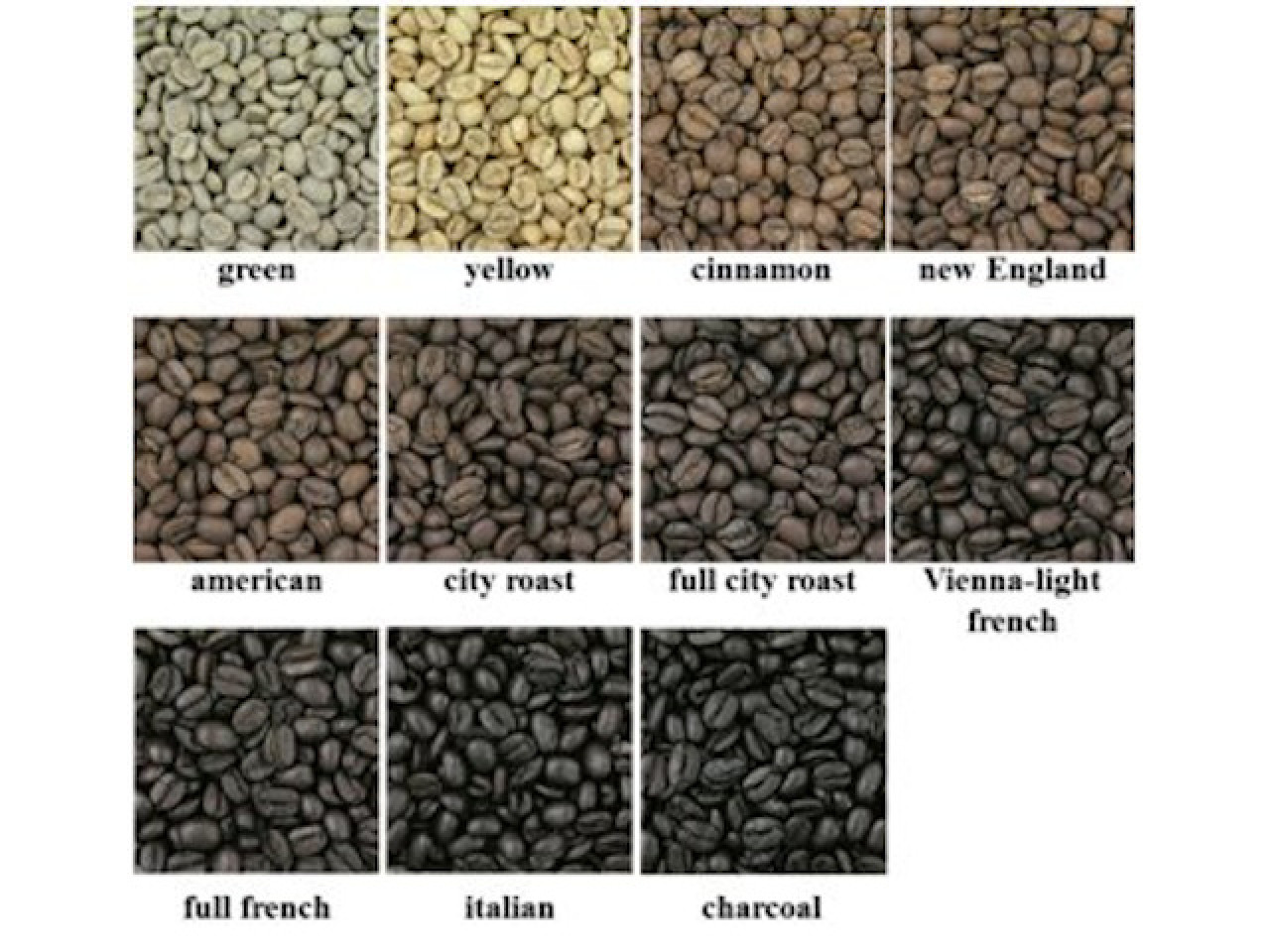

Coffee roasted at different roasting degrees

Coffee roasted at different roasting degrees

Measurement of the roasting degree of ground coffee

Each recipe has an expected color index, i.e., a color value that is expected for a specific blend of different coffees subjected to a given protocol of roasting. Compliance with the company specifications is satisfied when the value of the color index measured after grinding is in the range equal to the value of the expected color index ± 4 units. In this work, a quick and inexpensive system for color evaluation has been implemented. This system can be used by the company in a over-the-counter application which does not require dedicated tools or specialized personnel. The results obtained from the application of this approach to the samples of ground coffee were excellent: the error of the calibration model obtained is lower than the company tolerances and could be further lowered by implementing the model with new samples.

A leading company in coffee roasting

This approach for coffee quality control may undergo to the following future developments: extension of the application to the evaluation of other quality parameters, such as the degree of homogeneity; storing in electronic format of images and results for the construction of a database of historical data; possibility of implementing an automated on-line control system.

Acquisition and processing of the images

Acquisition and processing of the images