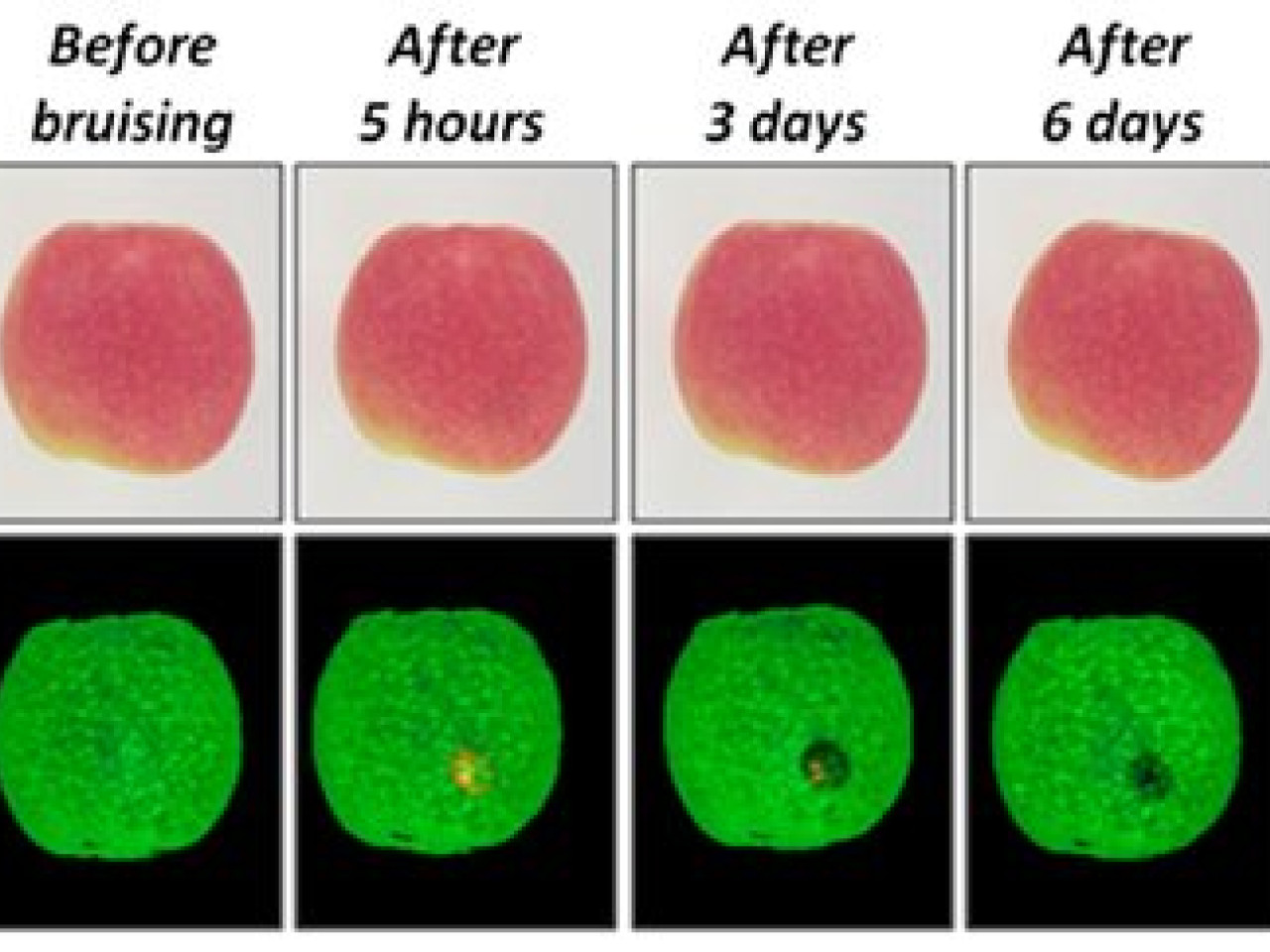

The hyperspectral images acquired in the near infrared (NIR) range combine the advantages of spectroscopy and imaging, enabling to obtain a sort of "chemical photography" of the sample in which the sample aspects hardly visible or not visible to the naked eye are highlighted. In this context, the CHIMSLAB research group of BIOGEST-SITEIA has already successfully implemented several studies, including: early identification of bruises in apples after different time intervals identification of the 'pale spots' defect in industrial buns varietal classification of green coffee samples differentiation of polymers for food packaging for the application in recycling plants

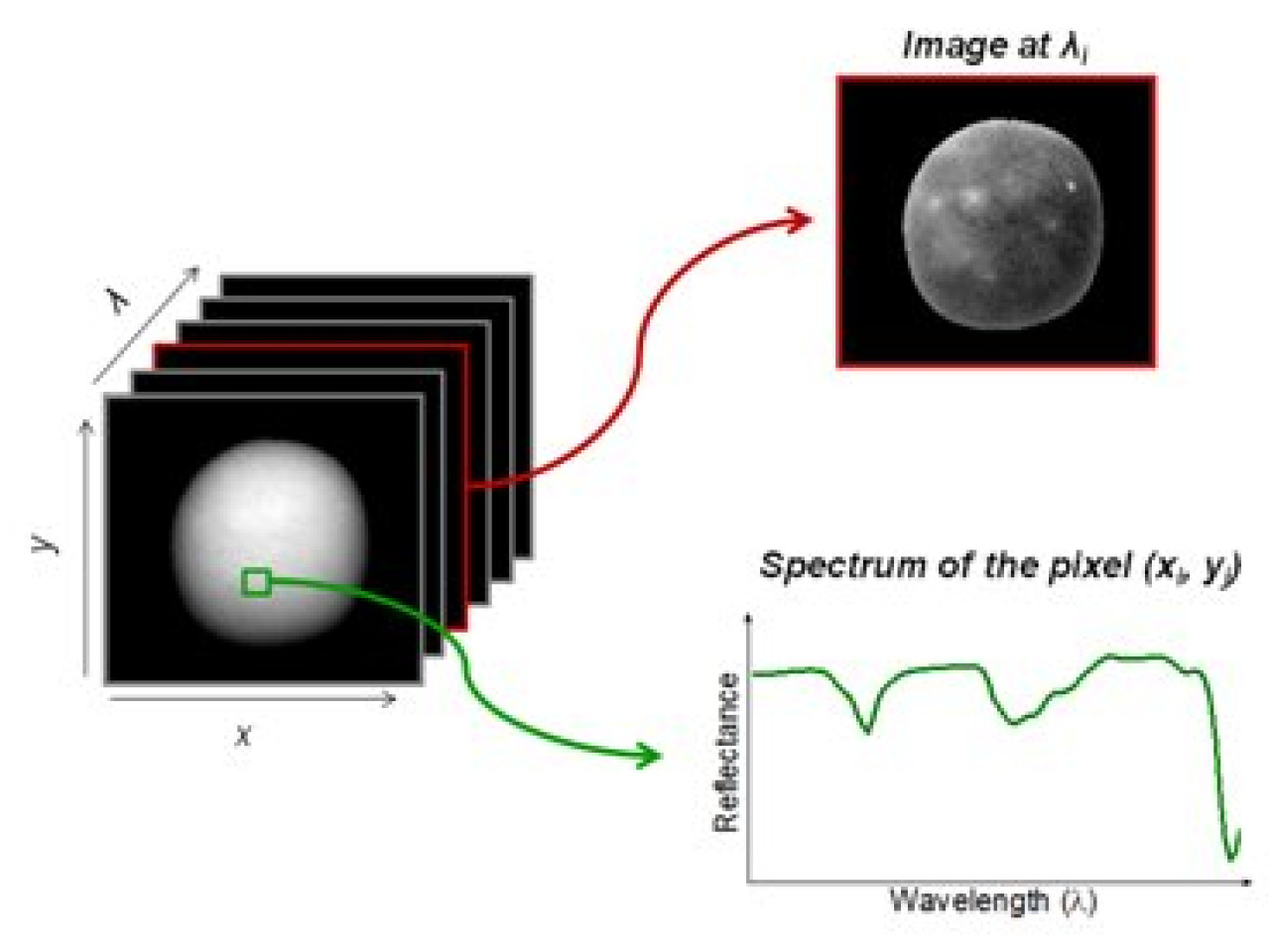

Schematic representation of a hyperspectral image structure

Schematic representation of a hyperspectral image structure

The hyperspectral imaging is a really interesting emerging technique because it is characterized by high performances in terms of time of analysis, cost, selectivity and invasiveness towards the sample. It allows to identify and locate, in a fast and reliable way, the presence of certain chemical or microbial species, as well as other adulterants or defects that may be present in the sample.

Applicable to different foods for: achievement of a "chemical photography" of the sample; rapid differentiation of the products in quality or defectiveness classes; simultaneous (non-invasive and non-destructive) determination of numerous constituents.

NIR imaging highlights aspects of the sample not visible to the naked eye (example: bruising)

NIR imaging highlights aspects of the sample not visible to the naked eye (example: bruising)

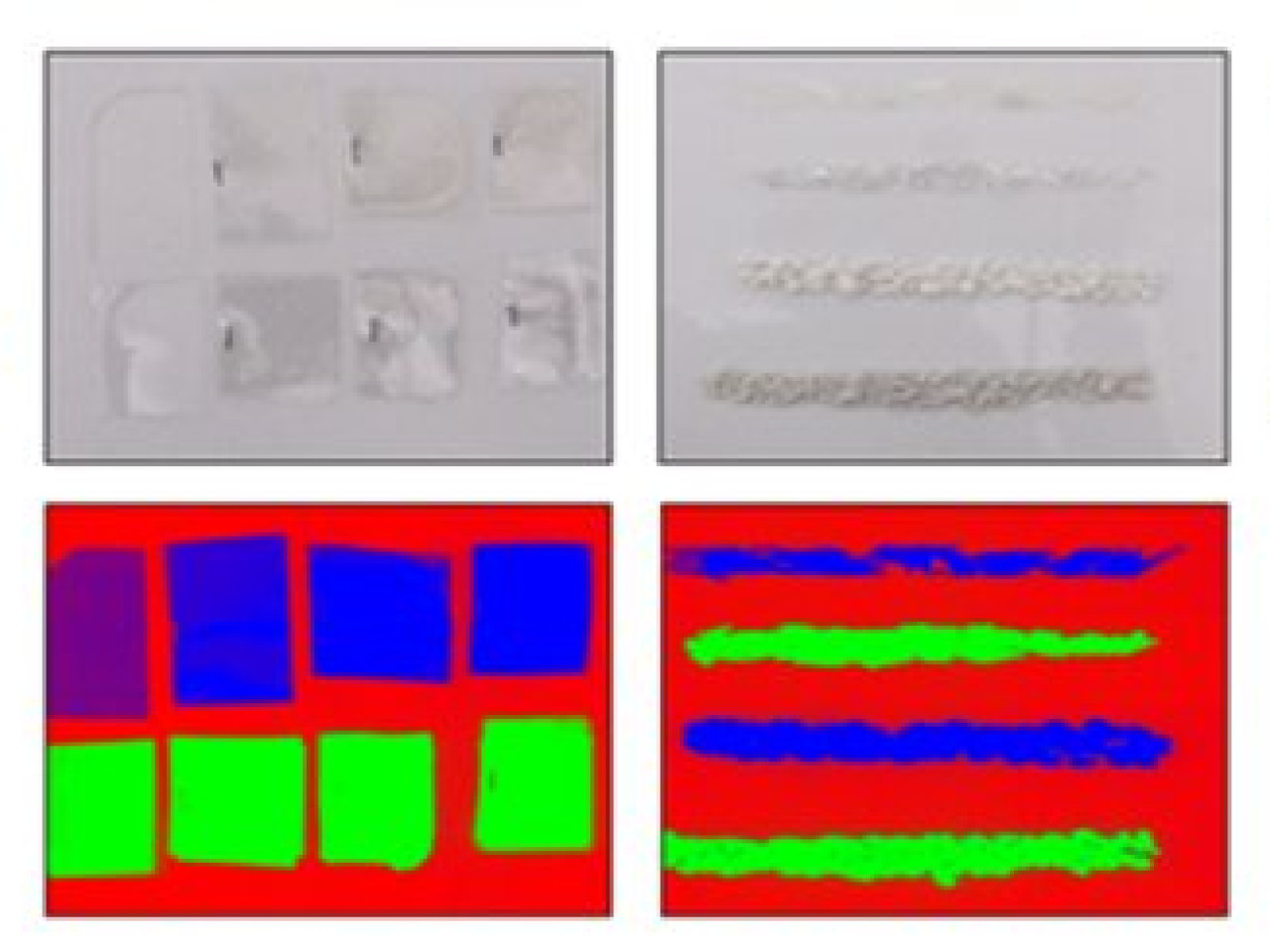

Differentiation of polymers for food packaging for the application in recycling plants

The biopolymer PLA is used in environmentally-friendly packaging, entirely made from corn or sugar cane, but it is similar for aspect and texture to common PET, with which can be confused. The potential contamination by PLA in the recycling flow of PET can have a negative impact on the physical properties of the recycled PET, making the material unusable. In this application, samples of PET and PLA were analyzed using the hyperspectral imaging, then the collected images were processed to obtain a mathematical model able to distinguish the two polymers. The model should be implemented in an automated sorting system to avoid PET contamination. The results showed that it is possible to distinguish between PET and PLA polymers using hyperspectral imaging in the NIR region. In particular, it was obtained a mathematical model to be used for predictive purposes. The development of high-performance software for the management of such large amounts of data is a further practical result of the work.

Producer of machines for the polymer sorting in recycling plants

The developed procedures can be used for quality control purposes and/or for the definition of a rationale of sorting in the recycling process. The models can be extended to the automated recognition of other types of polymeric materials.

Transparent polymers and their correct classification based on NIR hyperspectral images

Transparent polymers and their correct classification based on NIR hyperspectral images