This devices are miniaturized sensors able to provide extremely accurate pressure measurements. They are plane capacitors with parallel plates, whose capacitance has a non-linear dependence with the pressure. They can be implemented in applications that require pressure monitoring, such as weather stations, planes, factory plants and many others. This device was designed and realized by Istituto per la Microeletronica e Microsistemi (IMM), at CNR Research Area in Bologna.

Pressure capacitive micro sensors

Pressure capacitive micro sensors

Capacitive transduction can provide much higher resolution respect to those achievable with piezoresistive transduction, which is the most common transduction mechanism in pressure sensors. The very compact size of the device allows for an easy integration in system in which a minimal size is required.

Possible applications of a miniaturized pressure sensor are various, from weather monitoring instrumentation to factory plants, altitude sensing, flux sensing and gas leakages.

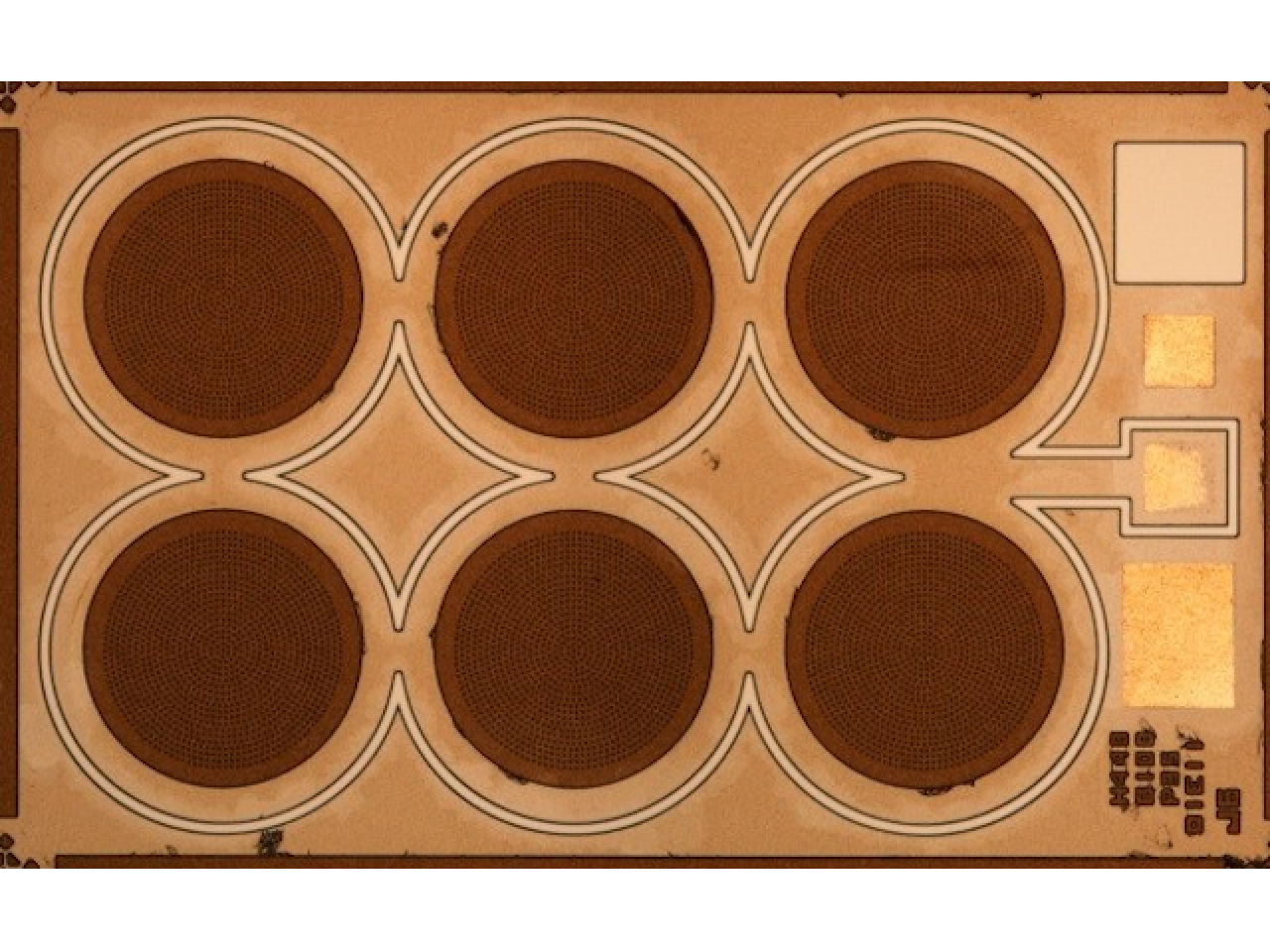

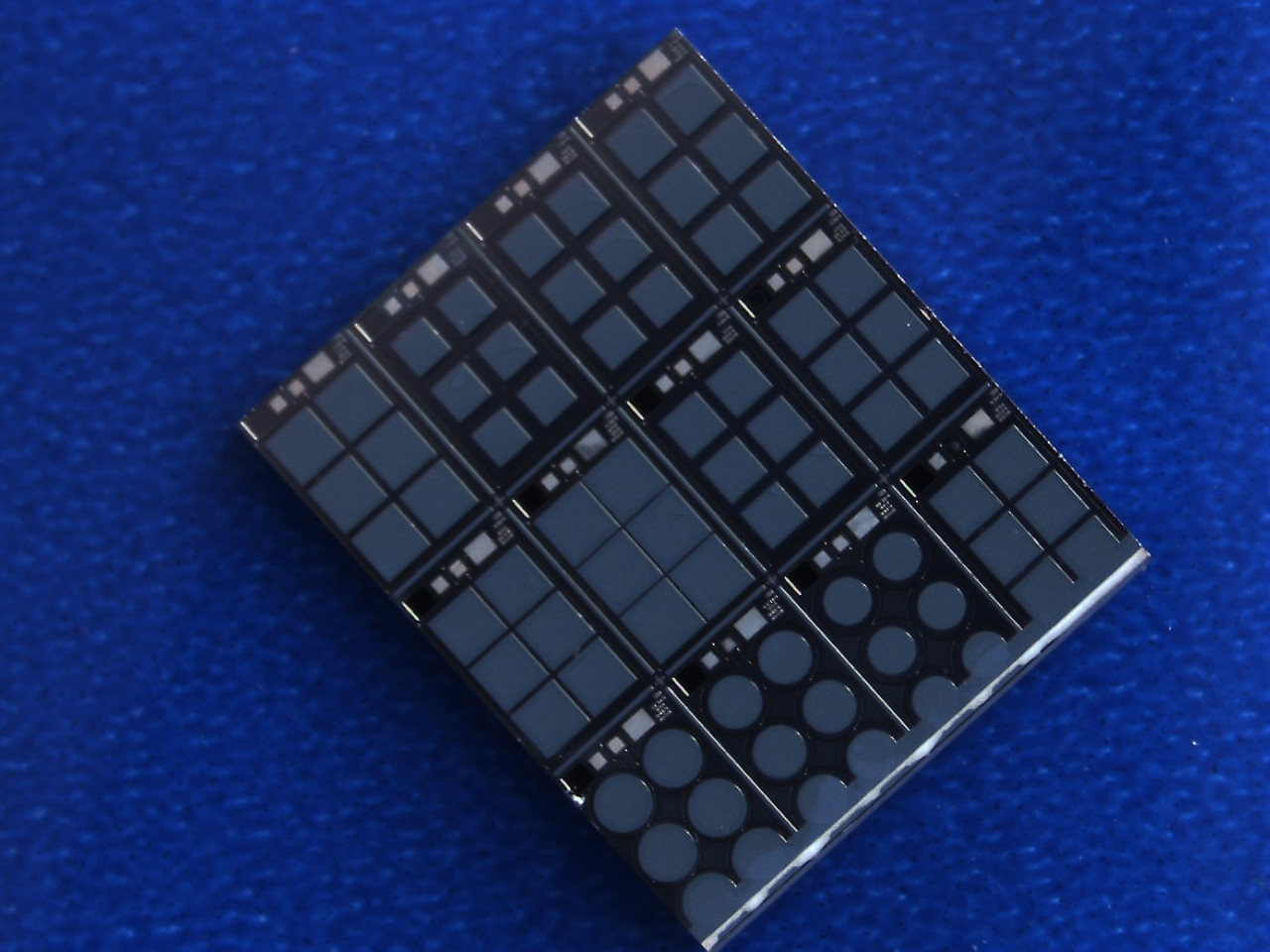

Picture of a chip with 18 pressure sensors with square and circular geometry, each one composed by 6 membranes.

Picture of a chip with 18 pressure sensors with square and circular geometry, each one composed by 6 membranes.

Catheter for endoscopic medical investigations, equipped with pressure measurement points

Here, the capacitive pressure sensors represent the core of a device for medical investigations, within a collaboration project with a company working in healthcare field. It is a catheter suitable for gastroenteric investigations, characterized by pressure measurement points regularly disposed along the device. A suitable design of the electronics can allow the user to ask a specific measurement point, obtaining a map of the pressure of the explored zone (trachea/esophagus). In this context, the developed technology allows to obtain highly detailed information on important parameters typical of breathing mechanics and of clinical relevance.

MEDICA S.p.A.

As a consequence of miniaturization, this kind of pressure sensors is particularly suitable for implementation in small layouts. This fact, in addition to the very high achievable precision of capacitive pressure sensors makes them ideal candidates for local measurements, in which variations among points physically very close to each other can be extremely small.

Core of the catheter prototype for gastroesophageal investigations.

Core of the catheter prototype for gastroesophageal investigations.