Geopolymers are synthetic inorganic polymers based on aluminosilicates or phosphates and chemically bonded at T <300 ° C. This technology enables the production of materials with properties of certain ceramic materials with the same approach of plastics, in view of the removal of heavy equipment and high temperature from industrial ceramic plants. Indeed the geopolymer artifacts can be produced for molding and without the aid of further finishing. Geopolymers are eco-friendly and sustainable. Geopolymers are always composites: the nanostructured geopolymer matrix acts as the glue for inert fillers, that functionalize or reinforce the material. Geopolymers are used in many industries, such as transport, construction and infrastructure, metallurgy, waste treatment, restoration, art, biomaterials, chemistry etc.

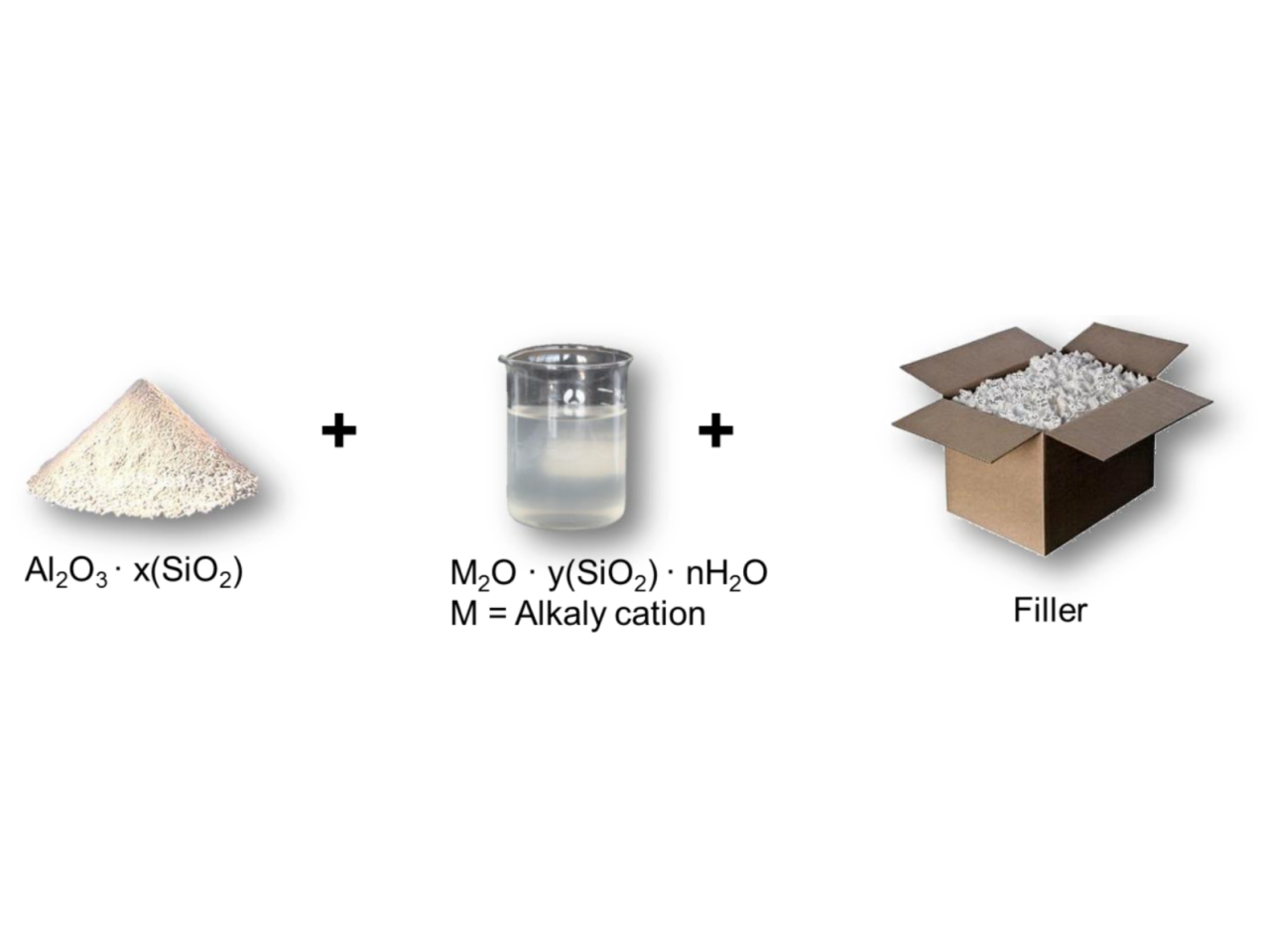

Fig. 1 Geopolymer formulation

Fig. 1 Geopolymer formulation

These are materials with ceramic properties (e.g. high refractory) without the aid of consolidation technologies at high temperature. The geopolymerization is eco-friendly: it takes place in water. The process is versatile and suitable for complex shaping methods, similar to those of the polymer industry. Also direct and indirect foaming techniques allow to realize hierarchical porous architectures. The geopolymer matrix is nanostructured and compatible with fillers of different nature, that functionalize the composite material and make it applicable in various fields.

Geopolymers are non-combustible, they don’t evolve gases or fumes, they are not toxic and they don’t "explode." ISTEC therefore produces geopolymers for structural and thermo-mechanical applications: refractory coatings, heat exchangers, composites for thermal and acoustic insulation, resistance to fire (MI2014U000387 patent) and thermal barriers. Within the project POR-FESR "EEE-CFCC" thermo-structural molds for complex shapes and porous insulating are going to be realized. Furthermore, geopolymers are also proposed for new fields such as catalysis, filtration, gas sorbents, wicking

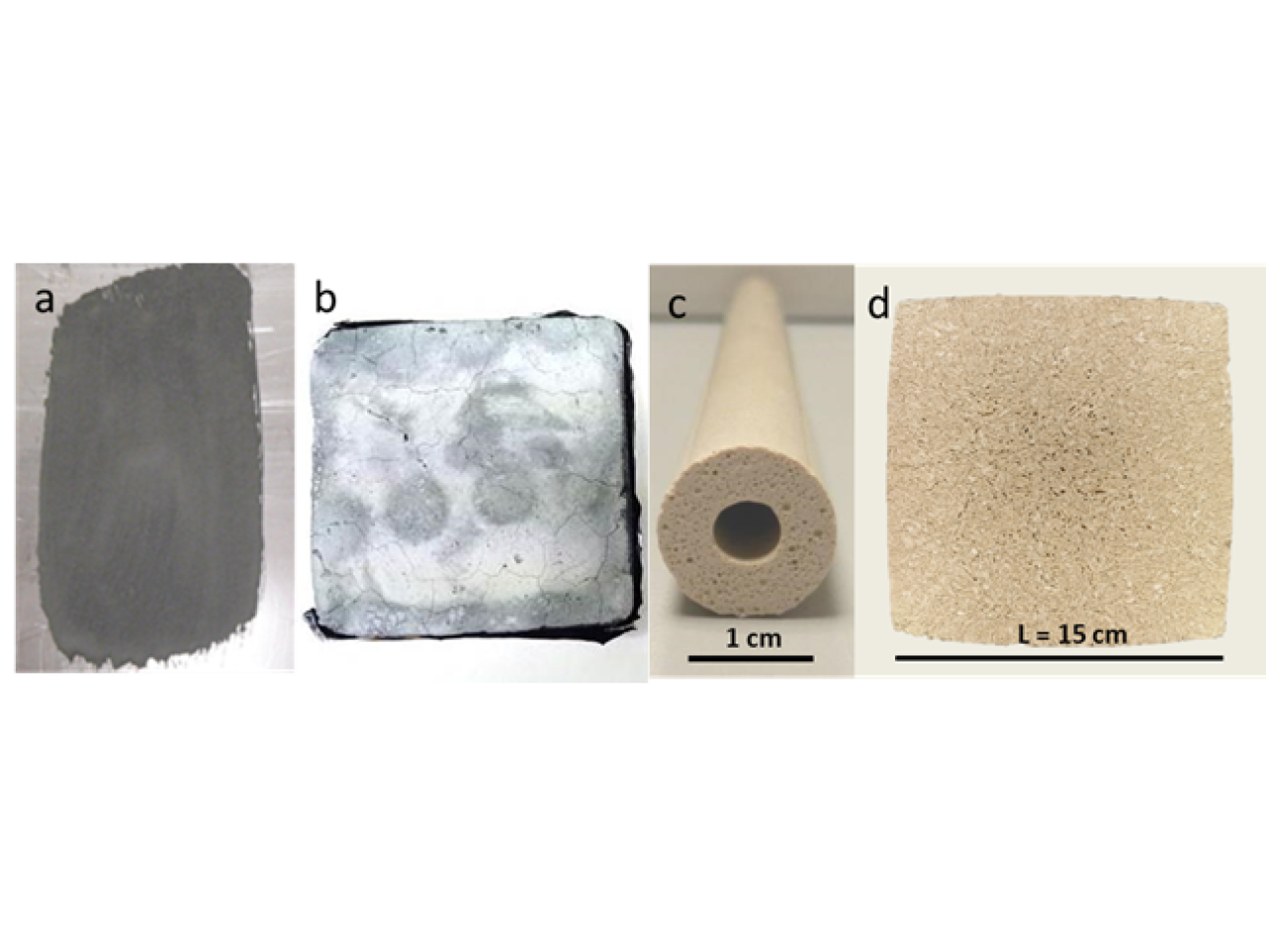

Fig. 2 Examples of products: SiC-based paint with geopolymer binder (a); geopolymer-wool composite panel (b); porous wick (c) and panel with unidirectional porosity (d).

Fig. 2 Examples of products: SiC-based paint with geopolymer binder (a); geopolymer-wool composite panel (b); porous wick (c) and panel with unidirectional porosity (d).

Fiber-reinforced thermal barriers

The application concerns aeronautics and in particular thermal barriers of fiber-reinforced material. The inorganic fiber-reinforced materials, therefore heat-resistant, are currently produced with time-consuming technologies. The use of chemical bonded ceramics (such as geopolymers) greatly reduces the time and temperatures of production. ISTEC has designed ad hoc formulations for completely inorganic resins which are suited to technologies, such as vacuum bagging, commonly used for fiber-reinforced polymers. It is possible then the production of complex shape prototypes with a ceramic-based matrices, but using typical production techniques of conventional composites (i.e. autoclave), thus resulting in simplification of the production process and consequent reduction of costs.

Air Force Service SpA

ISTEC activities took place under an industrial research agreement thanks to which Air Force Service was able to activate a new production line and draw validation protocols to enter the market. The current TRL is 8.

Fig. 3 complex shape rototypes made by the Company: exhaust pipe (a); thermal barrier (b, c); engine nacelle (d, e).

Fig. 3 complex shape rototypes made by the Company: exhaust pipe (a); thermal barrier (b, c); engine nacelle (d, e).