Patented system for intelligent management and automated control of wastewater treatment plants (WWTPs). The system uses robust and cheap probes to measure indirect signals, such as pH and redox potential (ORP), in order to reduce the construction costs and make the installation economically sustainable even for medium-small plants, until 20,000 PE (Population Equivalent), usually unequipped with control systems, despite representing more than 80% of the total number of WWTPs in Italy. The system increases: 1. the energy efficiency of the aeration system, responsible on average for about 60% of the energy consumption of the wastewater treatment plants, also greatly affecting the overall management costs; 2. the efficiency of the pollutants removal process, by real-time monitoring of the process conditions and operative state of the plant, ensuring low total nitrogen concentration at the discharge.

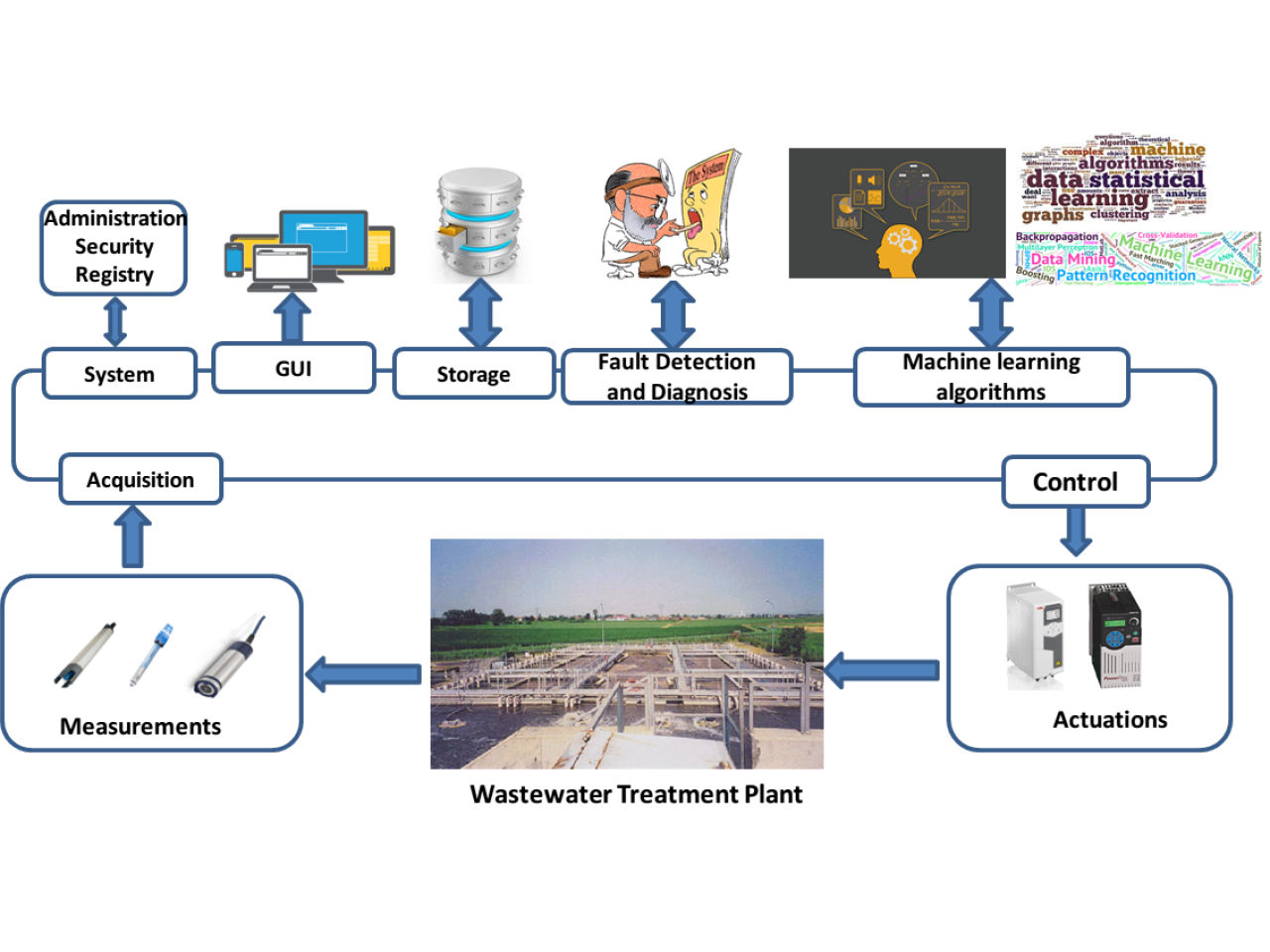

Logical block diagram of the control system

Logical block diagram of the control system

In Italy, medium-small WWTPs (up to 20,000 PE) represent about 90% of the total plants and their specific cost (€ / m3) is higher than that one of large plants (over 100,000 PE), despite this they often lack instruments or control systems due to their high cost. The proposed system has been designed to reduce construction costs, while maintaining high performance and thus allowing installation even in small-medium plants.

The invention can be used by water utilities to automatically control and manage wastewater treatment plants. In Emilia-Romagna, the plants on which the system could be applied are 243 (68 with size between 10,000 and 100,000 PE plus 175 between 2,000 and 10,000 PE). Considering the plants managed by HERA, potentially around 120 can be controlled with this system (38 with size between 10000 and 100,000 PE, plus 82 between 2,000 and 10,000 PE). The same assessments can be extended to all Italian water utilities.

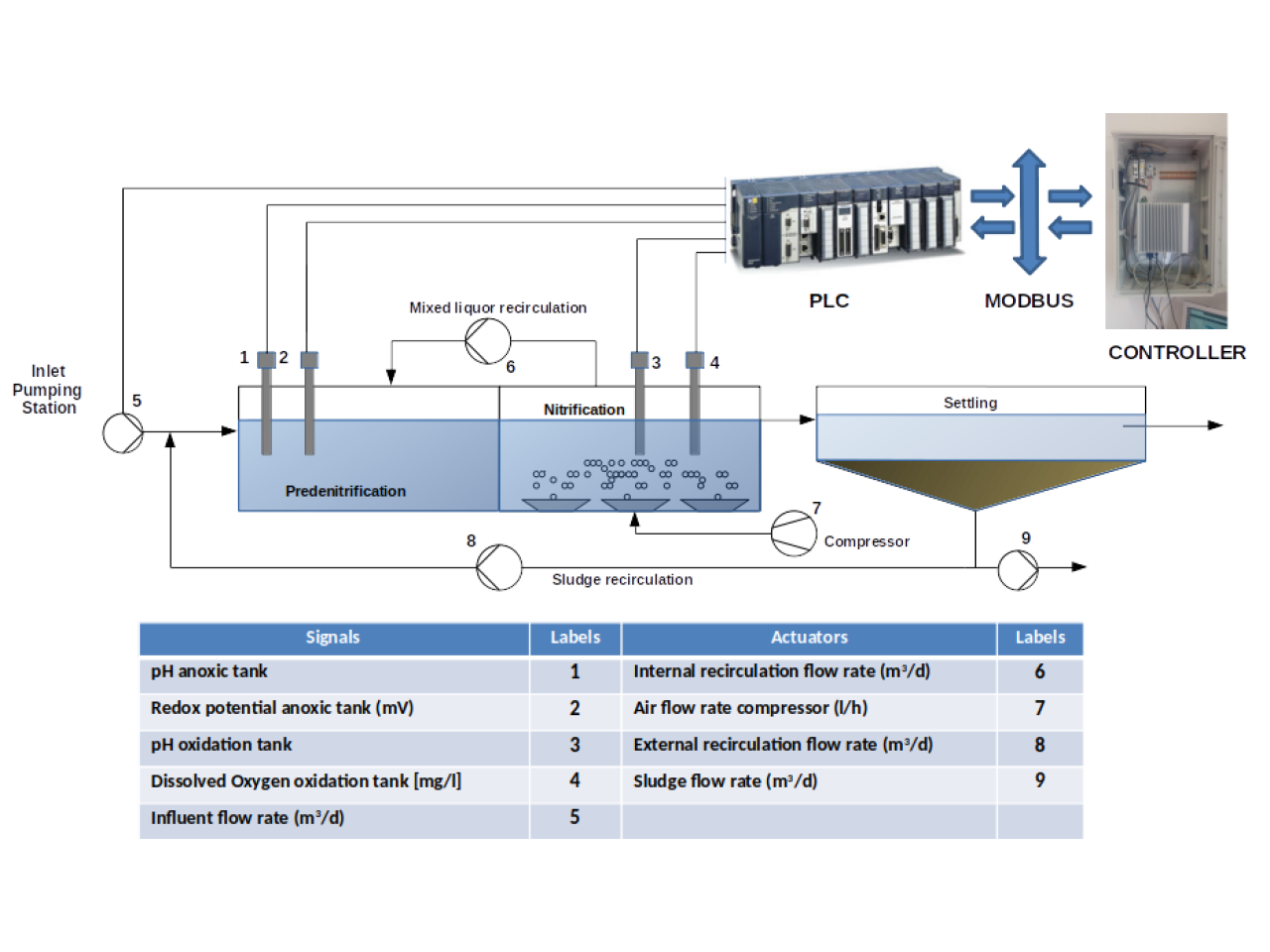

Layout of the controller installed on the plant

Layout of the controller installed on the plant

Installation and testing activity of the controller on the municipal sewage treatment plant of Granarolo dell’Emilia (Bo), managed by HERA SpA.

Assembling the system required: 1. Installation of sensors for measuring pH and ORP signals in anoxic tank and pH and DO signals in oxidation tank. 2. Installation of variable-frequency drives in order to change the speed of the blower and the circulation pump of the aerated mixture. 3. Installation of the industrial PC where the software implementing the controller is installed 4. Implementation of communication between the controller and the WWTP's PLC. The controller was started for a first test and validation data acquisition campaign. These data have been used to tune the model of the system, simulating the outputs as the operating conditions change. In order to assess energy efficiency, the monthly consumption due to the blower before and after the controller starts operating will be compared, both measured with the same energy analyser. After one month of operation, energy savings of over 30% can be estimated. Given a power consumption of 9.1 kW at full load at f = 50 Hz, with a maximum energy consumed of 79.8 MWh / year, savings of about 24 MWh / year can be achieved. At an average price of 0.15 € / KWh, over 3600 € / year can be saved for this type of compressors, small in size and of the IE3 type, the most efficient on the market.

HERA SpA

Industrial invention patent no. 102015000084042 "GROUP FOR THE AUTOMATED MANAGEMENT OF PLANTS FOR THE BIOLOGICAL TREATMENT OF WASTEWATER", valid in Italy on 6/6/2018. The PCT extension is being approved. The experimentation currently underway will shortly allow us to present the first consolidated results to start industrial partnerships.

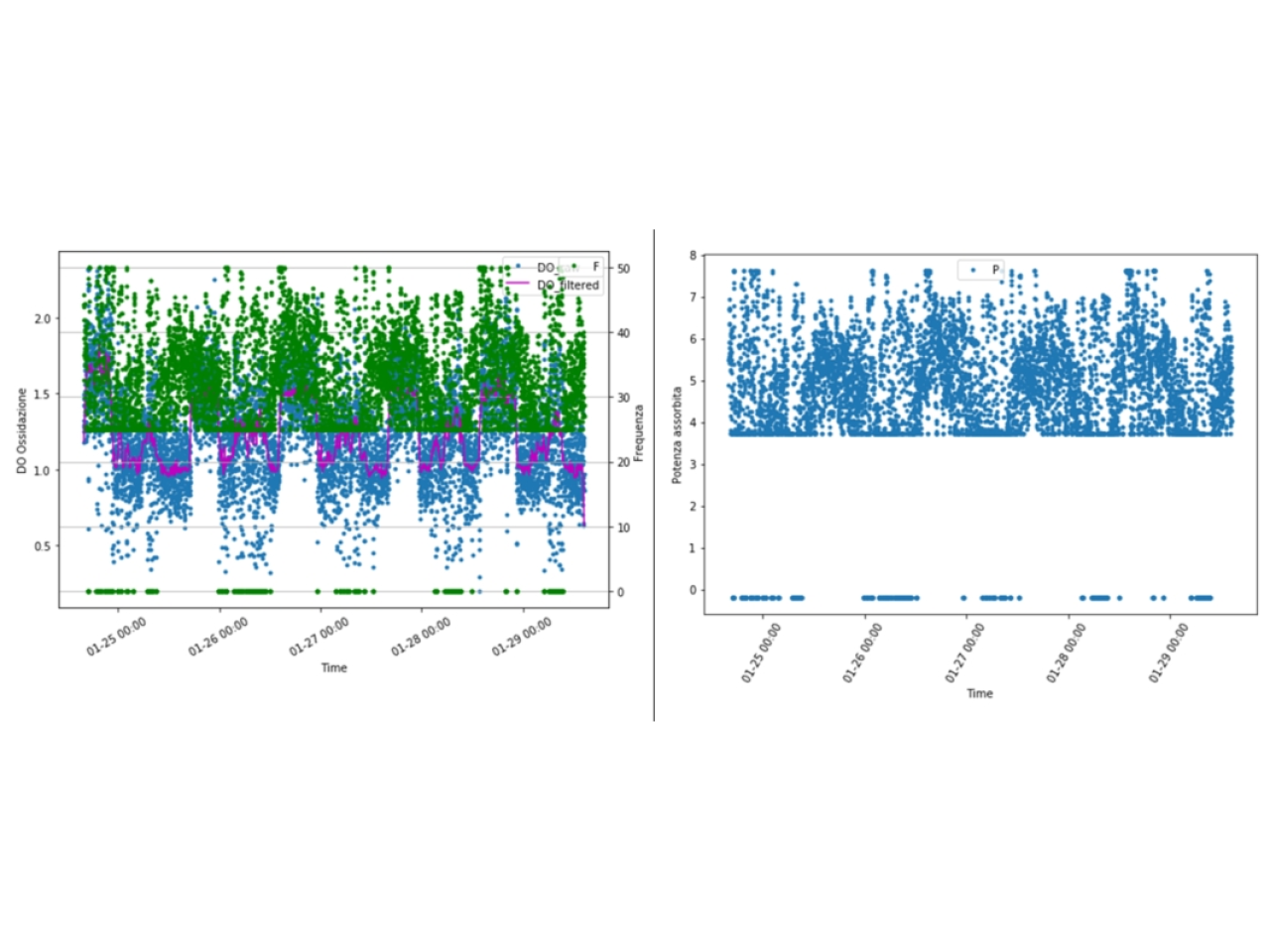

Example of dissolved oxygen and inverter frequency (left) and absorbed power (right) trend for 5 consecutive days. Total consumable energy = 886.5 KWh Actual energy consumed= 532.9 KWh

Example of dissolved oxygen and inverter frequency (left) and absorbed power (right) trend for 5 consecutive days. Total consumable energy = 886.5 KWh Actual energy consumed= 532.9 KWh