The growing need for energy and raw material savings and the desire to increase the lifetime of mechanical systems stimulate tribology applied research, aimed to the development of anti-friction and anti-wear technological solutions. Mainly, in some sectors ruled by strict regulations regarding health and environment protection (e.g.: food industry, biomedical) and/or characterized by critical operative conditions (i.e.: aerospace, vacuum industry) the introduction of strategies for liquid lubricant replacement is mandatory. SUP&RMAN Lab. activities are framed into this context: study, growth and characterization of functionalizing coatings, properly optimized to guarantee both wear resistance and self-lubricating performances.

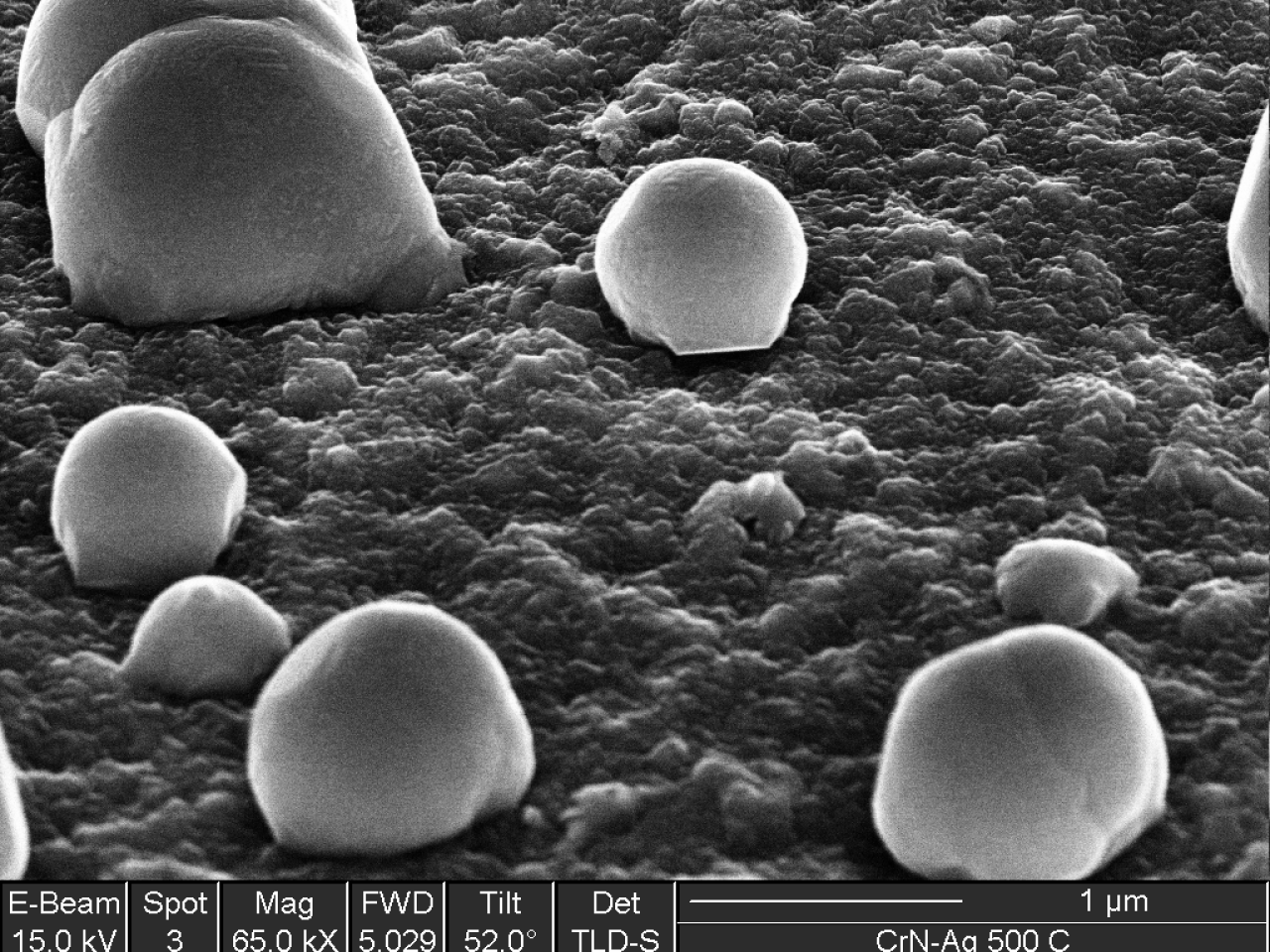

SEM image (magnification: 65000 x): surface of a nanostructured CrN-Ag ternary coating

SEM image (magnification: 65000 x): surface of a nanostructured CrN-Ag ternary coating

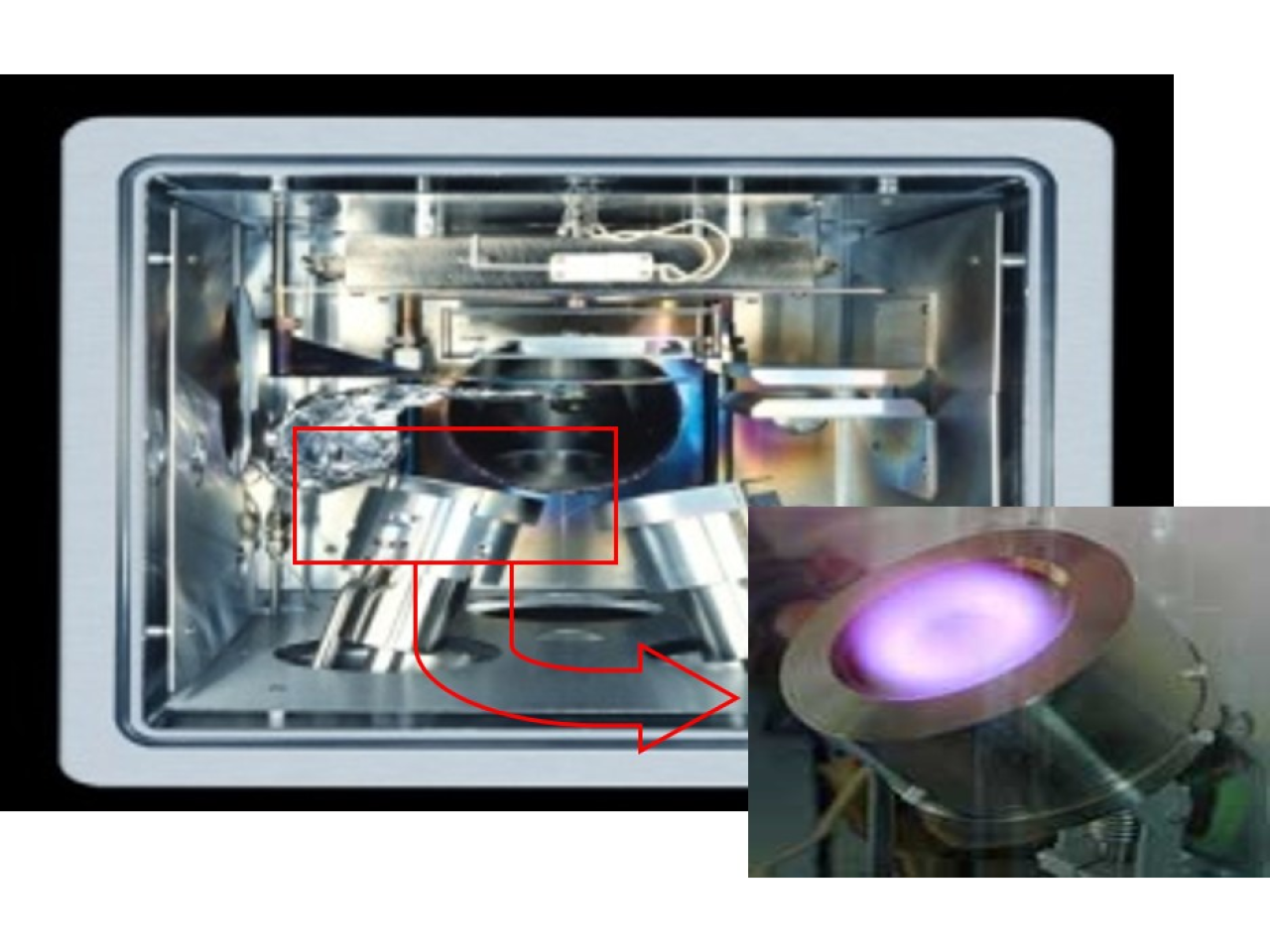

Liquid lubricant replacement is the fundamental key factor in term of innovativeness. The request of high strategic impact is filled by the combination of specific surface functionalities through high-tech approaches (material mixing, doping, micro-structuring). Other important elements that will reinforce the competitiveness are: the high performance factor provided by the couplings of crucial properties, usually conflicting, such as self-lubrication and wear resistance; the added value provided by the development of composite new materials, where the micro-/nano-scaled additives are able to auto-organize themselves so as to induce integrated benefits at the macro-scale; the added merit ensured by the use of state-of-the-art coating technologies (i.e.: PVD MS, Physical Vapor Deposition Magnetron Sputtering) much more eco-friendly than galvanic processes.

Hybrid self-lubricant coatings deserve to be considered as good candidates for the solving of mating contact issues that affects different industrial sectors. A brief list: automotive, aerospace, oleodynamics, gear, precision mechanics, tools manufacturing, vacuum industry, decorative, innovative material for buildings, packaging, biomedical. Among all these above-mentioned contexts, tribological surface performances play a fundamental role in terms of functionality, durability, and thus market appealing of commercial items.

Equipped chamber for PVD Magnetron Sputtering deposition: external view

Equipped chamber for PVD Magnetron Sputtering deposition: external view

Critical mating coupling in gear systems

The successful goal was the optimization of a thin-film PVD MS growth recipe of a hybrid ternary coating (hard base: CrN; self-lubricant additive: Ag). The final step has been the application of such coating to a case study: a low power gear box, forced to high temperature range during working cycles (up to 600°C). Performance tests show a consistent increase of the lifetime of mating contacts under poor oil lubrication regimes condition and an appreciable decrease of acoustic emissions. The main conclusions is the validation of the expected powerful properties induced by the Ag-additive: good self-lubrication and high mobility through CrN-matrix furtherly accentuated by operative condition (high temperature). These effects improve tribological properties of such mating contacts involved in mechanical transmission. Thus, gear box operativeness improves in terms of: increase of working cycles and reduction of noise under a less use of fluid lubricant.

End user: Italian enterprise; sector: Mechanics. Scientific partnership: Consiglio Nazionale delle Ricerche (CNR), Istituto NANO S3, Modena, ItaliaFraunhofer Institute for Mechanics Materials, MikroTribologie CentrumFreiburg, Germania. AIN, Center of Advanced Surface Engineering, Spagna

The results of the present project have enriched the know-how of the end-user project partner, which R&D strategies are now oriented to evaluate the application of such coatings to other high-added value own products.

Equipped chamber for PVD Magnetron Sputtering deposition: internal view

Equipped chamber for PVD Magnetron Sputtering deposition: internal view