Innovative concrete elements realized by dry pressing method, constituted by secondary raw materials up to 80% by weight. The elements, with dimensions of about 250 mm x 250 mm, are suitable for applications in traditional walls or ventilated facades as well. The product ensures good mechanical characteristics with high durability degree and significant properties of thermal isolation if compared to elements with similar composition and density. The high amount of secondary raw materials provides high environmental compatibility and sustainability for industrial applications.

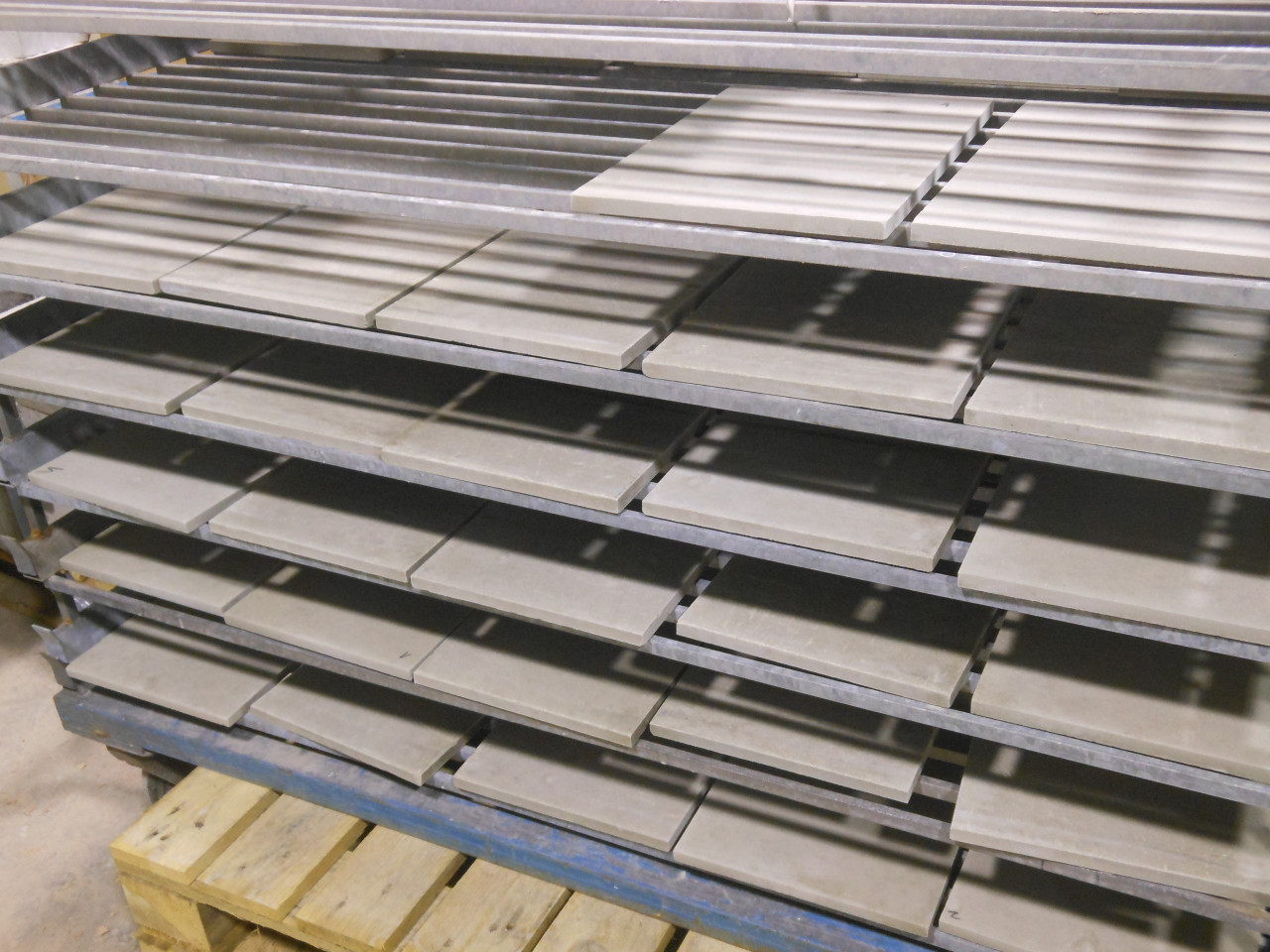

Eco-tiles specimens realized on semi-industrial scale by dry pressing method.

Eco-tiles specimens realized on semi-industrial scale by dry pressing method.

The use of secondary raw materials represents an innovation element, connected to the environmental sustainability of the product itself. This allows to obtain products with high performances in terms of mechanical characteristics, durability and thermal insulation. Furthermore, it contributes to obtain credits for LEED certification, in particular MRc4 (amount of recycling) of protocol LEED 2009 and MRc2 (environmental product declarations), MRc3 (supplying of raw materials), MRc4 (material’s ingredient) and MRc1 (reduction of the life cycle impact of building) of Protocol LEED v4.

The product can be applied as facing material for ventilated facades and has significant environmental benefits in terms of overall sustainability of projects where it is expected his application. Alternatively, it could be used also for traditional walls, with appropriate cementitious adhesives to ensure adhesion to the substrate.

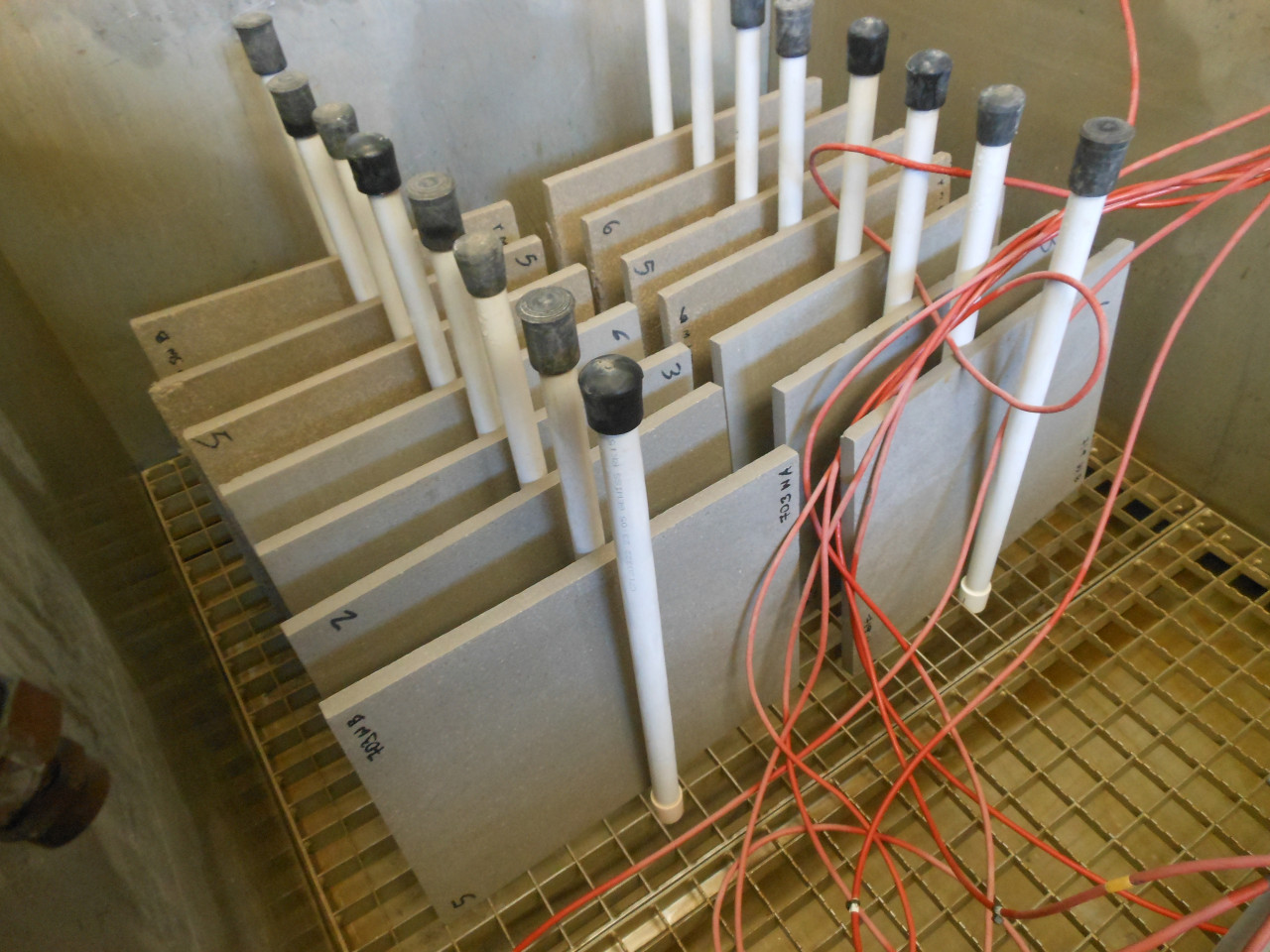

Specimens of eco-tiles in testing-phase, positioned into the climate chamber.

Specimens of eco-tiles in testing-phase, positioned into the climate chamber.

Standard ventilated facade or external covering for existent building

The material has been developed and tested according to EU regulations for this kind of products. The following steps of study will consider the engineering of fixing systems for installation of product in relevant environment, or rather for applications in real wall systems. Innovative Eco-tiles according to EU standards concerning the sphere of Concrete Slabs and Ceramic Tiles. Products with high performances in terms of thermal hygrometric-charcteristics (reduced thermal conductivity of mixture) and durability (high resistance to freeze-thaw cycles and to environmental stresses in case of de-icing salts).

Officina dell'Ambiente S.p.A., Lomello - Pavia SACMI Imola S.C., Imola - Bologna

The developed product represents a sustainable solution with high performance for requalification of existing buildings walls (as ventilated facades or traditional). The system was been developed and realized aiming at the Italian and European market, starting from agreements with multinational companies in construction sector (building envelope).

Test of environmental stresses to predict the on-field behaviour.

Test of environmental stresses to predict the on-field behaviour.