Magnetic refrigeration, based on the magnetocaloric effect, is a new cooling technology alternative to traditional gas compression. It promises reduced environmental impact, higher energy efficiency, lower noise, and vibrations. This technology exploits the temperature variation of special alloys, so-called magnetocaloric materials, induced by the cyclic variation of magnetic fields, replacing in this way the gas compression cycles. The present-day refrigerant fluids are replaced by non-toxic, easy to recycle, solid magnetic materials; the heat exchange between the magnetocaloric material and the thermal load is mediated by safe, non-hazardous liquids such as water. This prototype has been built for studying and validating the technology.

This prototype displays a new way to cool which is not yet present on the market. The working principle is based on eco-compatible aqueous solutions and solid materials (magnetocaloric, permanent magnets), which are easy to contain and reduce the risks of dispersion in the environment

Cooling machines operating under temperature span demands: e.g. wine coolers, air coolers, refrigerators for some bio-medical applications. In principle, via further optimization and by constructing multi-stage devices, this technology is compatible also with very high-temperature spans (e.g. freezers, or even air liquifiers)

Cooling application

The prototype has been tested as a cooler, with the cold exchanger inside an insulated chamber. At the time of writing (one regenerator operational), a thermal jump of 8 degrees with no thermal load has been achieved. The measures have been performed in a realistic environment (the hot exchanger being at ambient temperature, not controlled). By optimizing the functional parameters a thermal jump around 20-30 °C appears feasible. The nominal thermal power, estimated on the thermal mass of the magnetocaloric regenerator, is in the range 7.5 – 150 Watts depending on the operating frequency (range 3-60 rpm).

MIST-ER MUSP CIRI EA CIDEA SPIN Jonix MBN nanomaterialia

In the future, the system will be tested to find the best working point of the complete configuration (4 regenerators). Multistage operations to get elevated temperature spans will be explored by replacing part of the magnetocaloric elements with others having graded working points. We will look for industrial partners interested in specific applications, e.g. wine coolers, bio-med refrigerators.

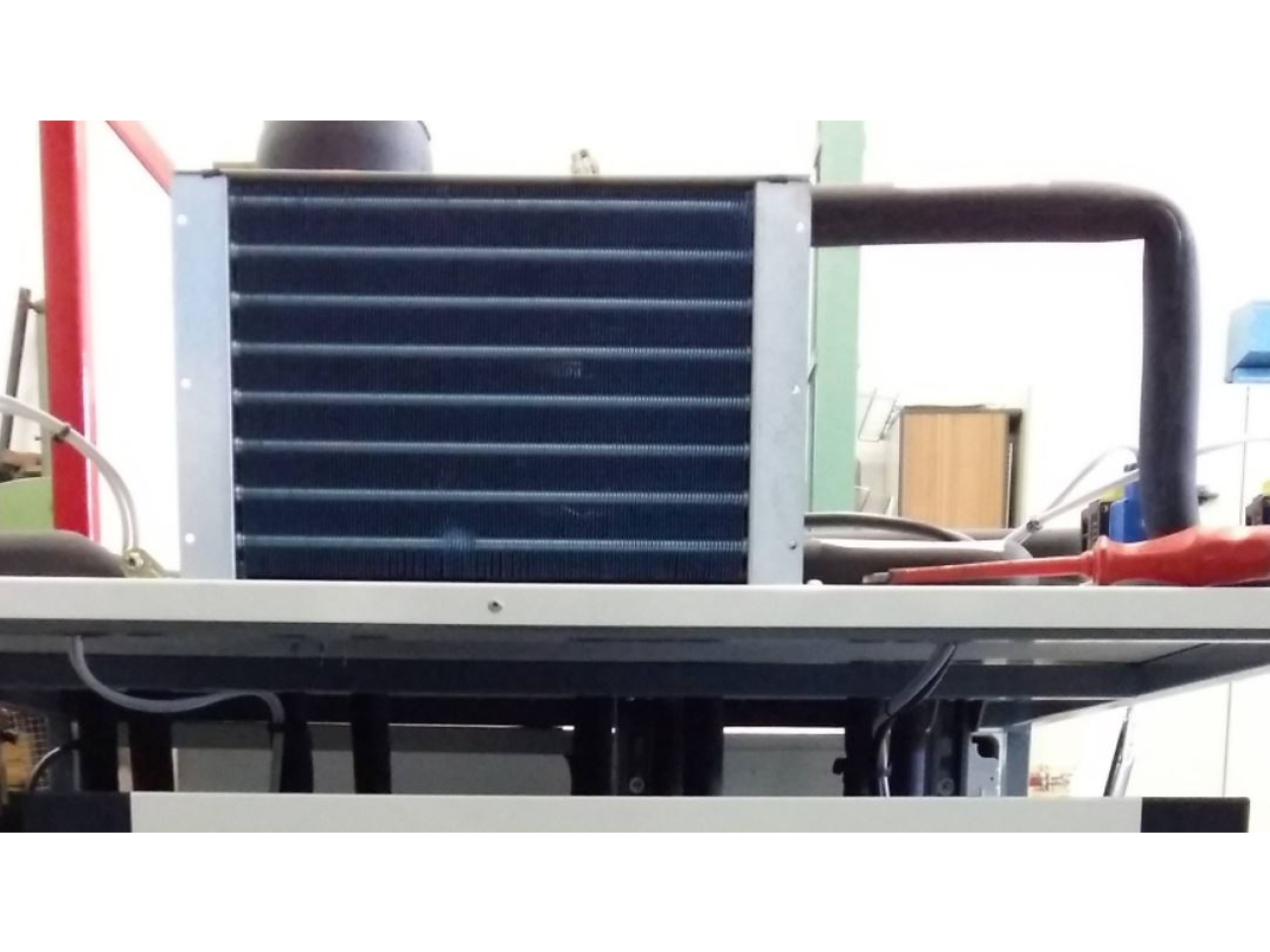

A detail of the heat exchangers: hot (top) and cold inside the insulated chamber (bottom)

A detail of the heat exchangers: hot (top) and cold inside the insulated chamber (bottom)