Graphene is currently one of the most extensively studied materials in the world, both at scientific and industrial level. It consists of microscopic sheets of carbon atoms, having the thickness of a single atom and a lateral size which may reach several tens of microns. Since its discovery in 2004, graphene has showed exceptional properties from various points of view: extremely high mobility of electric charge, high mechanical strength, excellent thermal conductivity, high surface area and it is impervious to all common gases. In recent years the number of scientific publications and patents on graphene has grown exponentially. A number of research centres and companies are investing energy and resources to study the use of graphene derivatives in electrically and thermally conductive composites, batteries, transparent electrodes, lubricants, sensors, protective coatings, inks, varnishes, etc.

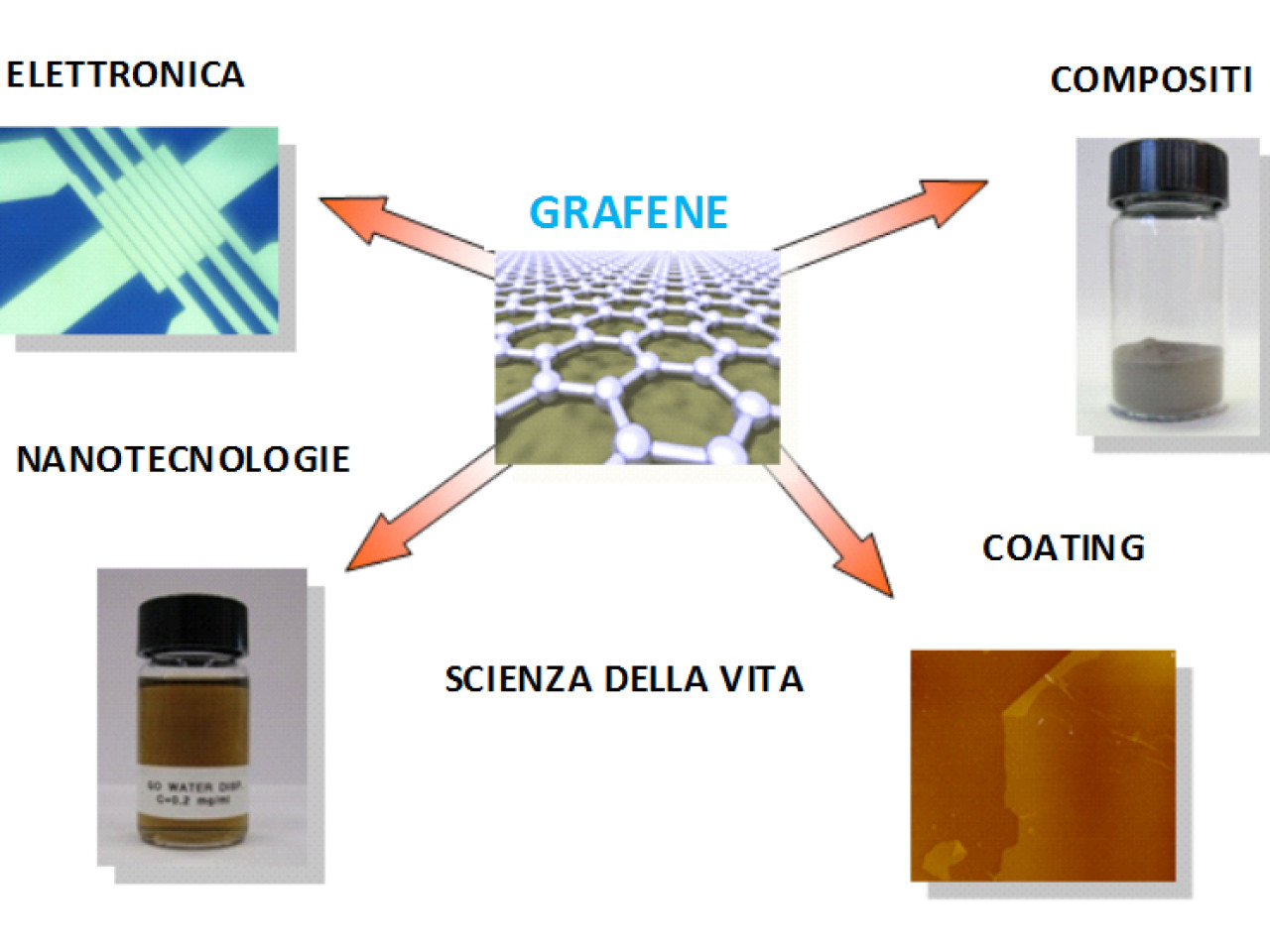

Some areas of interest of graphene derivatives

Some areas of interest of graphene derivatives

Thickness being equal, graphene is 300 times more resistant, and 5 times harder than steel, it has electrical conductivity of 6000 S/cm and thermal conductivity of 5000 Wm-1•K-1 (higher than copper). Furthermore, graphene features high surface area ≈ 2600m2/g.

Electrically and thermally conductive materials, gas-barrier, lubricants, conductive inks, flame retardants, antistatic, protective coatings, plastics, energy, catalysts, flexible electronics, sensors, composites, transparent electrodes, etc.

Some graphene derivatives produced at the Mister Laboratory

Some graphene derivatives produced at the Mister Laboratory

Production and development of new graphene-filled polymeric products

Emilia-Romagna has a high number of companies operating in the field of engineering, with well-known industrial excellence worldwide. To maintain this excellence and tackle the challenge of non-EU competitors, who often even significantly lower production costs, Emilia-Romagna companies are required to develop new high technology products in the polymer and engineering sector, resulting in hitherto impossible applications for these materials. Graphene is a multi-functional reinforcement which is able to improve at low concentrations the electrical, thermal, mechanical and gas barrier properties in polymers and may therefore be used as an additive to develop new materials and products in the industrial sector. The MIST E-R Laboratory, jointly with three Emilia-Romagna companies, is dealing with developing the productive processes involved in obtaining graphene-filled polymer composites. The aim of this project is to implement an actual production chain of companies for the production and characterisation of these new materials. A number of prototypes graphene derivative-filled polymers have been produced

GHEPI S.r.l. NEVICOLOR S.p.A. PENTACHEM s.r.l. Organic Synthesis and Photoreactivity Institute of CNR

Using graphene may support a quantum leap in quality in a number of application sectors such as automotive, aerospace, energy, etc., giving a clear competitive advantage to the first companies to develop its use on an industrial scale.

Some prototypes produced in the project

Some prototypes produced in the project