The development of customised test benches for R&D laboratories addresses the need by Businesses to reduce the time for new products' development and improvement of existing ones. To this end it is essential to have tools with a user-friendly interface designed according to the specifications of the very laboratory technicians who use them. The most suitable sensors to measuring the mechanical and thermodynamic values of concern are therefore selected based on users' requests, to then produce the entire measurement chain required for data acquisition. Unlike standard test benches, for instance devoted to production quality control, test benches produced for research and development laboratories must be adapted to the most varied test requirements. For this reason the flexibility of use of these benches is a fundamental feature to be able to assure a valid analysis tool.

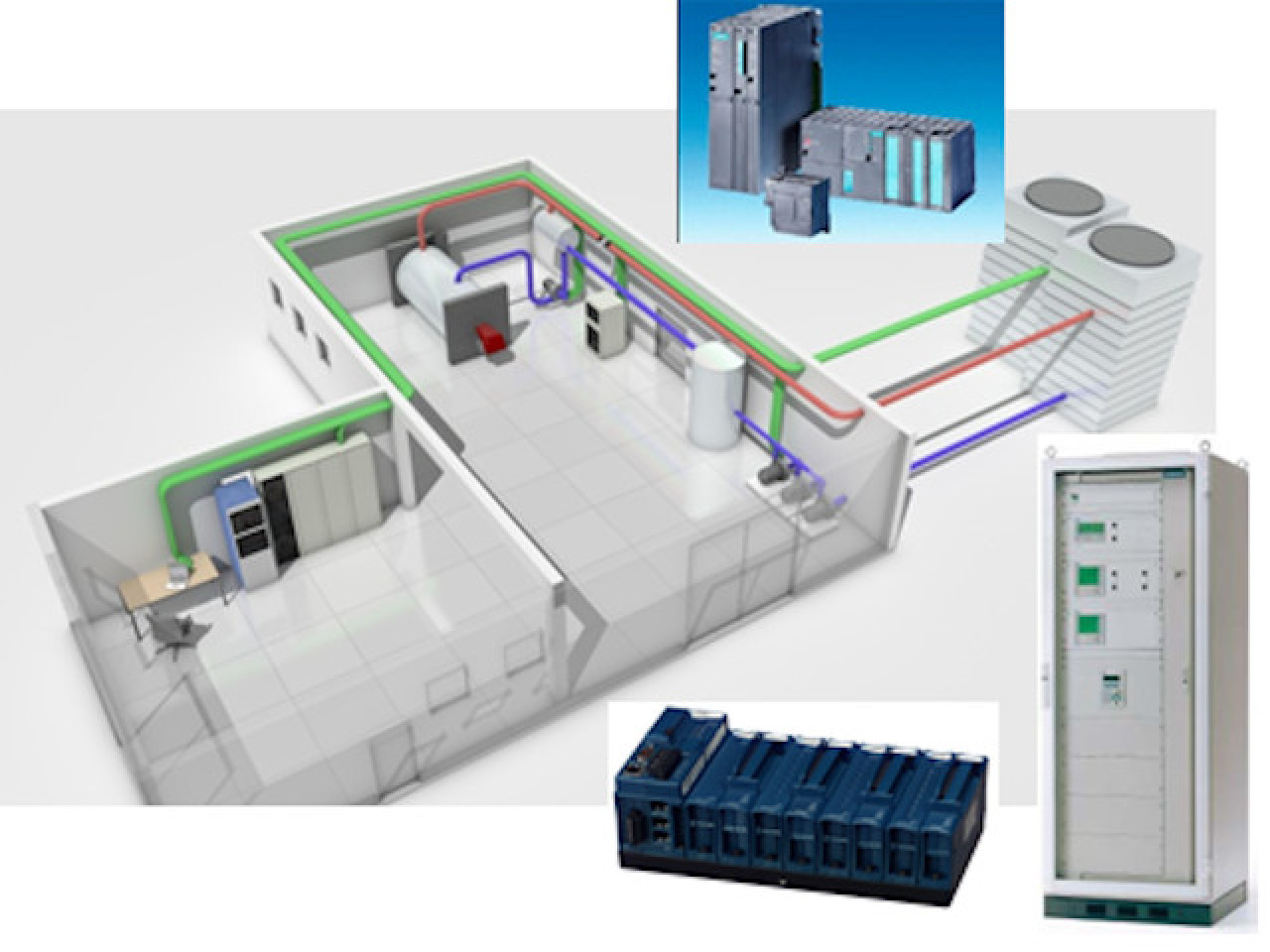

Diagram of an automated R&D laboratory

Diagram of an automated R&D laboratory

Total customisation of software and users' graphic interfaces. Ability to conduct high automation level standard tests or to create ad hoc tests for specific requirements. Integration in the measurement software of applications able to recalibrate then instruments without detaching them from the thermometric chain, with simple and automatic procedures, storing all calibration data in standard format and assuring their continuous traceability.

All research laboratories of companies in the mechanics, energy systems and oil&gas sectors can avail themselves of instruments designed specifically for their measurement, analysis and control needs. This type of test benches may significantly simplify research and development activities, by making tests quick and standardised, offering an immediate view of the physics of the phenomena under study, at the same time as providing extremely flexible instruments for data acquisition.

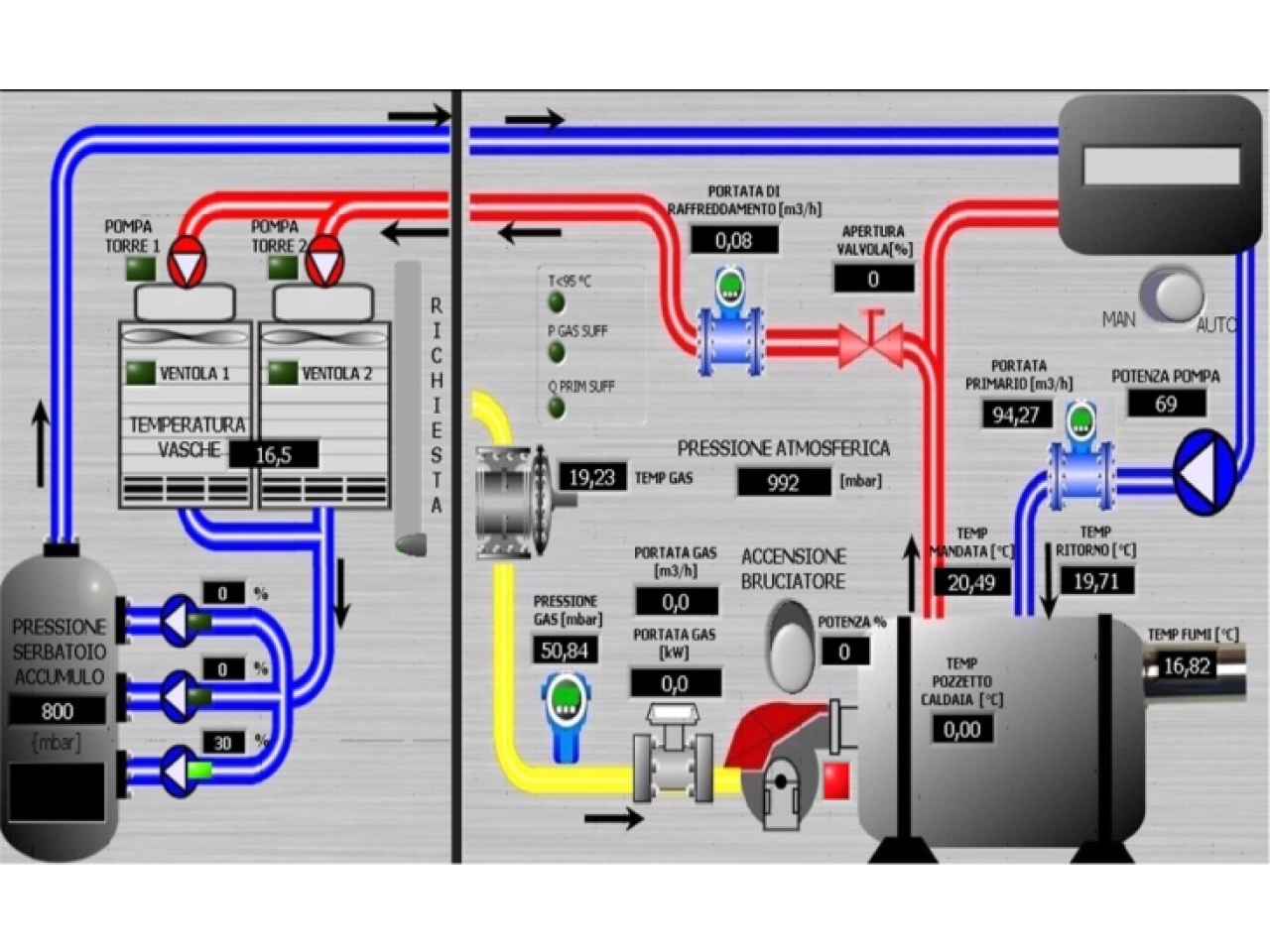

User interface to manage an automated test bench

User interface to manage an automated test bench

Development of labview architecture for simultaneous management of multiple test benches for industrial boilers and burners

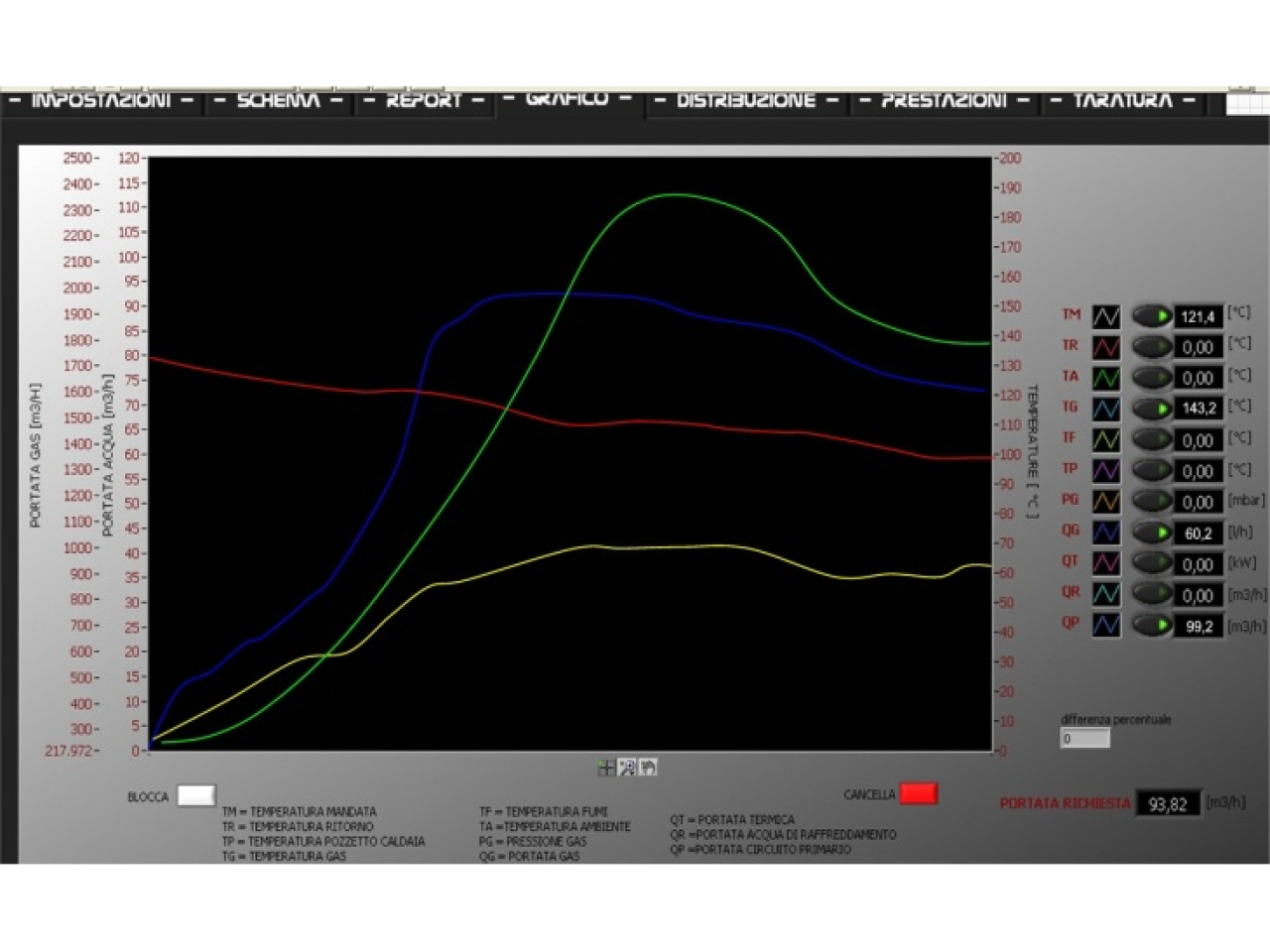

MechLav was involved in developing the computer data acquisition and automatic control system of the test benches during implementation of a new system to test boilers, burners and combined units at Thermital's headquarters. The laboratory supports a wide range of tests on medium and large sized boilers, as well as on gas burners and wood and pellet systems; up to four units may be tested simultaneously, with independent acquisition and control systems. The use of different PLCs for the various functions has made it necessary to develop a common language for the various systems to communicate (National Instruments, Siemens, IMO): in the acquisition and control program, the entire system may be displayed on a single screen and it is possible to interact with it. Upon starting up, calibration updating of each sensor is checked and the possible need to recalibrate the system is signalled, a function performed through an integrated application which provides and stores the calibration line and/or percentage error for each sensor. Updated calibration coefficients are thus always employed in a traceable way. Two types of report are produced: the Synthetic Report provides a 'snapshot' of the system's operation in certain stationary conditions; the Linear Report displays all the acquired values and the temporal evolution of the various quantities. High automation of the laboratory's test and analysis processes; reduction of product development time and costs; control and certification of the accuracy of the measuring chains with data traceability. Furthermore, the integration of prototype experimentation with thermo-fluid-dynamic simulation, helps designers in obtaining robust calculation models, thus boosting the entire development process.

THERMITAL (RIELLO Group)

MechLav is interested in developing projects like these with other companies, aimed at designing automated test benches that best address the needs of each specific research and development laboratory, identified through close interaction with company researchers.

Example of test report output

Example of test report output