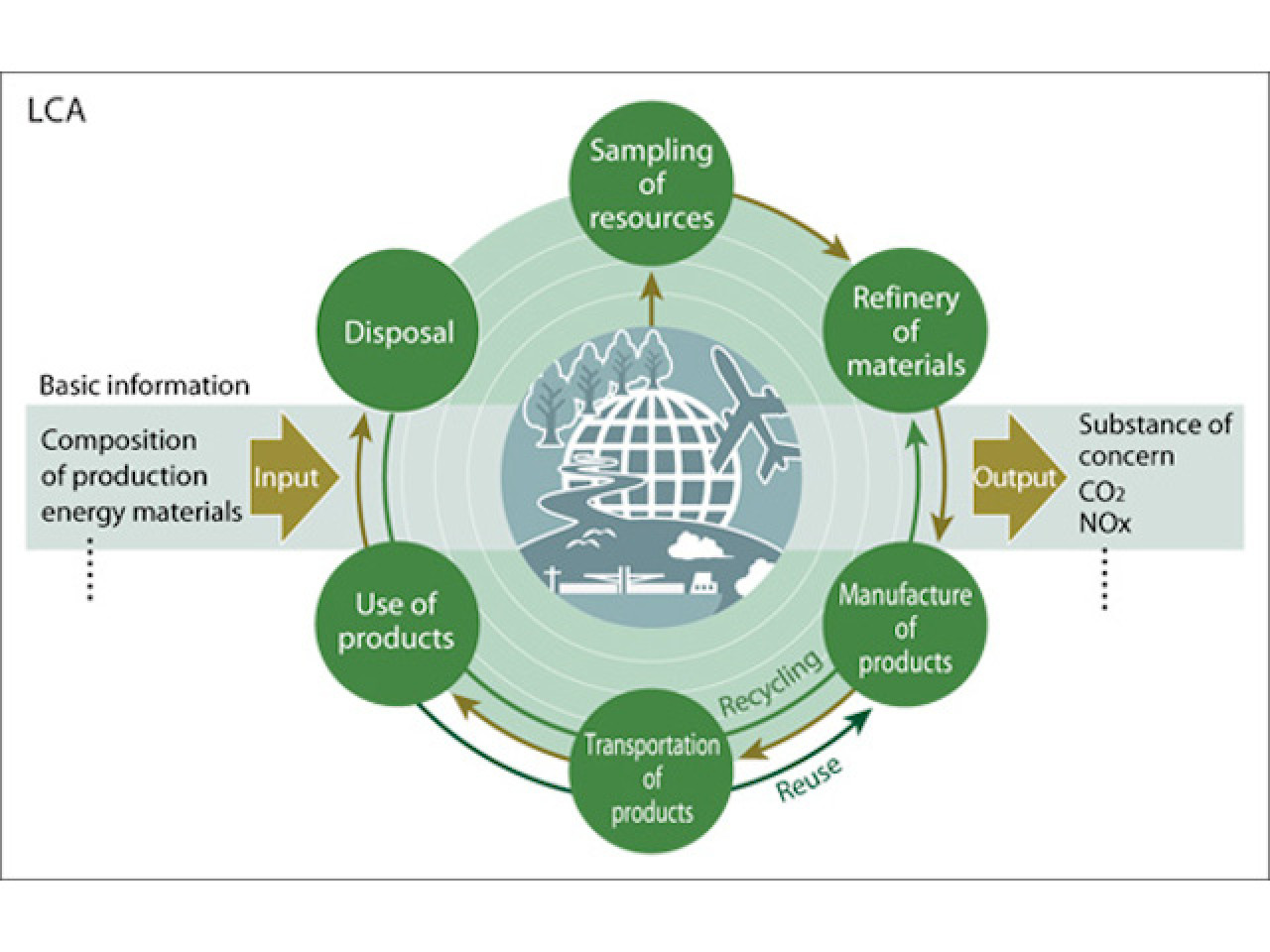

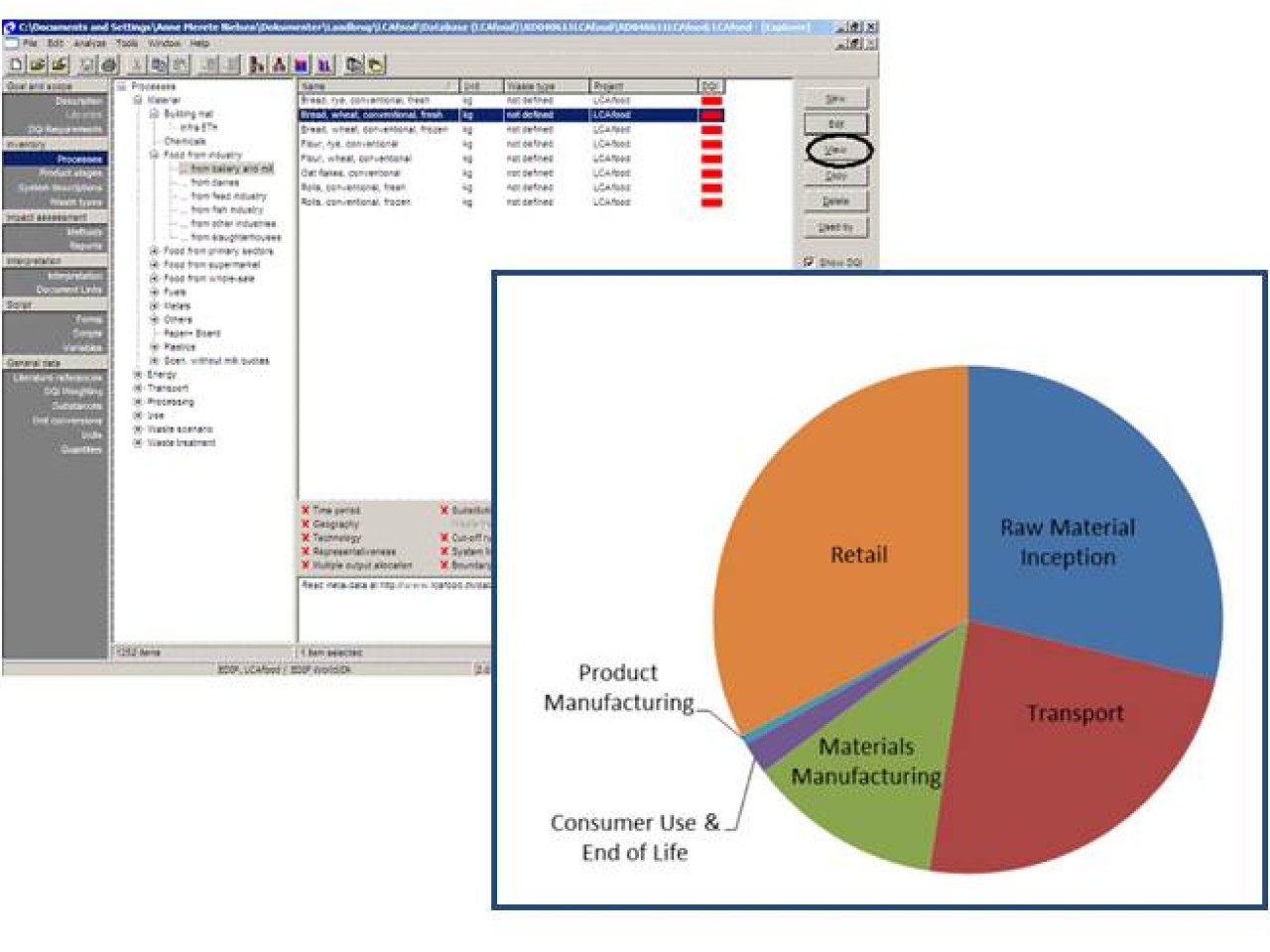

Life Cycle Assessment (LCA) is a methodology that assesses a set of interactions a product or service has with the environment, considering its entire life cycle including the stages of preproduction (therefore also materials extraction and production), production, distribution, use. Includes, therefore, also reuse and maintenance procedure is standardised at international level by ISO standards 14040 and 14044. LCA analyses are carried out with the SimaPro software, using several databases with thousands of processes, as well as the most significant impact assessment methods.), recycling and final disposal.

Life Cycle Assessment - LCA

Life Cycle Assessment - LCA

The LCA service supports companies and public administrations' decisional processes in designing and developing products, processes or high environmental performance services. It entails an adaptation of database to local realities. Furthermore, there is the possibility to generate simplified analysis tools obtained from full LCA analyses, by means of which the damage caused by pre-defined unknowns may be calculated, without using the computational code. All LCA analyses calculate internal and external costs. Support is provided towards obtaining environmental product certification (EPD).

1. Environmental impact analysis of waste disposal in different systems (landfill, incineration, composting, etc.) 2. Life cycle analysis of: - agrifood products - urban and suburban traffic - buildings - products both on an industrial and laboratory scale - energy production 3. Calculation of the environmental damage due to: - production, in a scenario of end of life use - production of thermal and electric energy obtained from fossil fuels, biomass, renewable sources - extraction of raw materials and processing required for their use.

Analysis of environmental critical issues

Analysis of environmental critical issues

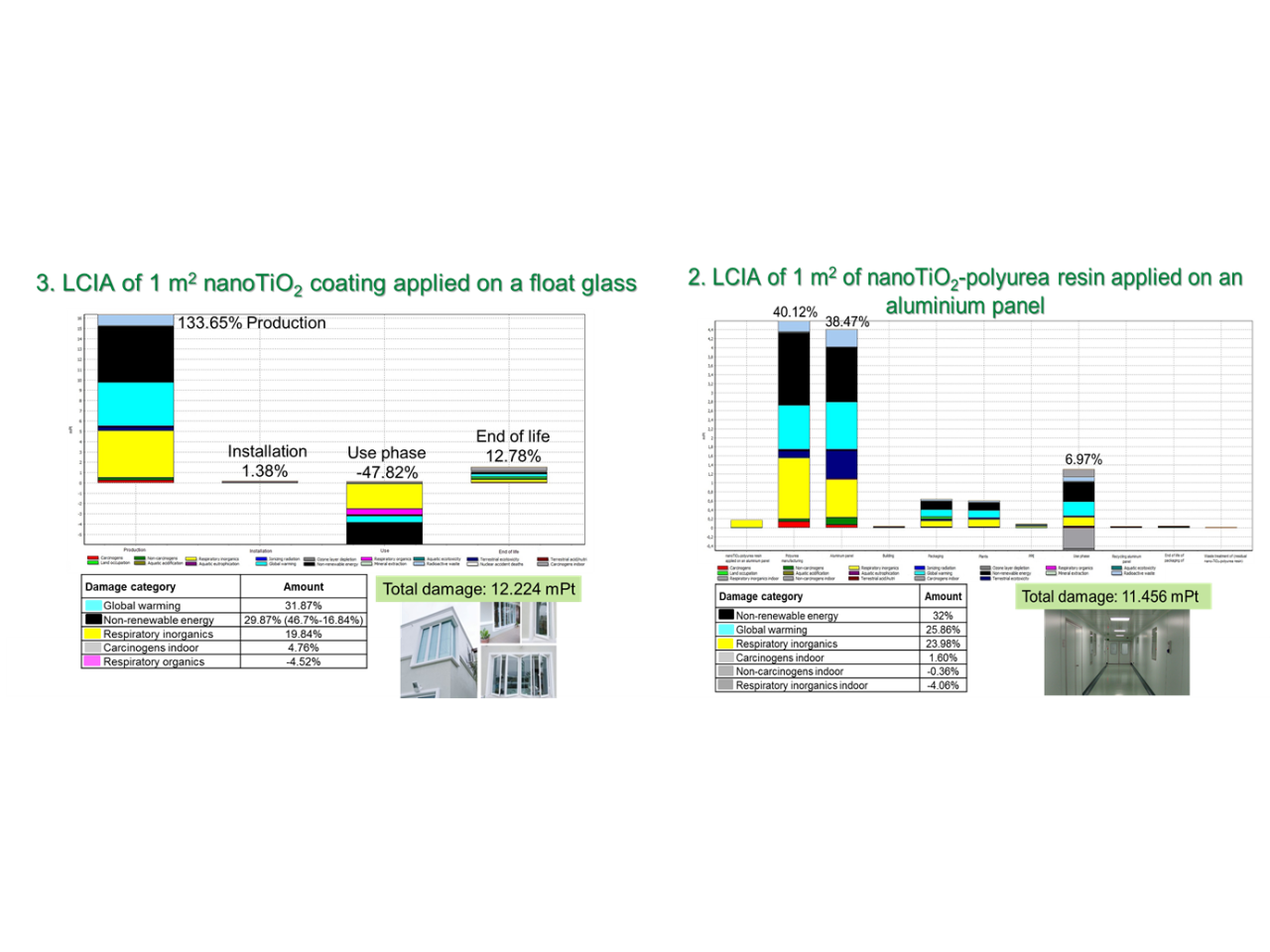

Environmental sustainability analysis of innovative materials for environmentally sustainable constructions

The activity carried out has contributed to exploring the environmental performance of new application solutions of materials having higher technological properties than current ones, both in the research stage and in the scale-up stage. Specifically, the environmental impact has been ascertained of materials and technologies to implement a range of categories of functional surfaces, that will form part of indoor and outdoor architectural and decoration elements and for which the supply chain cost in environmental terms according to the LCA model paradigm has been quantified (Life Cycle Assessment): - antismog, self-cleaning, anti-bacterial, anti-scratch, anti-slip flat glass panes; - anti-scratch, anti-bacterial resins; - metals coated with porcelain enamel with antismog, self-cleaning, anti-bacterial, anti-scratch, anti-slip, non-stick properties, resistant to attack by strong organic and inorganic acids and bases. Environmental damage quantification with various assessment methods: 1) Aluminium panel coated with polyurea resin two-component functionalised with nano-TiO2. 2) Self-cleaning float glass functionalised with -TiO2. Analysis of higher environmentally critical impact and damage categories and their proposed reduction by adopting new technological elements in the productive process and alternative end-of-life scenarios

Colorobbia Italia S.p.A. Via Pietramarina, 53 - 50053 Sovigliana Vinci (FI)

SRS S.p.A. Via Marzabotto, 12/14 - 41042 Fiorano Modenese (MO)

All the activities were performed to support and guide the design choices of involved partners. LCA analyses have highlighted to companies the path with the least environmental impact for possible industrial scale-up of the analysed products.

Environmental impact of analysed systems

Environmental impact of analysed systems