Advanced software tools able to reduce the costs and impact of freight traffic generated by industrial districts taking advantage of the co-location of a number of companies. The nature itself of the Italian virtual enterprise, based on a complex supply network whose nodes are geographically distributed, assures great flexibility but generates heavy traffic especially on the short-medium range (within 150 kilometres). The establishment of industrial districts concentrates companies, even belonging to different supply chains, thus creating the conditions to aggregate the demand for haulage assuring a higher degree of saturation of the vehicles and advantageous cost sharing. The tools under development are designed to make the most of this situation providing a service that optimises the use of resources, with benefits both for manufacturers and carriers.

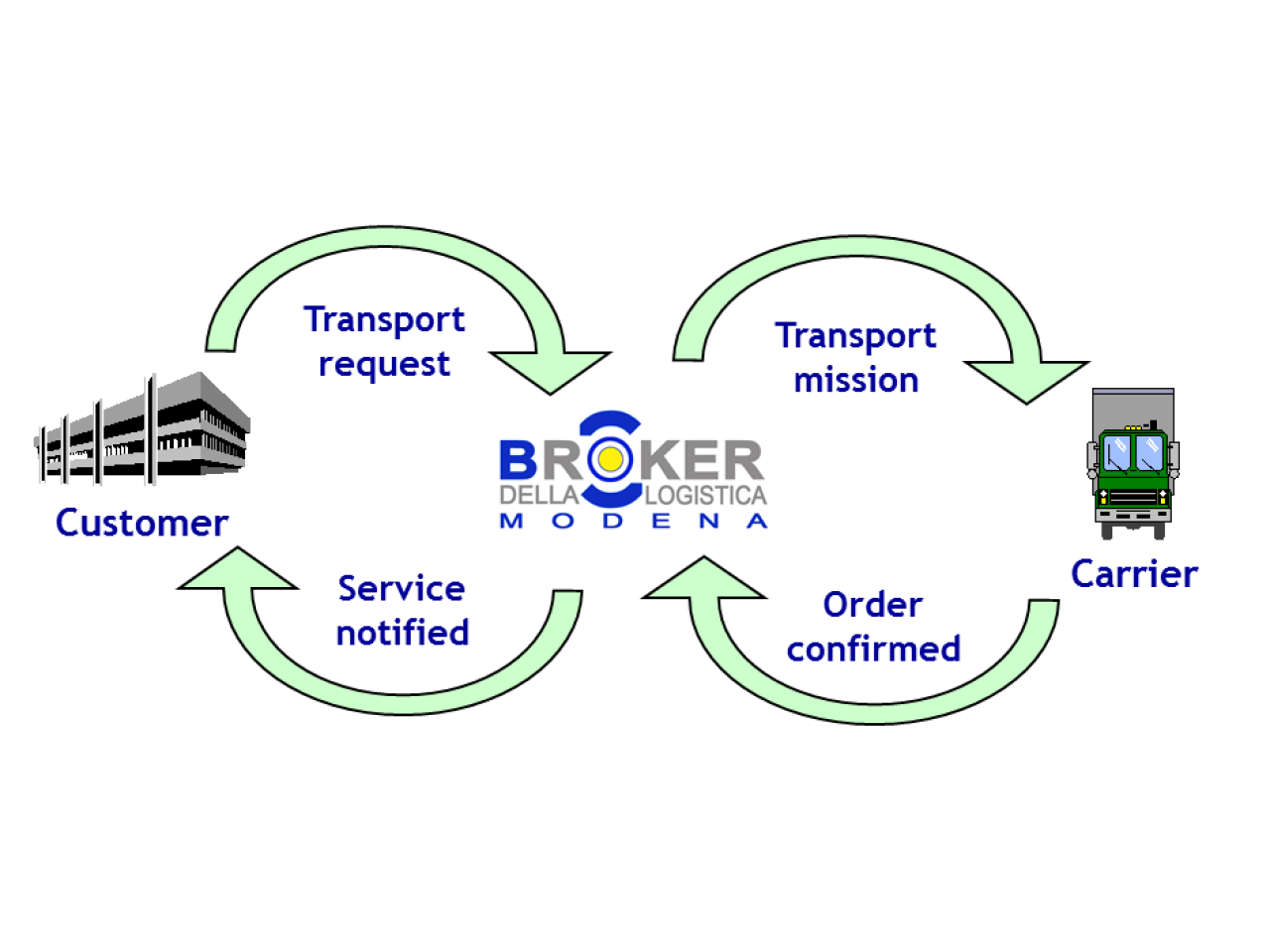

Functional model of the logistics service.

Functional model of the logistics service.

This intermediation service features four important innovative aspects: it allows client companies to forget the logistics problem, entrusting the broker with the task of solving it; it offers to accredited carriers a finally organised request instead of the current piece-meal one; the mission calculation algorithm has been validated in the field by logistics experts and despite its simplicity it produces absolutely valid results; and it does not require special logistics expertise from the broker but simply the ability to assess the performance indicators calculated by the system.

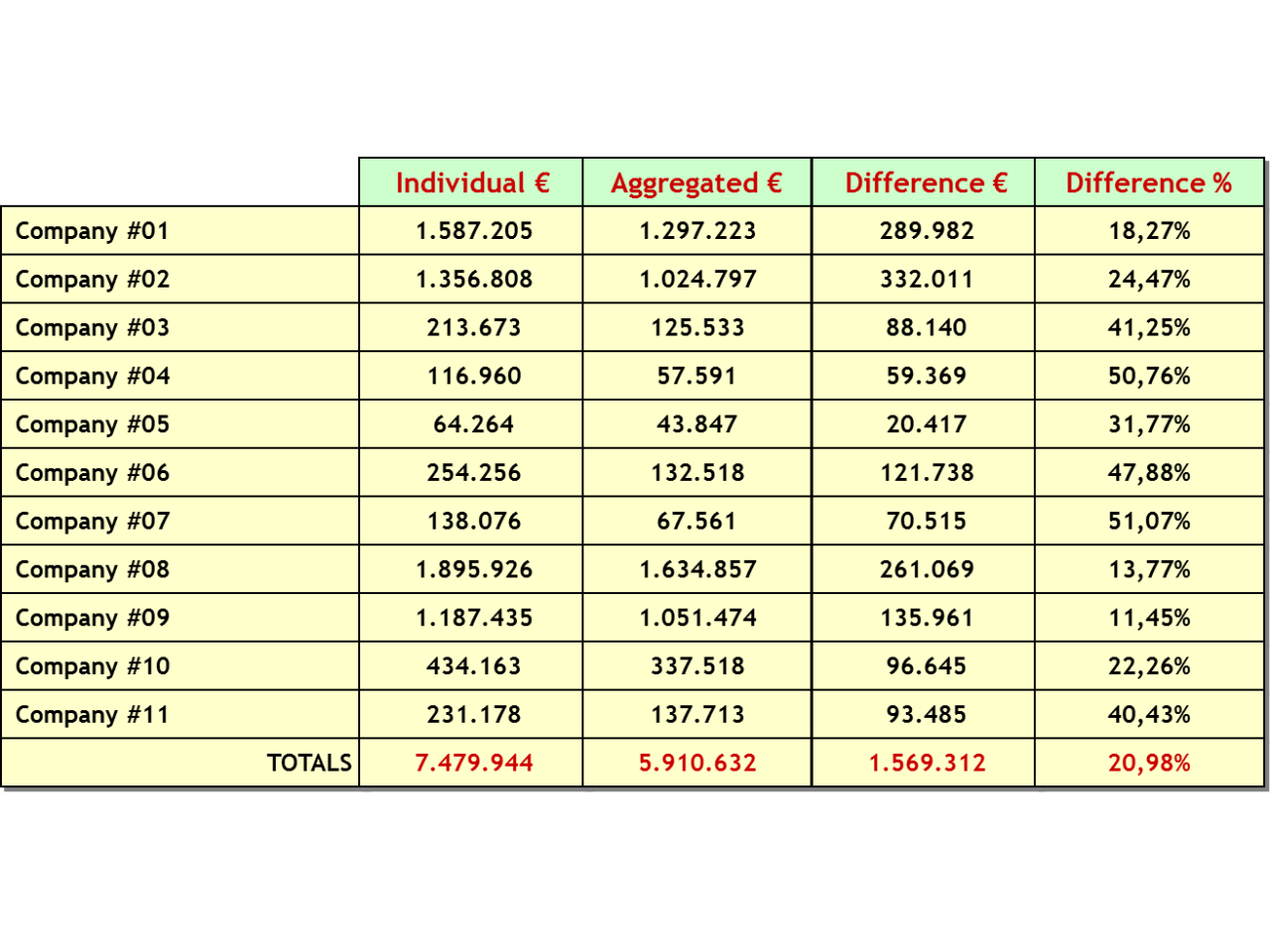

The system entails two main utilisation models: by a group of production companies (possibly located in the same district) which decide to share transport vehicles, or by a haulage company which intends to plan its activities using both its own vehicles and those of contractors it has entered agreements with. Over the last few years, both approaches have been tested in the field with highly significant results in terms of cost savings, exceeding 20% compared to the traditional individual model.

Outcome of one year of experimentation with 11 companies of varying sizes.

Outcome of one year of experimentation with 11 companies of varying sizes.

PIP 10 Industrial district, Modena.

The software platform, developed in open-source technology, has been installed on a Laboratory server and made accessible to the broker, to the 11 companies and to three carriers. The experimentation lasted one year according to the following methods: Each client company loads the haulage requests providing the required information. The user receives from the system the result of the mission calculation, from which they learn which vehicles will come to collect the loads, at what time, and when these loads will be delivered to their destination. First of all, each contract carrier provides the haulage price list. Then, they receive the proposals for the missions to be made every day with their price already calculated based on the shared price list, and they respond by either accepting or rejecting each mission and relevant conditions, so that the system may definitely assign the job or seek another supplier. The broker performs the mission calculations on the request from clients, assesses the quality of the calculated missions to decide which to maintain and which to take down and re-calculate by modifying some parameters of the algorithm, and finally submits the result to the selected carriers. On a regular basis, the broker uses the computer instrument to calculate proforma invoices for clients and suppliers

Transport and Logistics Institute (ITL), Productive Activities Consortium (CAP) of the Modena province. 11 companies of the district

The software platform is still available to companies who wish to make use of it. At the moment it is being experimentally used by some Italian manufacturing and haulage companies and by a group of Polish pharmaceutical companies. Utilisation is under study with other companies in Modena and Bologna and with similar companies in Croatia, France, Slovenia and Spain

Load aggregation to saturate haulage vehicles.

Load aggregation to saturate haulage vehicles.