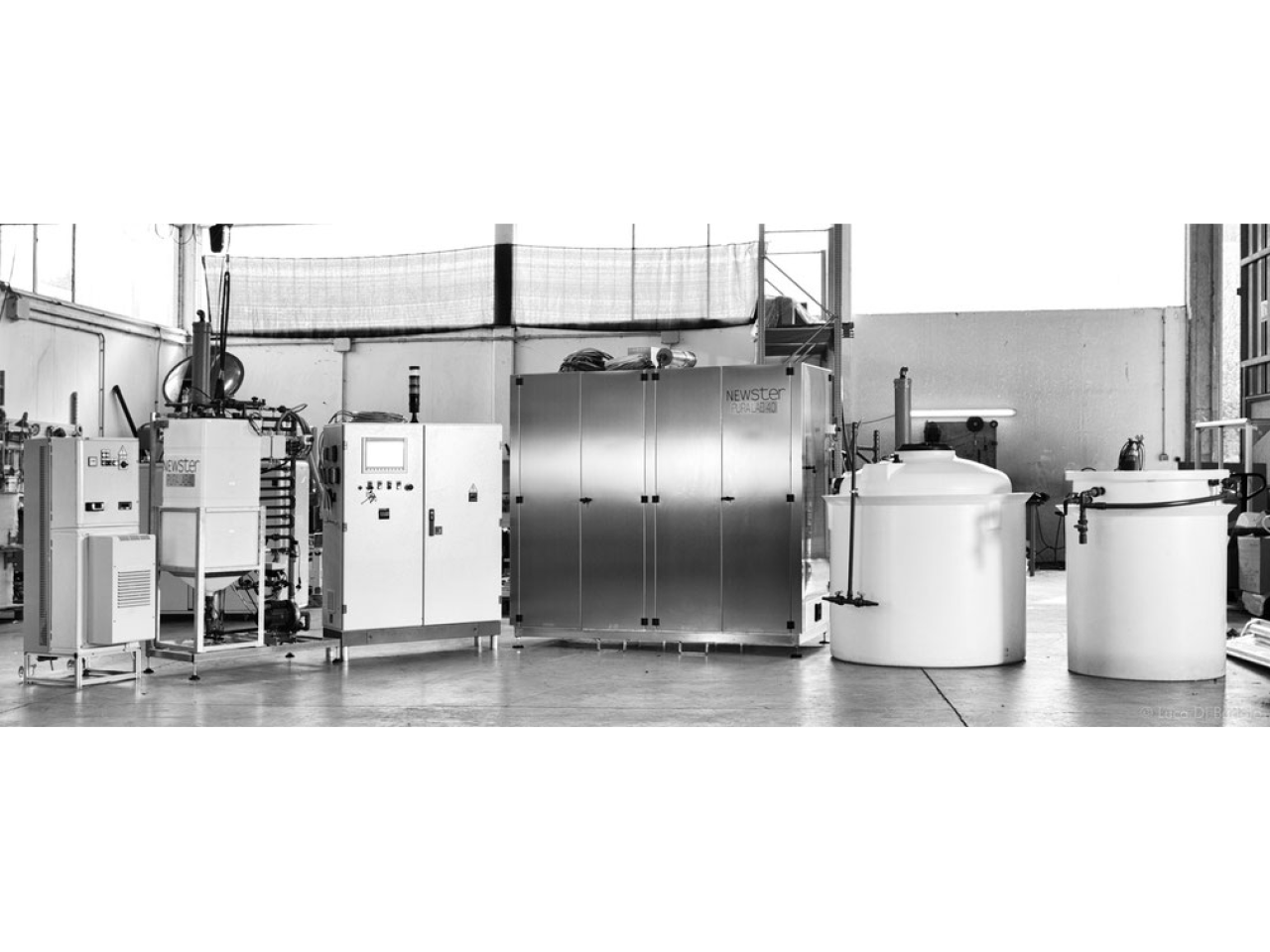

The 100L prototype plant realized (upscalable at 150L) allows the neutralization of liquid waste products of the analysis laboratories and verification of the treatment before the final discharge into the sewer. It can be installed at the laboratories themselves. The treatment plant has the following characteristics: - reduction of at least 50% of the COD level (Chemical Oxygen Demand) of treated wastewater - abatement within table values of the bio resistant chemical pollutants contained in the wastewater - presence of control software adaptable to various operating conditions - small size, such as to guarantee on-site installation in the laboratory facilities - limited costs, such as to make it marketable even in developing countries - zeroing of the infectious/biological risk of liquid waste potentially capable of infecting the staff assigned to work activities.

Decontamination & Oxidation of Medical laboratory fluid wastes

Decontamination & Oxidation of Medical laboratory fluid wastes

The plant uses a strong oxidation reaction mediated by the hydroxyl radicals produced by the advanced oxidation process (Fenton reaction), finely optimized for the matrix of interest, which guarantees the treatment of wastewater from the laboratory to protect environment. The prototype is equipped with an ozone production module mixed with the wastewater. The ozone generation module can be used both on the wastewater to be treated and on the clarified one, with reduction of surfactants and buffers.

The treatment plant can be used by public or private clinical analysis laboratories and by any production or service company that has to provide for the disposal of clinical laboratory waste, through plant installation on the site itself.

Innovative neutralization treatment plant for liquid waste products from analysis laboratories, which can be installed at laboratories themselves.

Innovative neutralization treatment plant for liquid waste products from analysis laboratories, which can be installed at laboratories themselves.

Prototype for the treatment and neutralization of medical laboratory liquid waste

The prototype uses a strong oxidation reaction mediated by the hydroxyl radicals produced by the Fenton process, a well-known advanced oxidation process. The wastewater undergoes a finely optimized Fenton process: in a first phase they are heated to a suitable temperature, then they undergo an oxidation reaction that allows the destruction of common pollutants, especially the organic ones. The liquid is then neutralized and the solid particles precipitate and are separated from the liquid phase by a system of mechanical filters. At the end of the cycle, the clarified liquid is cooled in a collection tank and then discharged into the municipal sewerage system in accordance with the legal limits. The cycle is controlled by a SIEMENS PLC which allows the operator to monitor each phase of the cycle through the animated synoptic diagram. The automated operation of plant is guaranteed by the control of multiple reaction parameters (pH, redox, temperature, tanks levels, etc.). The prototype has a capacity of 100 l/cycle. Each cycle lasts about 150 minutes, so the average productivity is 40 l/h.

Newster System s.r.l.

The product obtained the patent in the USA, Russia and is pending in Europe. It is found in the Newster System product range, available for the market. The benefits of the project on the Emilia-Romagna production chain concern both the development of methodologies for water sanitation and decontamination, and the cost reduction for healthcare facilities.

TrueLab is a patented treatment specific plant for waste medical laboratory fluids to remove biological and chemical hazards from the discharged water.

TrueLab is a patented treatment specific plant for waste medical laboratory fluids to remove biological and chemical hazards from the discharged water.