Paper, a staple of human civilization for centuries, is not without drawbacks.

Its hydrophilic nature and porous structure are some of the limitations of this material, making its application particularly problematic in wet environments or in direct contact with water.

Nanoprom Chemicals has developed and tested a coating to protect paper from water and moisture.

The coating is based on patented sol-gel processes. The starting material is a colloidal suspension of solid particles in a liquid, the "sol", which is transformed into a gel through hydrolysis and condensation processes. Following drying, the material completes its polymerization cycle.

Polysil Paper is a transparent silica-based coating. With a layer of a few micrometers, the product creates a glass-like layer on the substrate, without altering its aesthetic appearance but imparting distinct hydrophobic properties to the surface.

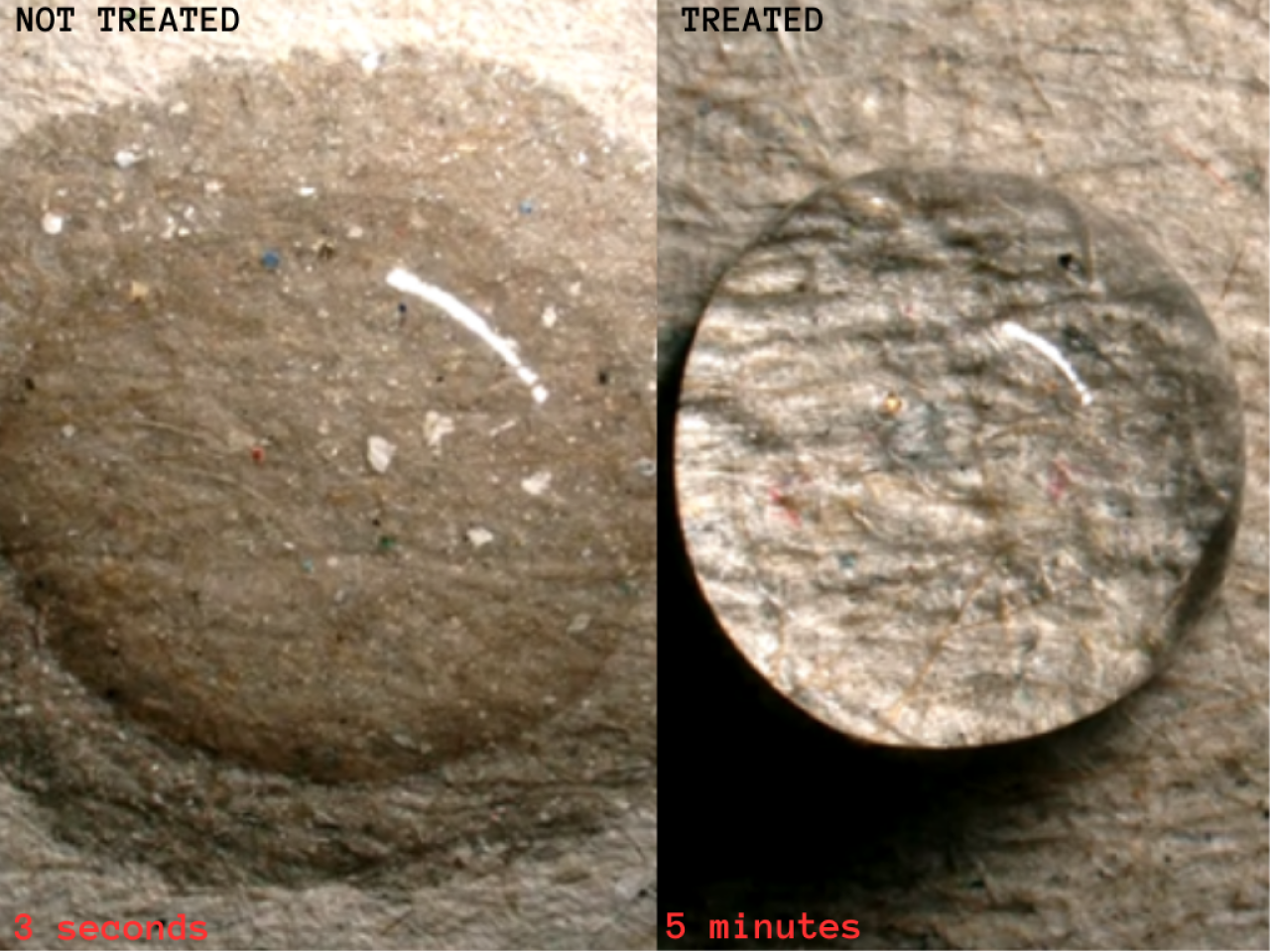

Figure 1: Keyence VHX-6000 digital microscope observation of a water drop deposited on untreated (after 3 seconds) and Polysil Paper-treated (after 5 minutes) cardboard

Figure 1: Keyence VHX-6000 digital microscope observation of a water drop deposited on untreated (after 3 seconds) and Polysil Paper-treated (after 5 minutes) cardboard

The main problem associated with all packaging made of paper and paperboard, as well as all cellulose-based consumables, is their susceptibility to water absorption, which causes them to soften when exposed to a particularly humid environment or water. This behavior depends mainly on water-cellulose molecular interactions, coupled with paper's high porosity and capillarity phenomena.

To address this problem, Nanoprom has developed Polysil Paper, a coating that is based on sol-gel principles that, once applied, penetrates the structure of paper or cardboard. The polymerization reaction, which takes place at room temperature, leads to the formation of siloxane bonds (Si-O-Si), with the formation of an amorphous silica layer, which leaves the substrate optically unaffected.

The main characteristics of this coating include remarkable hydrophobicity, due to the presence of highly apolar groups in the precursors, and a low surface tension, close to 20 mN/m. This creates a kind of " barrier effect" between water and the underlying material.

In addition, treatment with Polysil Paper does not absolutely compromise the ability of paper substrates to absorb water. This allows some permeability to moisture and/or water in case the material is abandoned, with the possibility of still having bio-degradation, albeit over a longer period of time.

The ability to make paper and cardboard impermeable, or at least semi-impermeable, to water represents a significant breakthrough in many applications, as it allows plastics to be replaced in many areas. One tangible example involves single-use items (such as plates, straws, and cutlery) that used to be commonly made from plastic but, as of today, this is no longer possible due to new European directives. Paper proved to be the most promising choice for replacing plastic, but it presented and still presents the well-known problem of water absorption.

To address this challenge, Polysil Paper was tested on plates, straws and other paper-based packaging materials. The treatment was able to completely eliminate the softening problem.

In addition, it is essential to point out that Polysil Paper has already undergone rigorous food evaluation and testing, confirming its safety for food contact. The treated substrate also remains fully recyclable, as demonstrated through recyclability tests conducted in cooperation with a local laboratory.

The applications are the most various and disparate. Protection of packaging cardboard for reduction or elimination of outer plastic, protection of disposable items such as straws, cutlery, glasses and plates to impart greater resistance when in contact with water and beverages, protection of disposable countertop paper.

Figure 2: Polysil Paper application on cardboard by spraying.

Figure 2: Polysil Paper application on cardboard by spraying.

Deposition by spraying Polysil Paper on cardboard for industrial use in finished product packaging and on cardboard used as a spacer between sheets (interlayers).

The application of Polysil Paper was conducted directly at Nanoprom, inside a spray booth. The cardboards were treated by spraying, and once the coating cured, they were used for packaging material for the customer.

Next, a comparative test was conducted by exposing two pallets outside: one containing material packed with treated cardboard and the other with untreated cardboard. The results obtained after a period of five months outside (November-April) show that the treated cardboard is still completely intact and the printing ink completely preserved. In the case of the untreated board, clear signs of deterioration are observed and the pre-printed markings are difficult to read.

In the examination of the interlayers, it was noted that the Polysil Paper-treated board remained completely intact and did not cause the release of pollutants on the surface of the slabs. In contrast, the untreated interlayers showed obvious signs of deterioration (Figure 3); moreover, this caused the formation of stains on the slabs, which were difficult to remove.

Companies in the district of Sassuolo

Polysil, from which Polysil Paper derived, is a coating protected by several national and international patents, on which a product LCA was performed. The solution has been presented to several companies facing the problem of wettability of packaging.

Treated interlayer (upper left) vs. untreated interlayer (upper right). Slab surface in contact with treated interlayer (bottom left) and with untreated interlayer (bottom right)

Treated interlayer (upper left) vs. untreated interlayer (upper right). Slab surface in contact with treated interlayer (bottom left) and with untreated interlayer (bottom right)