Rivers, drainage and irrigation channels maintenance produces high amounts of waste biomass that can be divided into two macro-types: wood residues that are normally recovered and supplied as fuel to biomass plants and herbaceous residues that are left to degrade on the embankments. This biomass degrading releases methane, a gas 20 times more climate-altering than CO2, in addition the biomass can ends up in the river / channel bed due to precipitation slowing down the passage of water. PYROMAT solves the problem of managing these waste by creating a virtuous atmospheric carbon storage system. In fact, the prototype is a small-scale pyrolyzer that transforms herbaceous waste into char and combustible gas. The gas is self-consumed to support the pyrolysis reaction while for the residual char the INTERMECH researchers have found an application in the field of building materials.

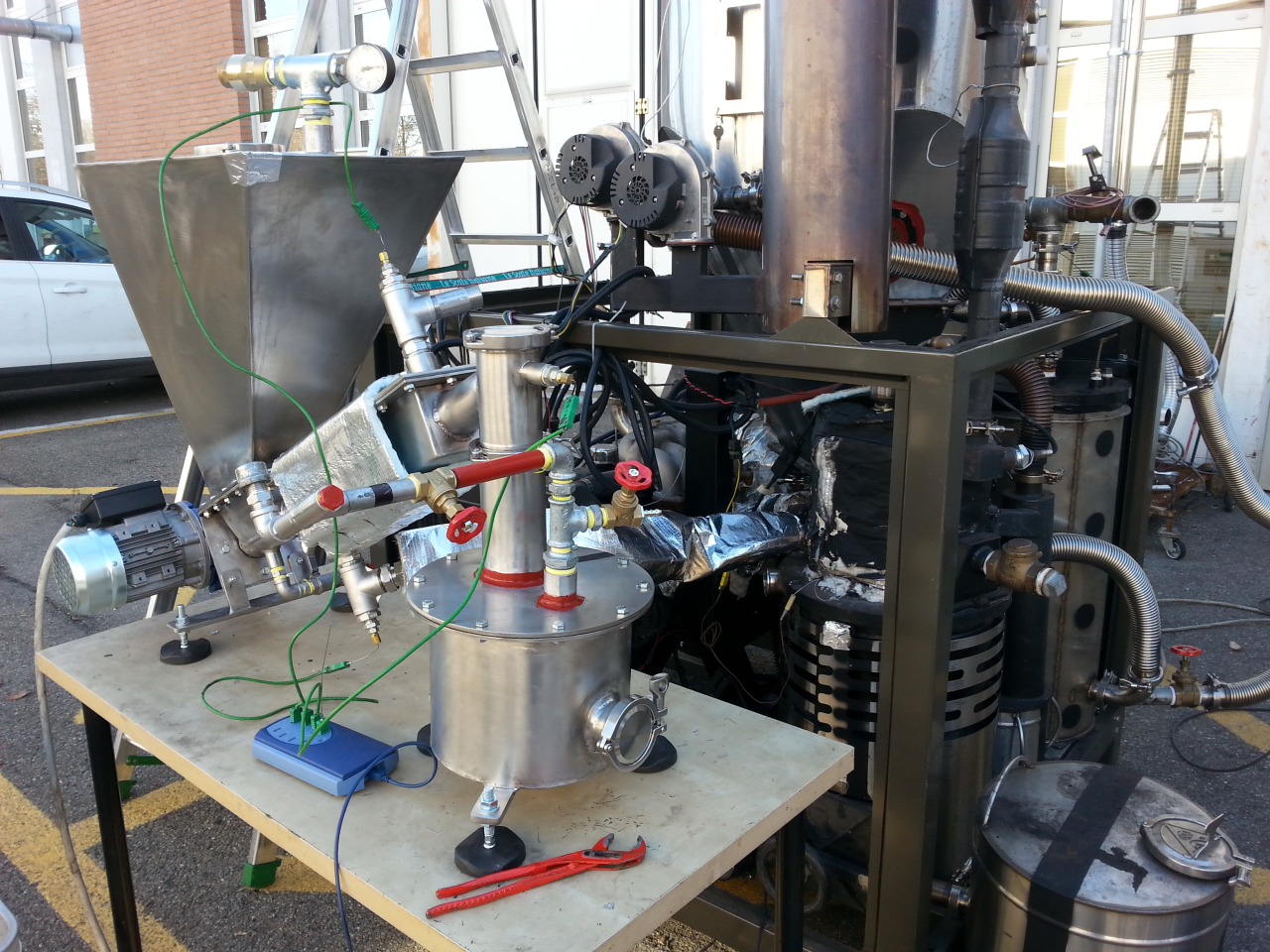

PYROMAT screw-type pyrolyzer prototype with loading and unloading hopper

PYROMAT screw-type pyrolyzer prototype with loading and unloading hopper

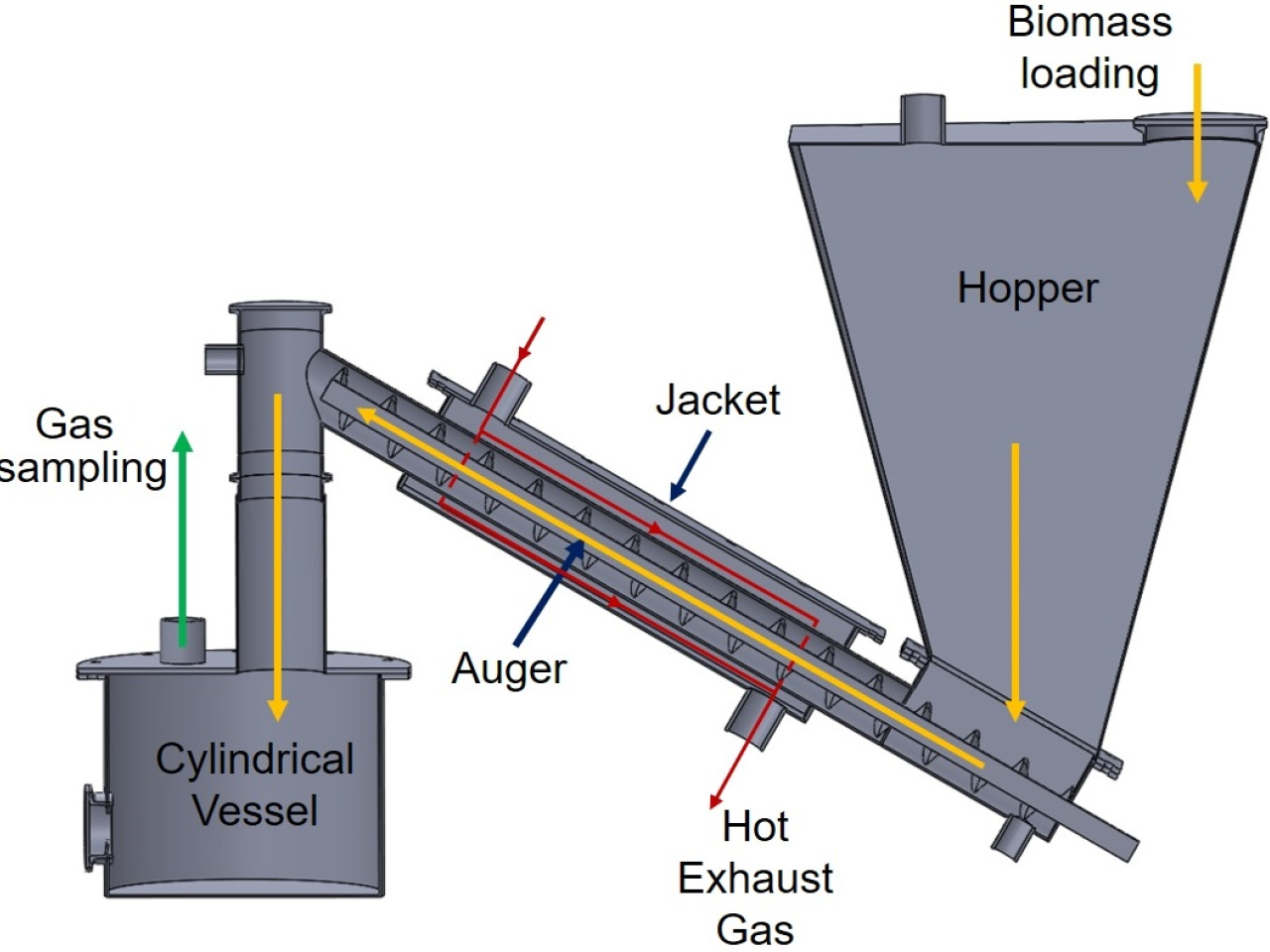

The PYRO-MAT system coupled with a commercial gasifier generates a pyrolysis gas which, instead of being combusted in the atmosphere with high pollutant emissions due to the high content of tar inside itself, is used as fuel of a wood chip gasifier. In this way, there is a very high efficiency energy recovery, low emissions from the internal combustion engine of the gasifier and a solid by-product called char with about 50 recognized applications.

The potential char applications are: - additive for building materials such as plasters, cements, concretes and expanded polyurethanes - additive for clay-based NPK solid fertilizers - soil improver - raw coal material to be activated with chemical / physical processes

Operating scheme of the PYROMAT pyrolyser

Operating scheme of the PYROMAT pyrolyser

Pyrolysis of herbaceous residues from river maintenance and production of char as additive in polyurethane building materials

PYROMAT has been tested as part of the POR-FESR REBAF project in which a part of the residual biomass from the maintenance of the Secchia river has been divided into a wood fraction and a herbaceous fraction. The wood fraction was used as fuel in a commercial gasifier supplied by the company Syn-gas s.r.l.s. The gasifier was then connected to the PYROMAT pyrolyser where the shredded herbaceous fraction was treated. While the gasifier produced electricity and heat, char was obtained from the pyrolizer. Char was added as filler in polyurethane panels used as insulation in buildings. The addition of up to 2% by volume of char increased the quality of the material, in fact it increased its mechanical strength and electrical conductivity and it has slightly reduced thermal conductivity. Furthermore, the trapped char in the polyurethane matrix is 70% composed of carbon deriving from the starting biomass which used atmospheric CO2 to grow. If we want to refer to the starting biomass, pyrolising 1 kilogram of dried biomass, the obtained char contains about 300 grams of equivalent CO2 that it can be physically stored in building materials as an additive or in soil as soil improver.

INTERMECH MORE CREA CIDEA CIRI-MAM BOSCHIVA F.lli Valentini s.r.l. Syn-gas s.r.l.s.

In the future, the system will be more automated in order to have a continuous biomass supply and a continuous unloading of chars without interruptions. PYRO-MAT will be proposed as an appendix of commercial gasifiers in order to have a complete system capable of use heterogeneous biomass.

Starting from the left: shredded biomass, char, and a polyurethane panel with 2% vol. of char

Starting from the left: shredded biomass, char, and a polyurethane panel with 2% vol. of char