Plasma-assisted Ionized Jet Deposition (IJD) is a technology enabling the fabrication of surface coatings from various materials. Its operating principle involves a pulsed electron beam striking a target material, causing its pulverization and transition into a plasma state. The plasma interacts with the substrate surface and, upon cooling, forms a coating with a chemical composition similar to that of the starting material. This technique allows the coating of different substrates (metals, polymers, ceramics) at room temperature, supporting the development of biomedical devices by altering their surface chemical composition, morphology, and topography. The resulting nanostructured coatings, with thicknesses in the range of hundreds of nanometers, ensure excellent adhesion to the substrate.

Plasma plume during deposition process with the Ionized Jet Deposition System

Plasma plume during deposition process with the Ionized Jet Deposition System

The IJD process is a plasma-assisted deposition technique similar to the more common Plasma Spray method. Deposition process occurs under high vacuum conditions (10⁻⁷ mbar) in an oxygen or argon atmosphere, depending on operational requirements. A pulsed electron beam source (100 ns, high density, and energy of 10 J and 10⁹ W cm⁻², respectively) strikes the target material intended for the coating. Upon impact, the target undergoes ablation, transitioning into a plasma state. The plasma is directed as a plume toward the substrate surface to be coated. When the plasma plume hits the substrate, the target atoms reorganize into a structure similar to their original configuration, forming a nanometric layer on the surface. Extending the deposition time increases the coating thickness, resulting in a homogeneous and uniform coverage across the entire substrate surface.

The Ionized Jet Deposition (IJD) technology offers several advantages over existing plasma-assisted deposition systems. Compared to the more commonly used Plasma Spray technique, the IJD system provides better control and transfer of the starting material’s composition to the final coating.

This aspect is particularly important when depositing ceramic materials such as calcium phosphates, where stoichiometry and the calcium to phosphorus ratio play a critical role in determining the material’s phase. The deposition process also enables the chemical composition to be transferred without alteration, even when the starting material contains dopant elements such as metals.

Additionally, since the deposition occurs at room temperature, IJD allows for the coating of temperature-sensitive substrates, such as polymers, without causing damage — an essential feature, especially when working with 3D - printed constructs.

The use of coatings produced through Ionized Jet Deposition (IJD) in the biomedical field offers various applications:

- Achieving an Osteointegrative Effect: Selecting suitable materials can promote cell adhesion, colonization, proliferation, and differentiation.

- Providing an Antibacterial Effect: Applying a coating that inhibits the adhesion and growth of various bacterial species.

- Enhancing Surface Hydrophobicity/Hydrophilicity: Modifying the surface to increase either hydrophobic or hydrophilic properties as needed.

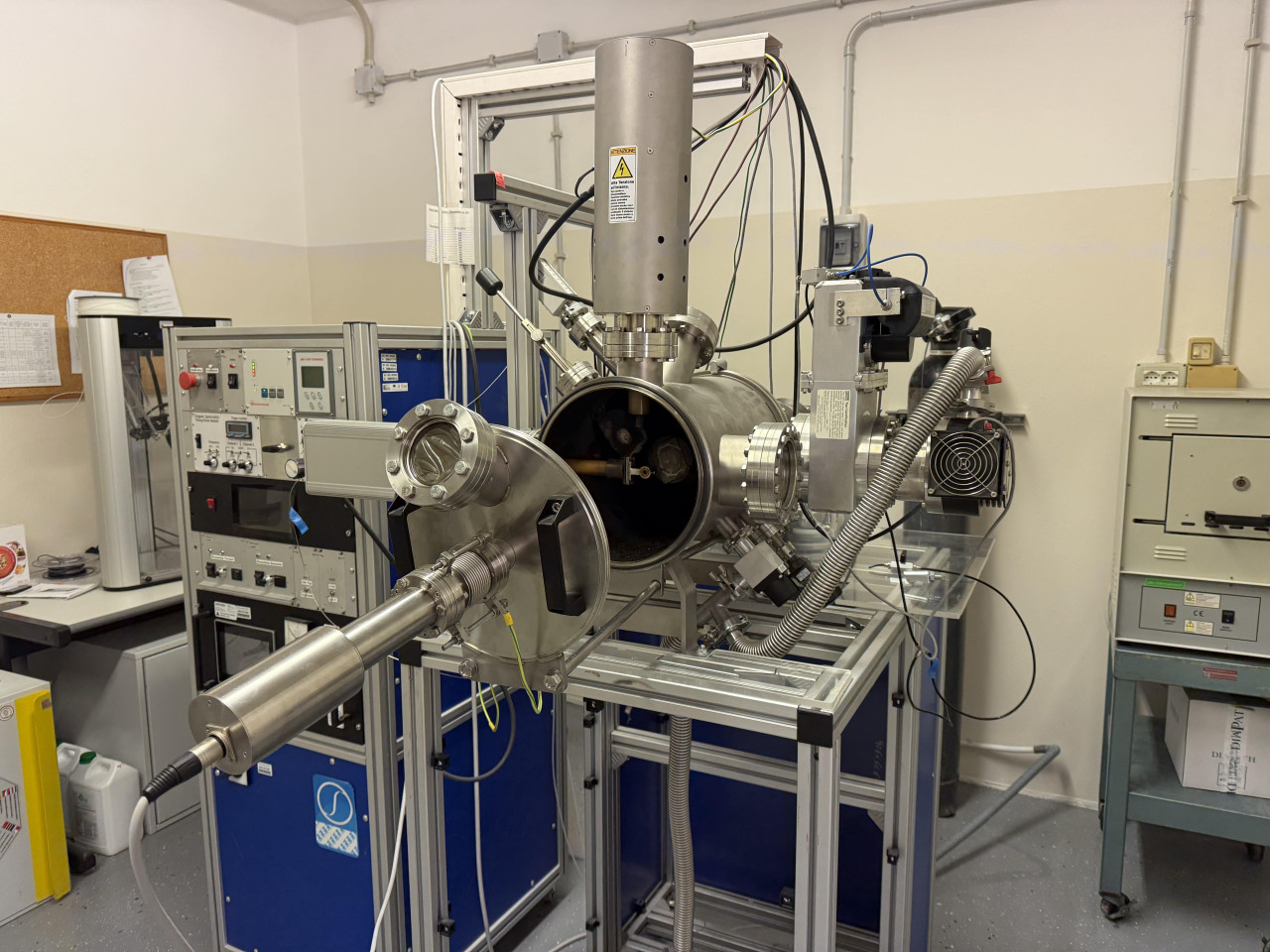

Picture of the deposition system IJD

Picture of the deposition system IJD

Fabrication of biomimetic coatings on metallic prosthetic devices to promote implant adhesion and osteointegration with the patient's bone tissue

The Ionized Jet Deposition (IJD) technique was used to coat titanium-aluminum-vanadium alloy (Grade 23 ELI) specimens with biogenic hydroxyapatite. The coated substrate consisted of a microrough titanium alloy surface, commonly considered the gold standard for manufacturing joint prostheses.

Bovine bone was chosen as the coating source due to its composition being similar to human bone. The substrates were covered with a nanometric coating approximately 300 nm thick, composed of globular aggregates with an average size of 200 nm. The substrate surface was uniformly coated, showing no surface defects.

The coating's chemical composition, in terms of crystalline phase and ionic substitution, closely resembled that of the initial target material, containing carbonated hydroxyapatite and trace elements such as Mg and Na, which are essential for cellular metabolism.

Following MSC cell seeding, the coating increased the number of focal adhesions within the first 24 hours, indicating strong cell adhesion. Gene expression analysis (RUNX2, ALP, COL1A1, and BGLAP) showed that the coating stimulated the osteogenic differentiation of mesenchymal stem cells.

- Alma Mater Studiorum - Università di Bologna

- Noivion srl di Rovereto (TN)

The increase in maturity level will require adhesion tests according to the ASTM F1147-05 standard, accepted by the EMA and FDA, as well as preclinical in vivo osteointegration tests using rabbits or sheep as animal models.

Acetabular cup and femoral stem of a hip prosthesis made of titanium-aluminum-vanadium alloy, half-coated with a silver nanocoating.nio-alluminio-vanadio, rivestite per metà con nanocoating di argento

Acetabular cup and femoral stem of a hip prosthesis made of titanium-aluminum-vanadium alloy, half-coated with a silver nanocoating.nio-alluminio-vanadio, rivestite per metà con nanocoating di argento