The TEAM SAVE project (Enabling Technologies and Materials in Advanced Solutions for the Electric Vehicle) consists in bringing to the market new technologies aimed at integrating nano-materials, additive manufacturing and secondary raw materials from recycling, in the production of components for electric vehicles that are lighter, functional, durable and sustainable in economic and environmental terms.

The introduction of nano-fibrous additives in carbon fiber composites (CFRP) and the use of structural adhesives enable new functions (health monitoring and self-sensing) and improve the performance of the components. At the same time, the use of recycled carbon fibers, used as secondary raw materials, promotes the economic and environmental sustainability of the production process, in line with European directives for the automobile.

These technologies, applied to the automotive as a demonstrator, have wide margins of use in the Aeronautics and Aerospace sectors

TEcnologie Abilitanti e Materiali in Soluzioni Avanzate per il Veicolo Elettrico

TEcnologie Abilitanti e Materiali in Soluzioni Avanzate per il Veicolo Elettrico

The project ranges from enabling technologies, such as nanotechnologies (electrospinning) and additive manufacturing, to more traditional production technologies of composite materials (press molding and autoclave curing), which will be heavily innovated both in terms of material (resins, reinforcements , adhesives, preparation of new polymeric materials for sensors and to increase toughness) and process, and concerns players distributed throughout the region with strong intersectoriality.

The materials developed find application in the sports, naval, aerospace and biomedical fields.

The use of CFRP in prosthetics can benefit in comfort from the improved ability to dampen vibrations, while the improvement in toughness guarantees a longer life.

In construction, where composites are used for consolidation, the use of piezoelectric nano-fibers can facilitate the ex-ante detection of critical fractures following slow structural or catastrophic failures, while the toughening nano-fibers increase their resilience and can limit vibrations.

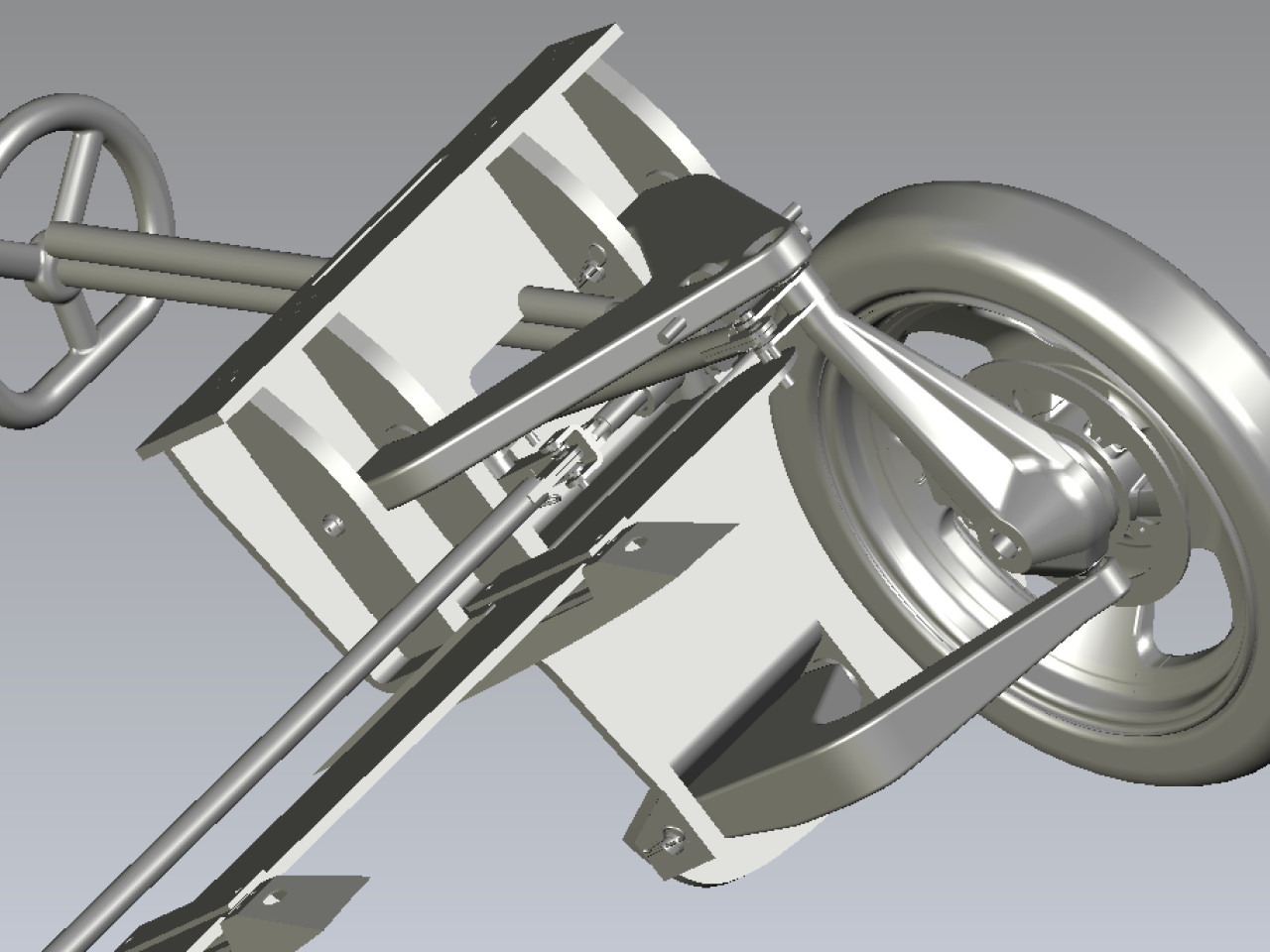

Emilia 4 front suspension system

Emilia 4 front suspension system

The project is conducted in continuity with Onda Solare, the initiative financed by the Region that led to the victory of the Emilia 4 vehicle at the American Solar Challenge 2018, and will validate the new processes and materials on some components (motor wheels, suspension system and seats) on this vehicle.

The Emilia-Romagna region has a production chain, linked to the automotive field, characterized by strong skills, and has the maturity to develop innovations that push composite material towards a more significant and integral use in the vehicle, especially as regards sustainable mobility. The challenge of proposing new production processes represents the key to the integration of innovations in the material itself. This is done through the effort of implementing Key Enabling Technologies (Nanotechnologies, Additive Manufacturing) while ensuring a Circular Economy approach of the entire process by a research on the use of secondary raw materials. The advanced materials proposed are integrated into the production of at least three components: a motor wheel, a suspension system and a seat, to be used on Emilia 4, UniBo's solar electric car. This innovative vehicle represents a highly demanding test bed for processes and materials, and the skills acquired will benefit the automotive and composite value chains in terms of knowledge and innovation capacity, with the desirable outcome of networking of the skills of the supply chain.

The partners are:

- SCM FONDERIE

- CIRI MAM

- Future Technology Lab

- CRIT

- MIND

- Elantas

- Curti

- Dallara

- Nextema

- Spinbow

The application of the proposed innovations can be inserted in fields already traditionally present in the territory with niche productions, but characterized by world leadership, such as prosthetics, or start new industrial settlements with different job opportunities, since a recycling chain of CFRPs would be a unique reality in Italy.

The solar electric vehicle Emilia 4

The solar electric vehicle Emilia 4