The use of advanced ceramics is continuously increasing thanks to their peculiar characteristics: lightness, high thermo-mechanical and tribological properties, low thermal expansion coefficient and chemical stability at high temperature or high pressure. The application of ceramic materials is useful to solve important problems in mechanical industry, in automatic machines and in packaging industry. For example, ceramic materials are usually the best choice for wear-resistant or self lubricating moving parts, or for components that work in corrosive environments or/and at high temperature, ensuring both structural lightening, high durability, low maintenance costs and high productivity . The innovative advanced ceramics are therefore promising candidates for integration or substitution of traditional materials for transports, for machinery and industrial plants, in order to increase performance, efficiency and sustainability.

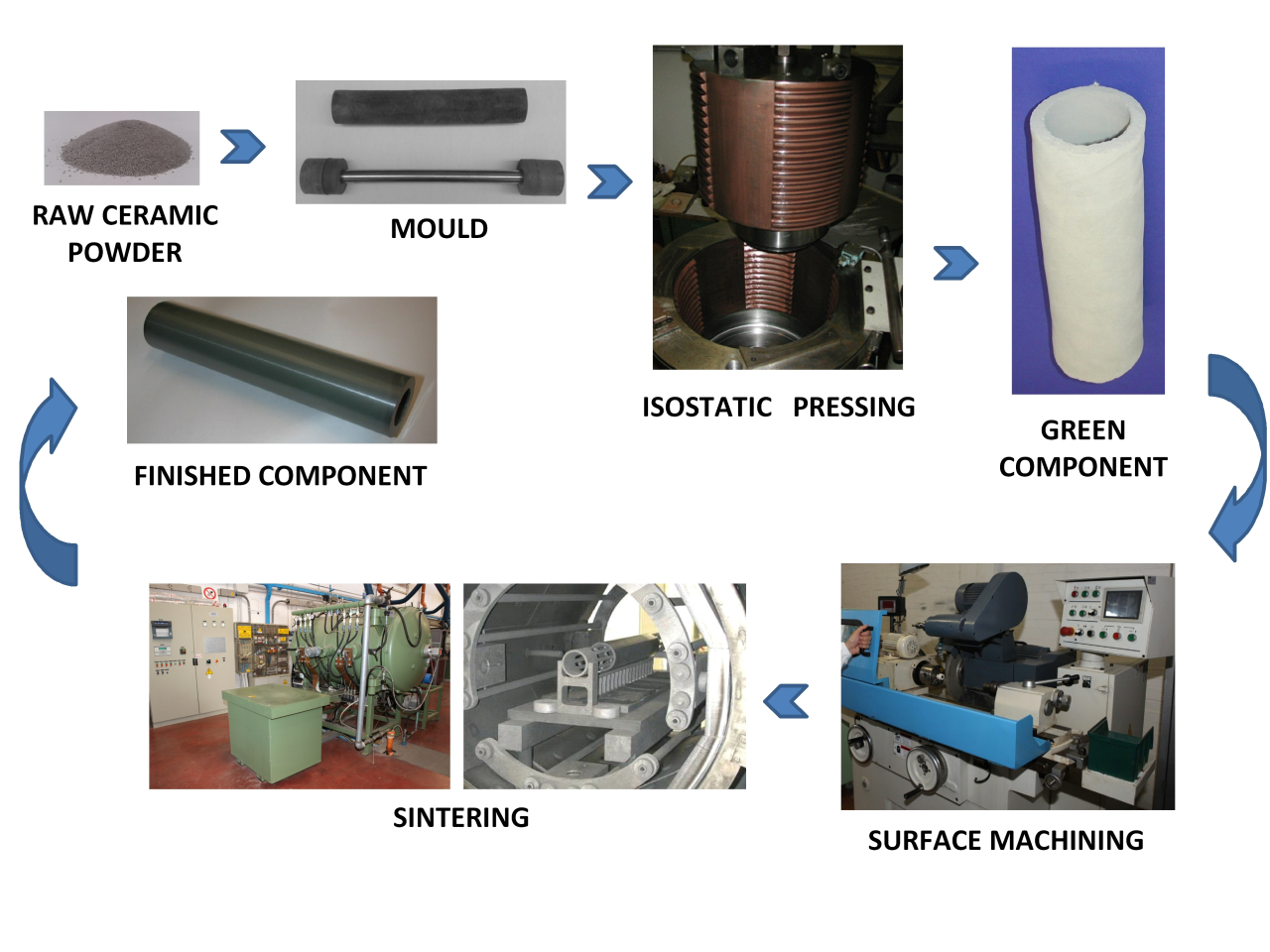

Manufacturing process of ceramic components

Manufacturing process of ceramic components

The growing scientific and industrial interest in advanced ceramic materials is a consequence of their multiple properties, that can not be found in better known materials; the appropriate choice is the first step for a successful application of advanced ceramic materials are interesting for industrial application with two main purposes: - replacement of conventional materials in pre-existing applications, where the introduction of ceramic materials allows productivity increase, the resolution of technical problems and/or economic advantages; - development of completely new products or processes, not achievable with conventional materials.

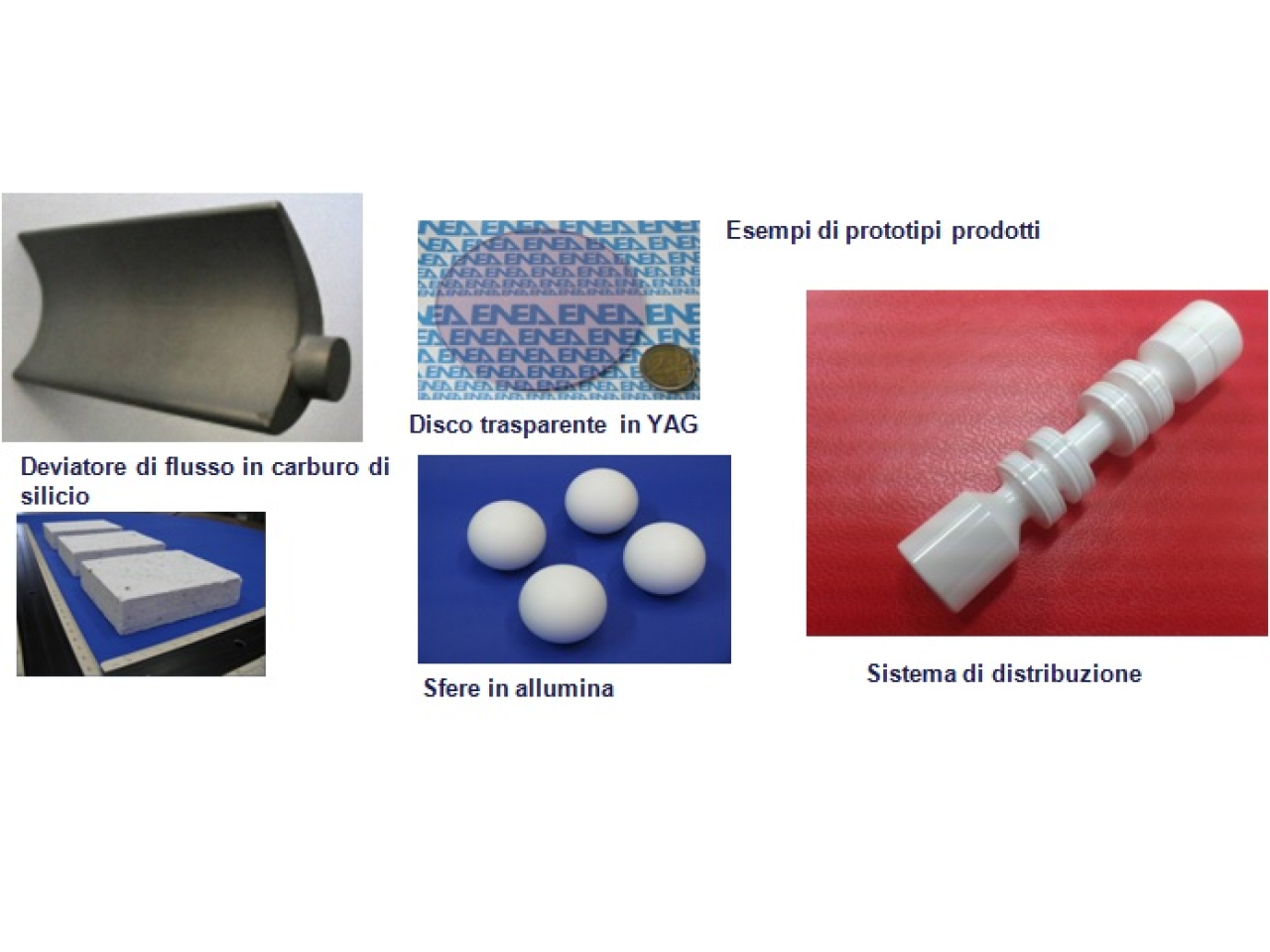

ENEA Faenza develops innovative ceramic materials, components and technology processes up to the manufacturing of prototypes and small series using prototype production methods, upon private or public funding. Examples of application fields of industrial interest are the following: - transport sector: components for braking systems, components for aircraft engines - energy production sector: components for turbine - energy efficiency of industrial processes: components for medium and high temperature heat exchangers, burners for industrial boilers, leachable ceramic cores - machinery sector: seals and dispensers for the packaging industry - antiballistics: plates for bullet-proof jackets.

Example of manufactured prototype

Example of manufactured prototype

CERAMIC PROTOTYPES FOR AERONAUTICAL TURBINES

The realization of stator blades for aircraft turbine engines is a typical case in which ceramic materials are required; ceramic blades allow to increase the working temperatures in order to increase efficiency, reduce costs and the environmental impact of aircraft. This problem is common to several application areas for example in industrial plants or in transport sector. In the specific case, the ceramic material used is silicon carbide (SiC). SiC based materials are the leading candidates to replace the currently used metal alloys, because the mechanical and thermal performance of SiC allow to overcome present limits of operating temperatures, up to several hundreds of degrees. In the specific case of the stator blades, ENEA Faenza has defined each step of the manufacturing process, starting from the component design up to its realization. On the basis of required thermomechanical properties and of expected geometry, the most suitable commercial raw material was chosen and the following steps were optimized: powder pre-treatment (mixing, additives), forming (axial pressing, isostatic pressing or near net shape) and sintering thermal treatments. At the same time, the development of the mechanical and surface finishes processing was also carried out. The prototypes were therefore characterized by bench test in expected working conditions. The prototype allowed to verify the feasibility of the manufacturing process and the component performances in expected working tests. Companies can hence evaluate the benefit of a possible acquisition of technologies. In the specific case, the advantage of the introduction of a ceramic component in a device, is also evaluated by the company for the aspects related to the manufacturing technologies transfer.

Avio spa, Consorzio CETMA

The component has been realized within the project Turbocer "Ceramic Material Development for Wheel Stator of aeronautical turbines". The material and manufacturing technologies have been further developed for other specific applications. Patent IT 0001362972 (2009) "Procedimento per la realizzazione di materiale sinterizzato a base di carburo di silicio e nitruro di alluminio" G. Magnani, L. Beaulardi.

Prototype series of monolithic SiC statoric blade; Compressive breaking load tests of SiC prototype

Prototype series of monolithic SiC statoric blade; Compressive breaking load tests of SiC prototype