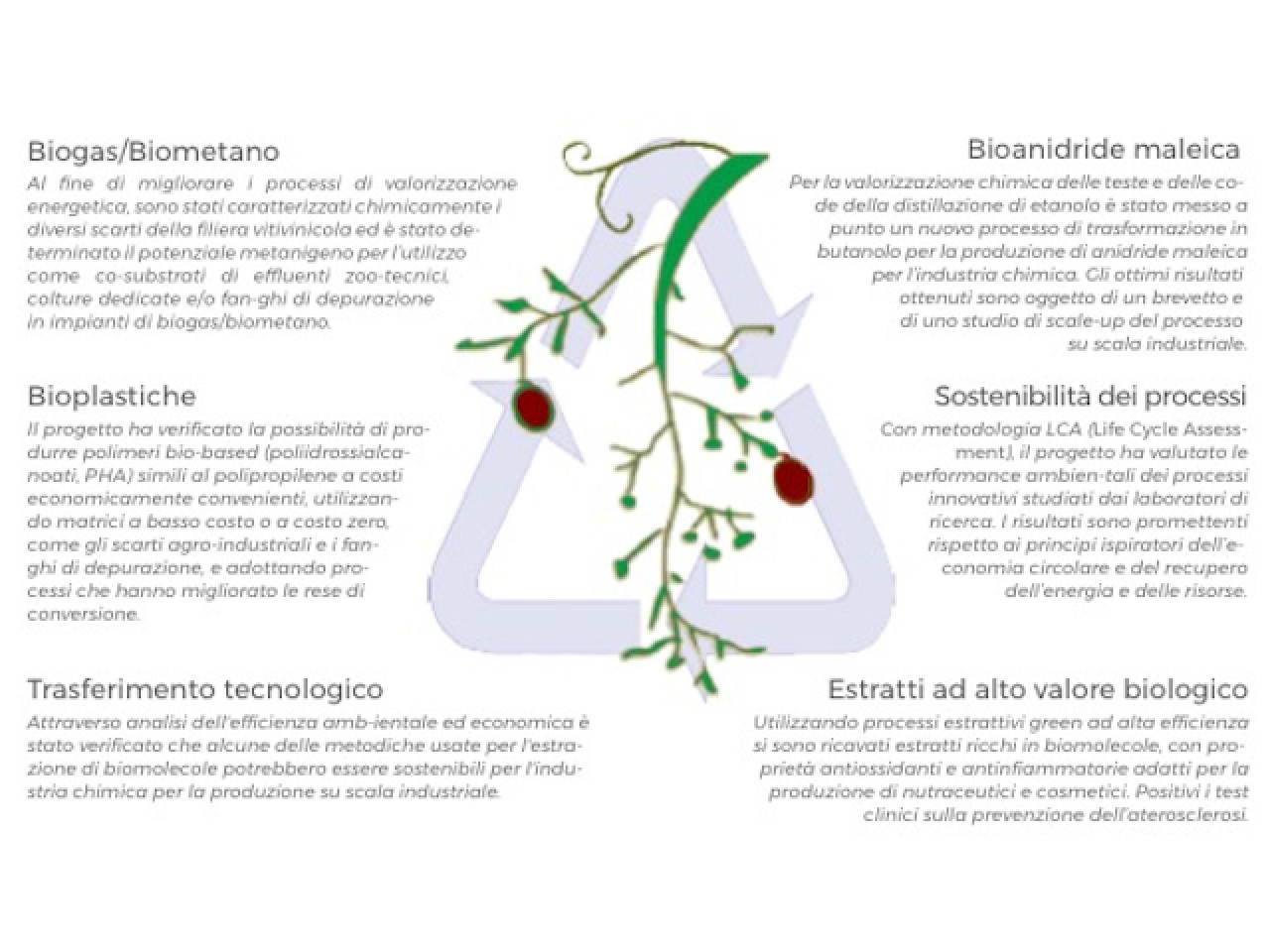

The VALSOVIT project has been proposed as a tool of technological innovation for the valorization of the waste of the wine production chain for the production of high added-value substances using sustainable technologies. The main results obtained in the field of chemical and energetic valorization concerned the production of polyhydroxyalkanoates, butanol as an intermediate for the synthesis of maleic anhydride, of biogas and the related studies of economic sustainability of the processes. Specific results of the valorization in the health field have been the optimization of green extraction processes for the recovery of active biomolecules and the identification, through appropriate in vitro and in vivo biological tests, of extracts to be used as ingredients for functional products

The grape waste is transformed into high added-value products through sustainable chemical and biotechnological processes

The grape waste is transformed into high added-value products through sustainable chemical and biotechnological processes

The second-generation valorization result in an important impact on the chemical and health industry by promoting, with an operating approach inspired to an industrial symbiosis model, a sustainable technological development of the supply chain. In the context of chemical valorization, by-products are used for the production of platform chemicals and bio-polymers. Compared to the healthy fallout, the state of the art draws a substantially unexplored regional context, but strongly leaning towards the search for new natural sources for the exploitation of active biomolecules

- Use of a sustainable, modular and expendable processes also in other supply chain contexts, for the extraction of active biomolecules usable in diversified industrial contexts - use of extracts for the formulation of supplements and functional foods - development of plants for the production of butanol from heads and tails of distillation of ethanol - use of bioplastics from agri-food waste for packaging, mulching sheeting in agriculture - the application of the LCA methodology to different scenarios of biomass exploitation

The main outputs of the Valsovit project

The main outputs of the Valsovit project

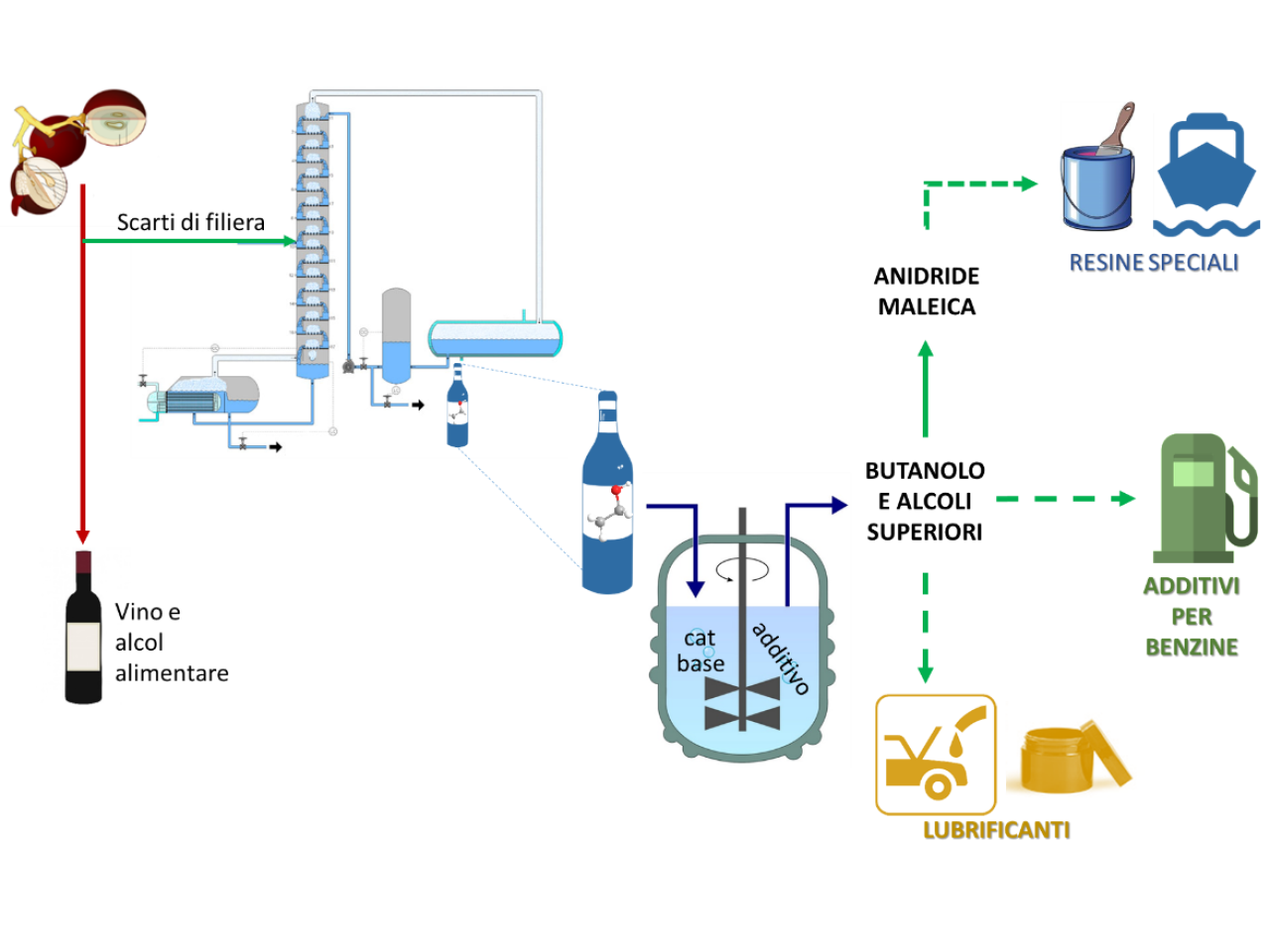

Improved process for the transformation of bio-ethanol from waste of wine industry in butanol as an intermediate for the production of maleic anhydride and higher aliphatic alcohols exploitable as fuels or lubricants

The process, once developed, has been transferred to a real matrix, that is ethanol from the wine industry containing impurities provided by the CAVIRO company, demonstrating that, not only does it maintain the same conversions and selectivity in the presence of organic by-products contained in the feeding, but it also resists in the presence of substantial quantities of water up to the value of azeotrope (5% of water). This type of approach, which represents a considerable advantage from the point of view of the waste distillation economy, is also innovative as the first to evaluate the use of a real matrix. In collaboration with the LEAP-Polimi, a preliminary batch process scheme has been defined with three sections: reaction unit, separation section and distillation unit. The products of interest and the catalyst are separated from the by-product (sodium acetate) by washing with ethanol. Suitable heating units are then provided to induce evaporation of products, washing and not converted ethanol with consequent recovery of the catalyst. The gaseous stream thus generated can be directly conveyed into a dedicated distillation column to allow fractionation of the components. Finally, the collaboration with another project unit provided a LCA evaluation of the process.

Terra&AcquaTech; C.R.P.A.;LEAP-Polimi; CIRI-EA; Caviro Distillerie s.r.l.; SADAM; AMBROSIALAB ; CBC-EUROPE; Dipartimento CHIMIND

The product has been enhanced through the filing of a patent application for industrial invention: number 102018000004226

Transformation of bio-ethanol from waste of the wine industry in butanol: intermediate for the production of maleic anhydride and higher alcohols that can be valorized as fuels or lubricants

Transformation of bio-ethanol from waste of the wine industry in butanol: intermediate for the production of maleic anhydride and higher alcohols that can be valorized as fuels or lubricants