Additive manufacturing applied to tubular reluctance electric machines

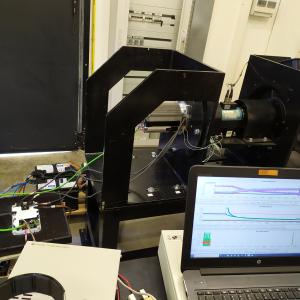

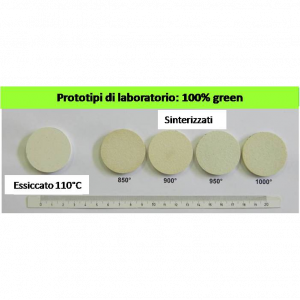

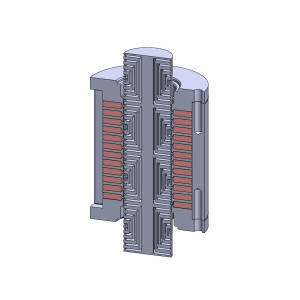

This activity illustrates the design of a tubular synchronous reluctance linear motor, which mover is made by metal additive manufacturing. Tubular motors are used in industry for several advantages: zero radial force, direct linear motion (more...