In order to optimise material and/or energy recovery processes, it is required to have quantitative data on potential material flows and on their trends over time. For this purpose, a tool such as the Material Flow Analysis (MFA) allows flows to be quantified in order to close anthropic activity cycles. This methodology, jointly with LCA (Life Cycle Analysis) tools also allows environmental impacts to be assessed based on future recycling scenarios.

Laboratory activities at CIRI ENA

Laboratory activities at CIRI ENA

The use of dynamic Mass Flow Analysis (MFA) is an innovative methodological approach to assess the reserves in use of a material, of which there are no examples in Italy. The tool is inspired by the possibility to identify current and future recycling flows of materials, considering the actual potential of delivery to the recovery chain.

The proposed approach provides support in identifying the critical points of a recovery chain or process. Therefore this tool lends itself both to nation or region-wide assessments of management policies and to be used by recycling/recovery firms. The forecasting analysis on the potentials of incoming flows to their plants and the assessment of potential impacts stemming from new processes are strategic for investments or technological improvements.

Diagram of possible LCA (Life Cycle Assessment) applications

Diagram of possible LCA (Life Cycle Assessment) applications

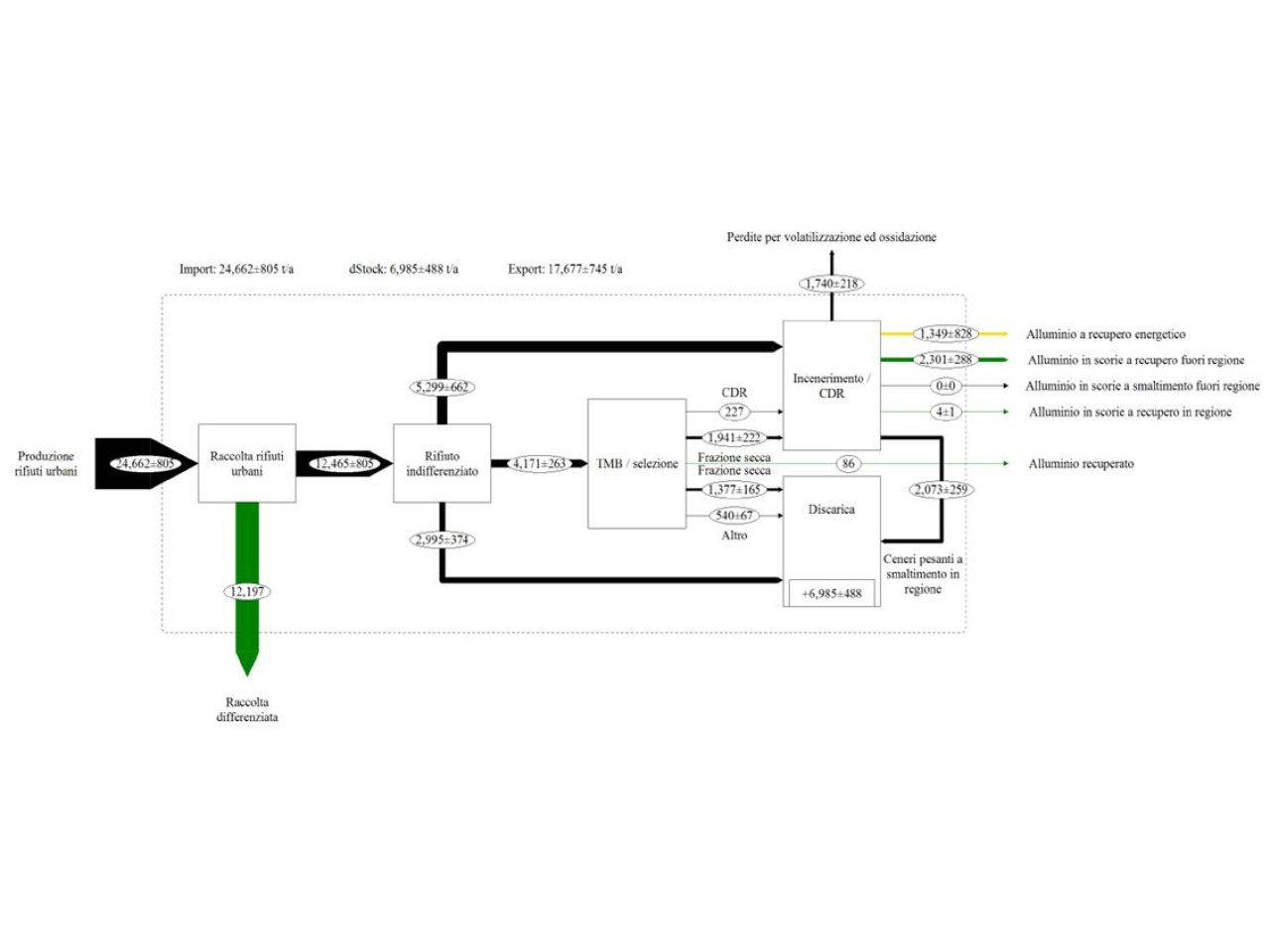

Aluminium recovery from waste processing plants

The study seeks to deepen the detailed analysis and processing of acquired data on the recovery of slag and heavy ashes on a national scale, with regards to the Emilia-Romagna region with a special focus on aluminium recovery/loss. In particular, the study focuses on current and future recovery and/or recycling potentials of aluminium and slag based on quality/quantity features and technologies endorsed or applicable by waste processing plants in Emilia-Romagna. This analysis highlighted the potential of aluminium flows not yet sent for recovery. In particular, the specific flow of metal to be recovered was identified in incinerated slag. A temporal assessment of overall future flows was also carried out.

Firms in the waste processing sector

Ciacci, L., Chen, W., Passarini, F., Eckelman, M., Vassura, I., Morselli, L., Historical evolution of anthropogenic aluminum stocks and flows in Italy. Resources, Conservation and Recycling 2013, 72, 1-8.

Example of MFA Aluminium study in the integrated waste system of the Emilia-Romagna Region

Example of MFA Aluminium study in the integrated waste system of the Emilia-Romagna Region