The hygienic design process takes into account the need to assure foodstuff's safety and suitability, starting from machinery design. This takes place by complying with a series of requirements, known as hygiene criteria in designing, as well as in construction and installation of the equipment. These criteria are obligatory by law pursuant to the Machinery Directive and include: the use of suitable materials and permissible under the specific legislation, easy cleanability, complete drainability and protection from contamination, both external and internal (e.g. lubricants). Today, Parma is the landmark in Italy for hygienic design of food equipment. The laboratory carries out a fundamental role in hygienic design through the partnership with the European Hygienic Engineering and Design Group (EHEDG), the most authoritative international body on these issues worldwide.

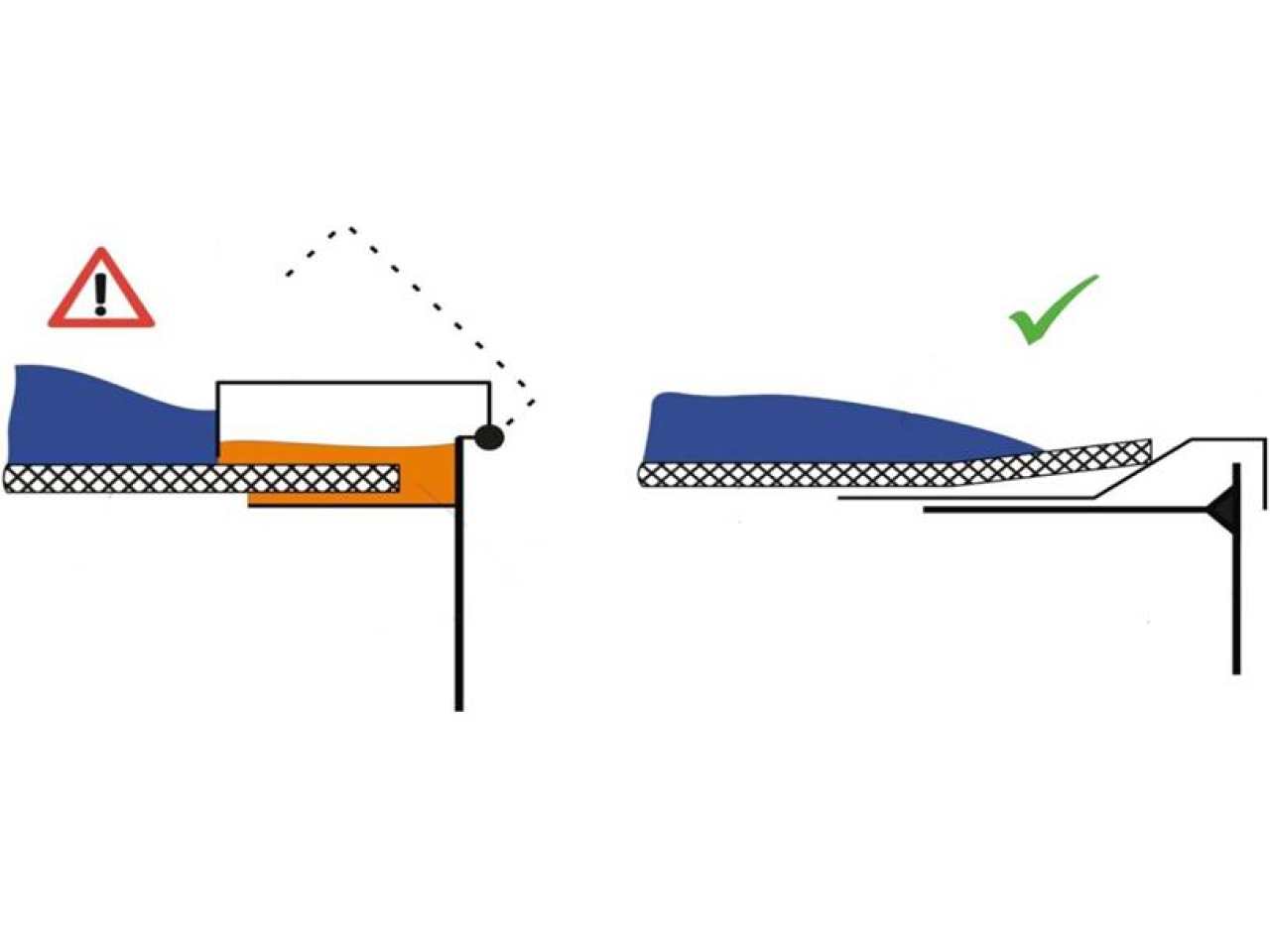

An example of hygienic design excerpted from the EHEDG Doc guideline. 13

An example of hygienic design excerpted from the EHEDG Doc guideline. 13

"Hygienic design" means for users the ability to improve the efficiency of processes, at the same time as assuring more effective process control, hence more straightforward product safety management. "Hygienic design" offers to machinery producers the ability to offer equipment that satisfy even the most demanding customers in terms of safety with significantly lower operating costs than traditional ones.

"Hygienic Design" applies to food equipment in all sectors, as well as to the equipment used in the pharmaceutics and cosmetics industry. Hygienic Design should be applied starting from the early design stages, although actions to improve existing equipment are also possible, according to priorities of intervention based both on risk assessment and on commercial or economic issues. These interventions are normally preceded by assessments of conformity.

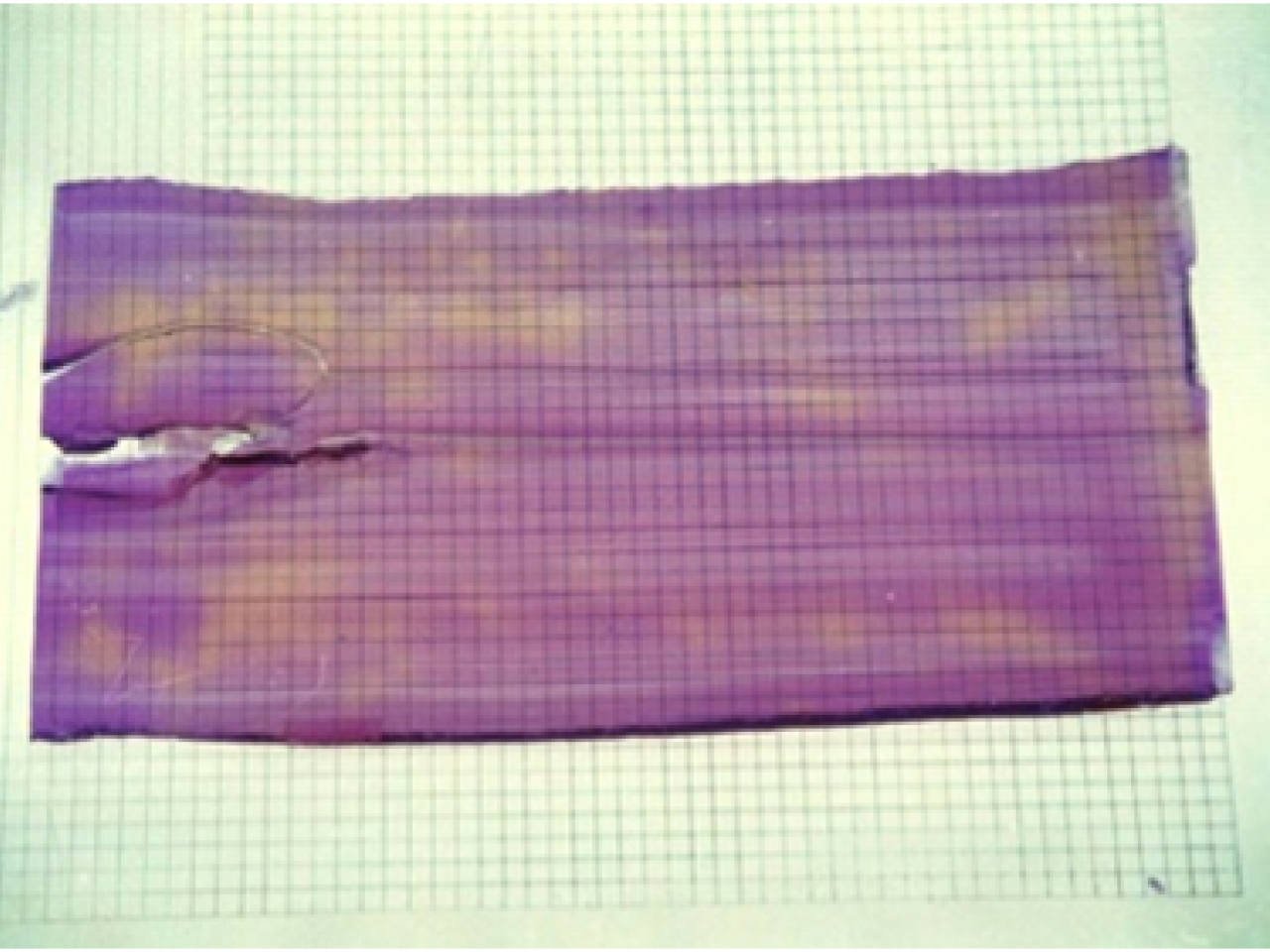

Consequences of non conforming design

Consequences of non conforming design

Design of an innovative aseptic filling machine, in full compliance with hygienic design requirements

The SITEIA.PARMA laboratory has supported the SACMI PACKAGING company in designing an innovative filling machine that is fully compliant with hygienic design requirements. Hygienic design requirements have been considered from the early design stages and have therefore played a determining role in steering towards process, design and constructive choices. Owing to unavoidable requirements of safety, speed, reliability and flexibility, fillers are nowadays extremely complex machines. Only by taking hygiene requirements into account from the very early design stages can a compliant machine be produced at acceptable costs. Hygienic design criteria have been applied to the machine as a whole, in the aseptic chamber, support structures and closed equipment it encases. Individual elements such as surfaces, components, piping were designed complying with specific hygienic design criteria. Materials as well as trade components to be inserted in the machine were selected according to the same criteria. The machine thus designed is optimised from the hygienic point of view, hence safer for the product and less costly in operation for the user, as it is more easily cleanable, sanitisable and of easy maintenance thanks to enhanced accessibility

SACMI PACKAGING

The trend we have observed in recent years in the food sector is to assure high production safety and quality levels. This leads to enhanced awareness when purchasing machines that assure optimal hygiene conditions. In order to best address customers' requirements, Sacmi Packaging has set cleanability and sanitisability as priorities in the mechanical design of its machines.

Outcome of a microbiological cleanability test (from EHEDG Doc.2)

Outcome of a microbiological cleanability test (from EHEDG Doc.2)