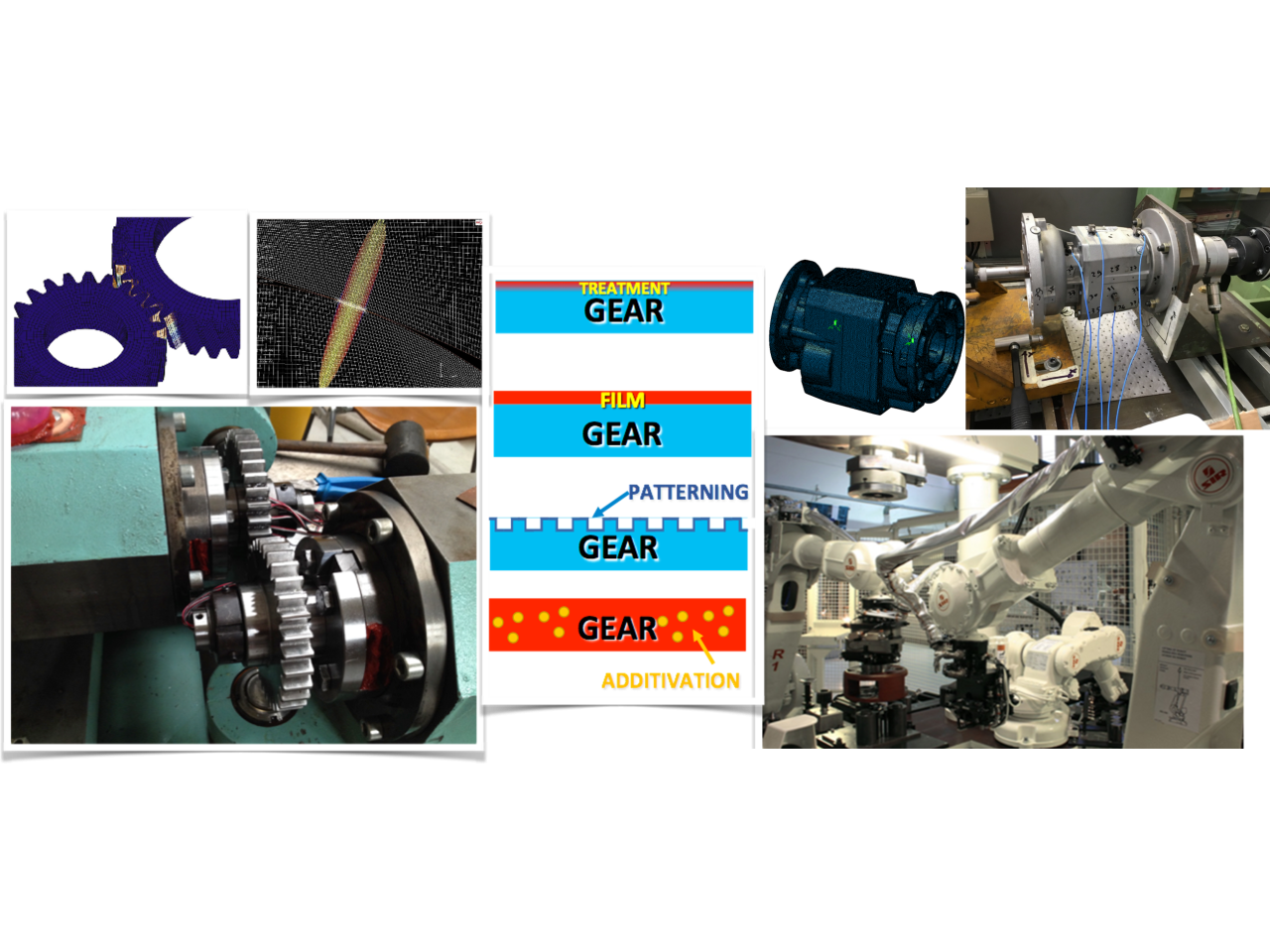

MetAGEAR was born from the initiative of the InterMech regional laboratories MO.RE. and MechLav in order to develop innovative tools for the design and manufacturing of gears and transmission to be made available for the industrial base. MetAGEAR is an integrated software platform that allows to design, simulate and optimize gears and transmissions, taking into account the manufacturing technologies, both in relation to the materials and the surface finishing as well as to the robotized assembly technologies. Modeling techniques for static and dynamic behavior of gears are defined as well, along with tools for optimization, development and application of innovative coatings and surface treatments for gears, advanced CAD design techniques based on parametric archetypes and three-dimensional tolerance chains. Innovative robotized production methods with high precision and reconfigurability are also applied.

Project POR-FESR 2014-2020

Project POR-FESR 2014-2020

The design of transmission occurs via the sector standards, which reflect the manufacturing experience and are integrated with the kwon-how of each companies. This method is not suitable for nowadays production, which is characterized by innovative application and from a large demand of production flexibility. The combination of the optimized design techniques with new material and smart adaptive and integrated design methods supplied by MetAGEAR will guarantee to the companies the possibility to challenge with the most advanced production reality.

Smart design and materials choice allow to obtain an improved transmission efficiency, an increased lifespan and weight reduction. This is possible thanks to sustainable manufacturing and to the usage of high performance materials, coatings and surface treatments. The adoption of innovative high precision robotized manufacturing methods and reconfigurability allows implementing advanced production line and smart adaptive machines.

Topics covered by MetAGEAR project: simulation, research and development of surface coatings for gears and automated assembly lines.

Topics covered by MetAGEAR project: simulation, research and development of surface coatings for gears and automated assembly lines.

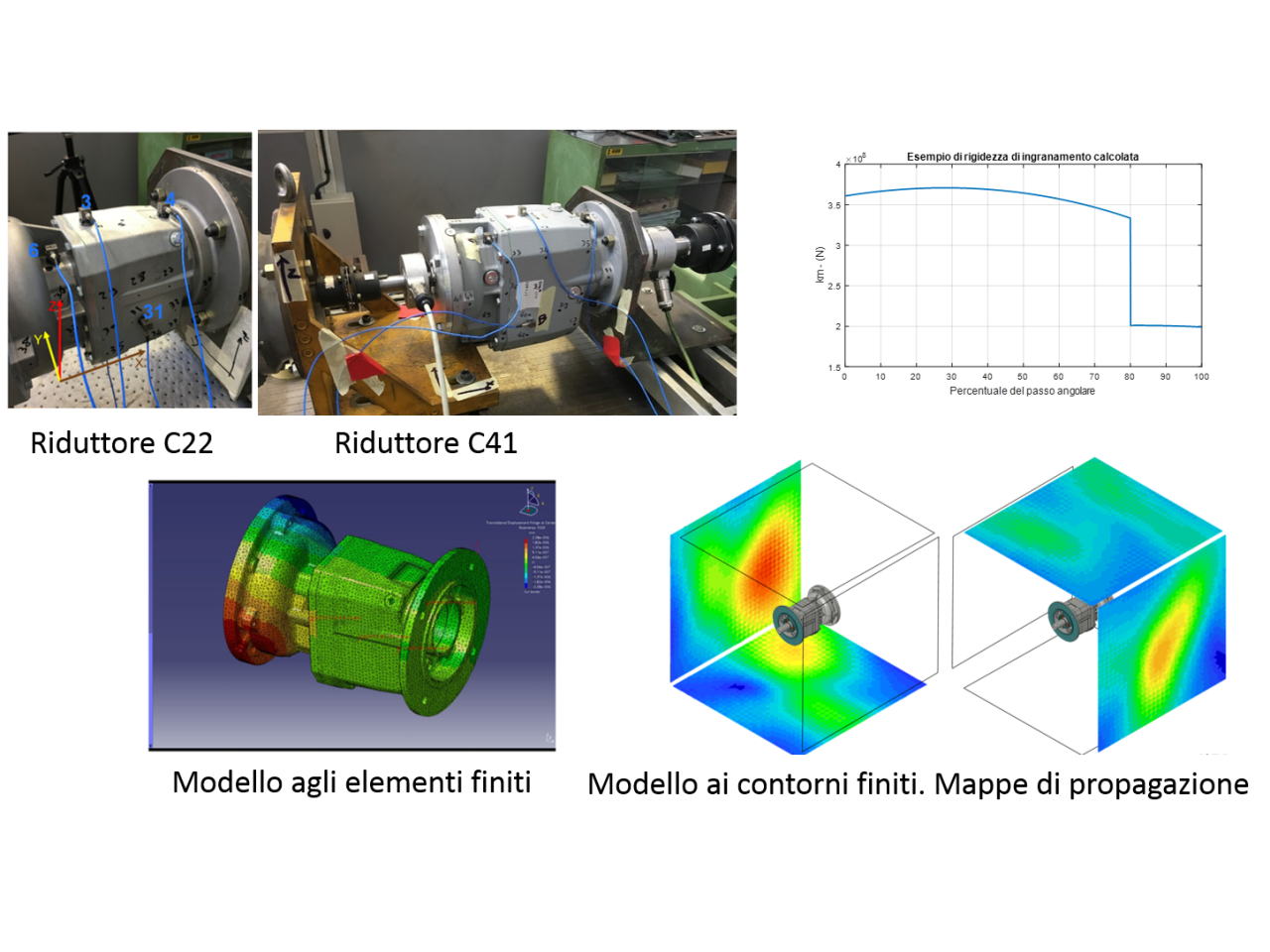

NVH behavior optimization of the Bonfiglioli C22 and C41 gearboxes.

The NVH integrated platform produced by MetAGEAR consists of a lumped parameter model of the bodies in motion (such as gears, shafts, bearings), a finite element model of the gearbox case and a boundary element model to estimate acoustic impact. The NVH platform has been applied to two gearboxes of the Bonfiglioli company.

MechLav – Ferrara Technopole InterMech - MO.RE. Bonfiglioli s.p.a.

The integrated software platform allows to evaluate the influence of the tolerance on the vibration levels, assembly requirements and wear/noise during the meshing by reducing the waiting time. Furthermore, the reduction of research and development times is 30%.

Gearboxes NVH analysis

Gearboxes NVH analysis