INTEGRO is a simple warp horizontal wooden structure with plywood sandwich deck and core in GFRP moulded grating (glass-fibre reinforced plastic). The main structural features are the high degree of rigidity of the deck, especially with regards to stress on the plane, and overall lightness. On the other hand ,the main technical feature is provided by the use of entirely dry procedures and the ability to fit both to new buildings and to renovation projects. The system's performance effectiveness in relation to the overall floor thickness is also assured by the presence of completion packages with materials that both integrate equipment installations and provide optimised solutions to combine thermal-acoustic needs with energy savings. Finally, the system fulfils the reversibility and recyclability requirements of materials and components

Package stratigraphy

Package stratigraphy

The system enables to: - work with dry procedures, in renovation or new construction settings; - ensure high deck rigidity values with low thickness; - ensure rapidity and simplicity of building site operations; - achieve optimised solutions both for environmental comfort and energy consumption requirements, - ensure reversibility and recyclability of materials and components

Activities to replace or recover existing wooden floors with a specific focus on noise reduction or integration of installations. Newly constructed wooden floors with low thickness and high structural rigidity.

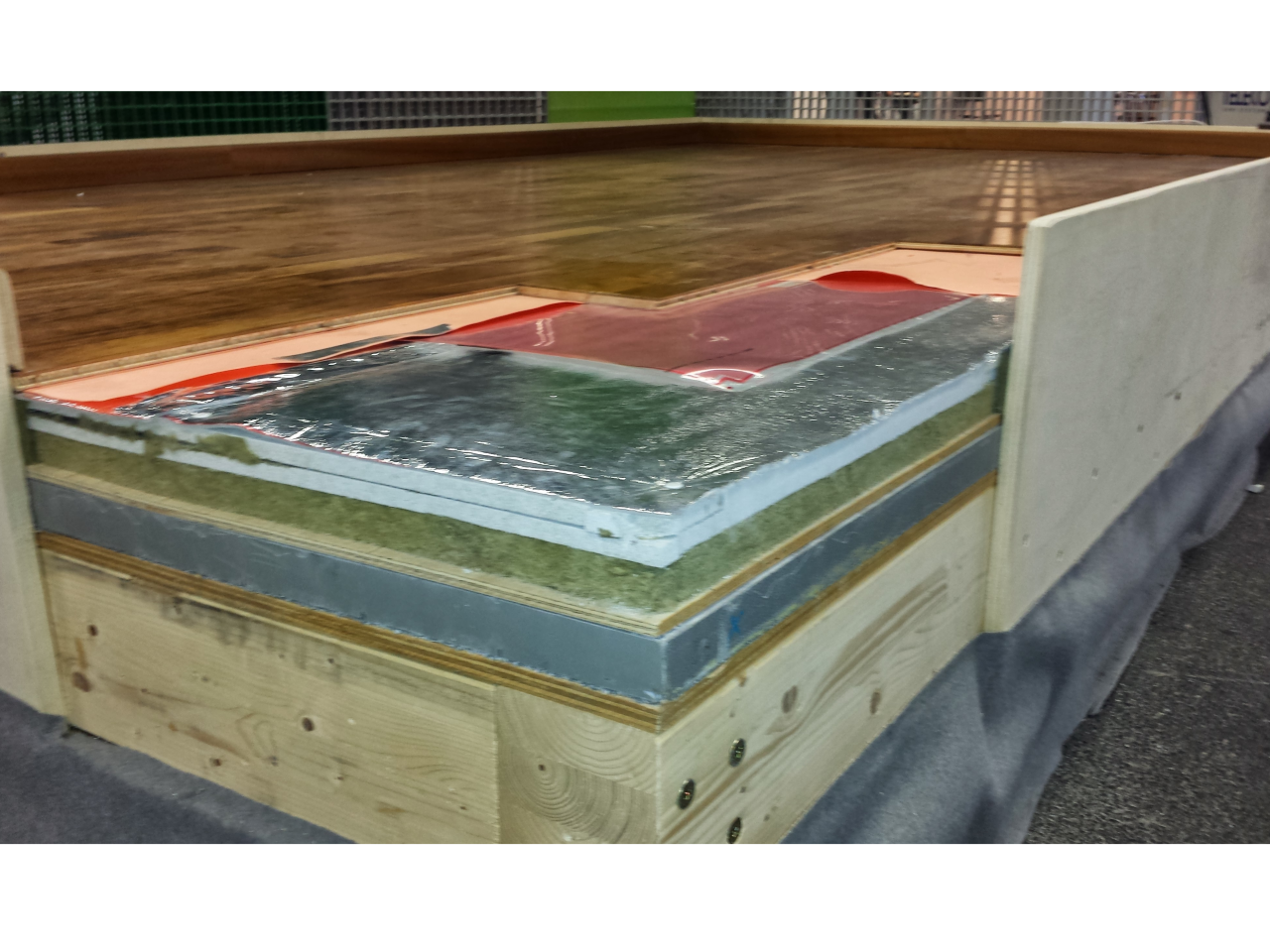

Full-scale prototype

Full-scale prototype

Prototype sized 2.50 m x 4.10 m

The constructive feasibility has been tested by implementing a full-scale prototype with plan dimensions 2.50 m x 4.10 m. The warp structure consists of continuous solid wood edging and three intermediate beams (centre distance 1.30 m) the deck has been fastened onto by means of mechanical through links. The completion packages consist of fibre board sheets and cell filling with marble granules, rock wool insulation, heating film, kraft paper and reflective mat. The construction test confirmed the design assumption, as regards both swiftness of laying operations and simplicity of technical procedures, entirely carried out with dry systems. - Thermal tests: transmittance 0.5 W/sqm K; - load tests: load bearing capacity > 400 g/m2; - analysis with thermal imaging camera: very low thermal inertia, full performance after 1hr, no dispersion at the edges.

MM s.r.l.; Fermacell s.r.l; ATH Energia s.r.l; Rockwool; Schiavina s.r.l.

The prototype was exhibited at SAIE 2013 in a devoted to research centres area at the CIRI - Building and constructions booth. The showcase generated great interest among visitors.

Test model in scale

Test model in scale