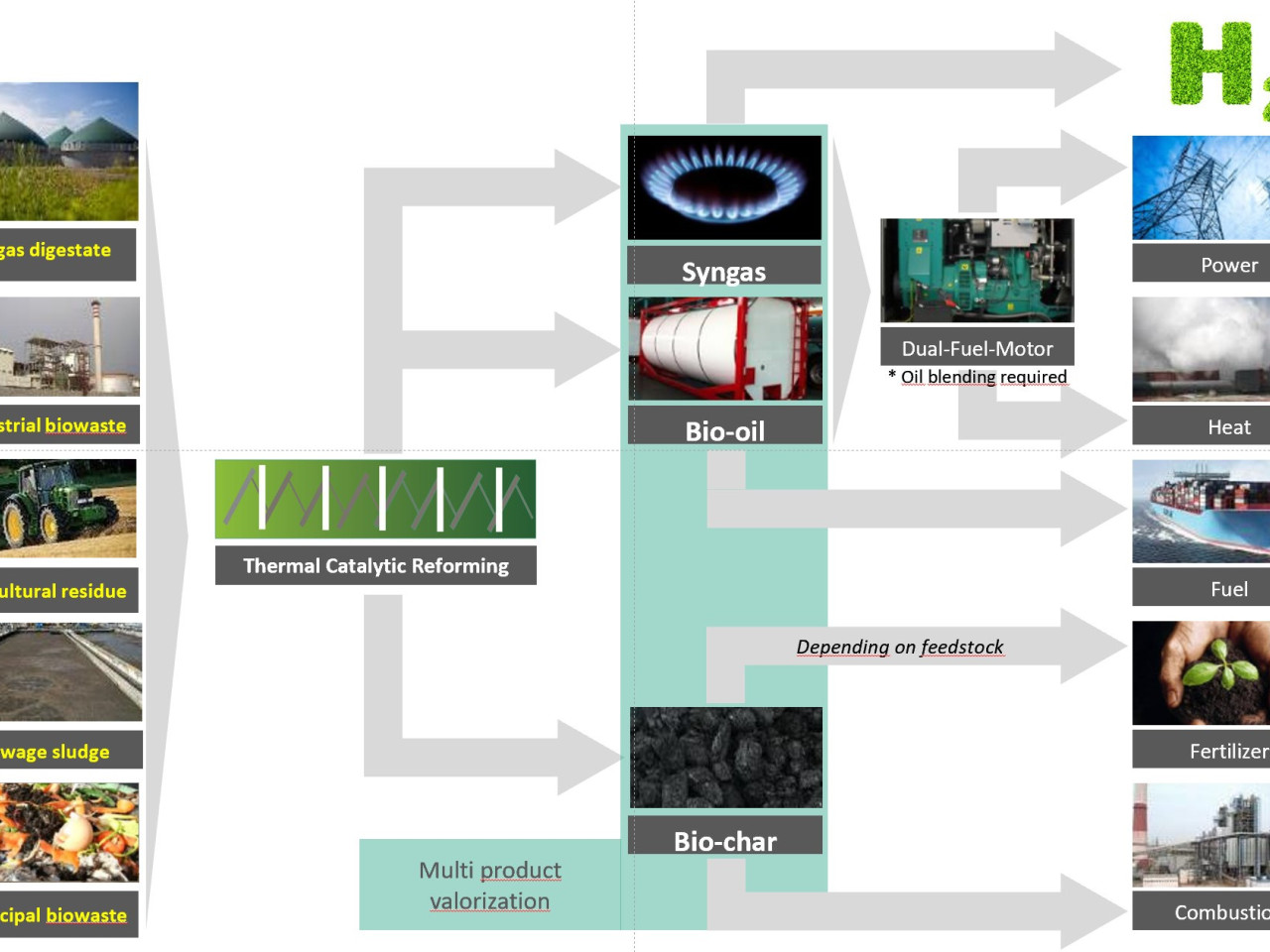

The thermo-catalytic reforming technology TCR® enables added value products such as syngas, green hydrogen, bio-oil and biochar from residual biomass from industries operating in the food, agro, forestry and processing sectors. Such products can be treated for energy production and /or building blocks for chemistry. Sewage sludge, digestate, organic waste can be treated among the several residual biomass types as well as lignocellulosic residues from agricultural crops and animal manure. TCR technology was adopted in collaboration with Fraunhofer UMSICHT Su-Ro.

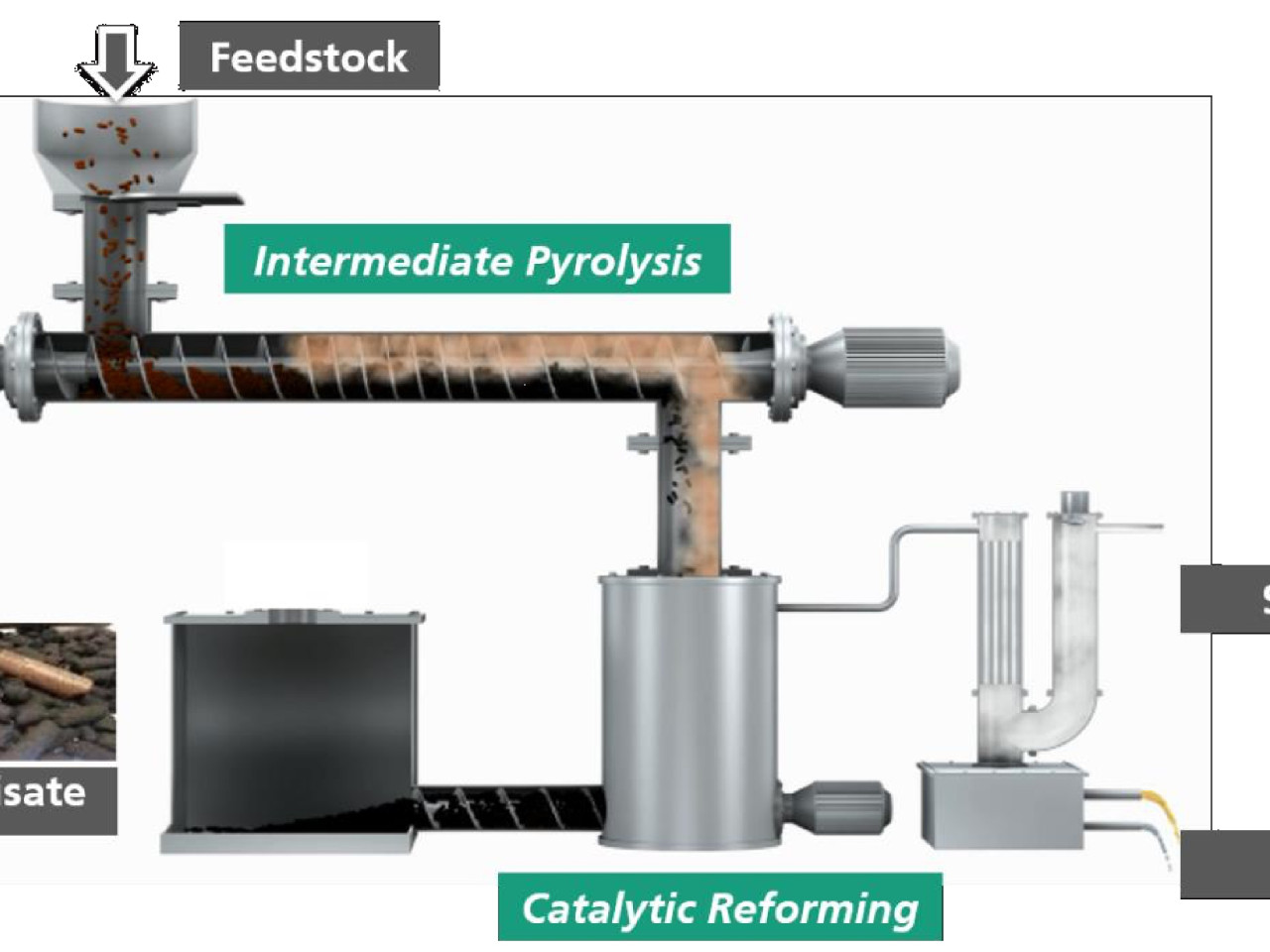

Thermo-catalytic reforming layout

Thermo-catalytic reforming layout

The most innovative feature is the ability of the system to process several types of biomass and the high quality of the products compared to traditional pyrolysis plants.

Energy production is the simplest application for the products. However, biochar can be used as soil improver for agriculture and the other products can be further transformed and purified into green hydrogen and building blocks for the chemical industry.

Flexibility of input feedstock and products obtained

Flexibility of input feedstock and products obtained

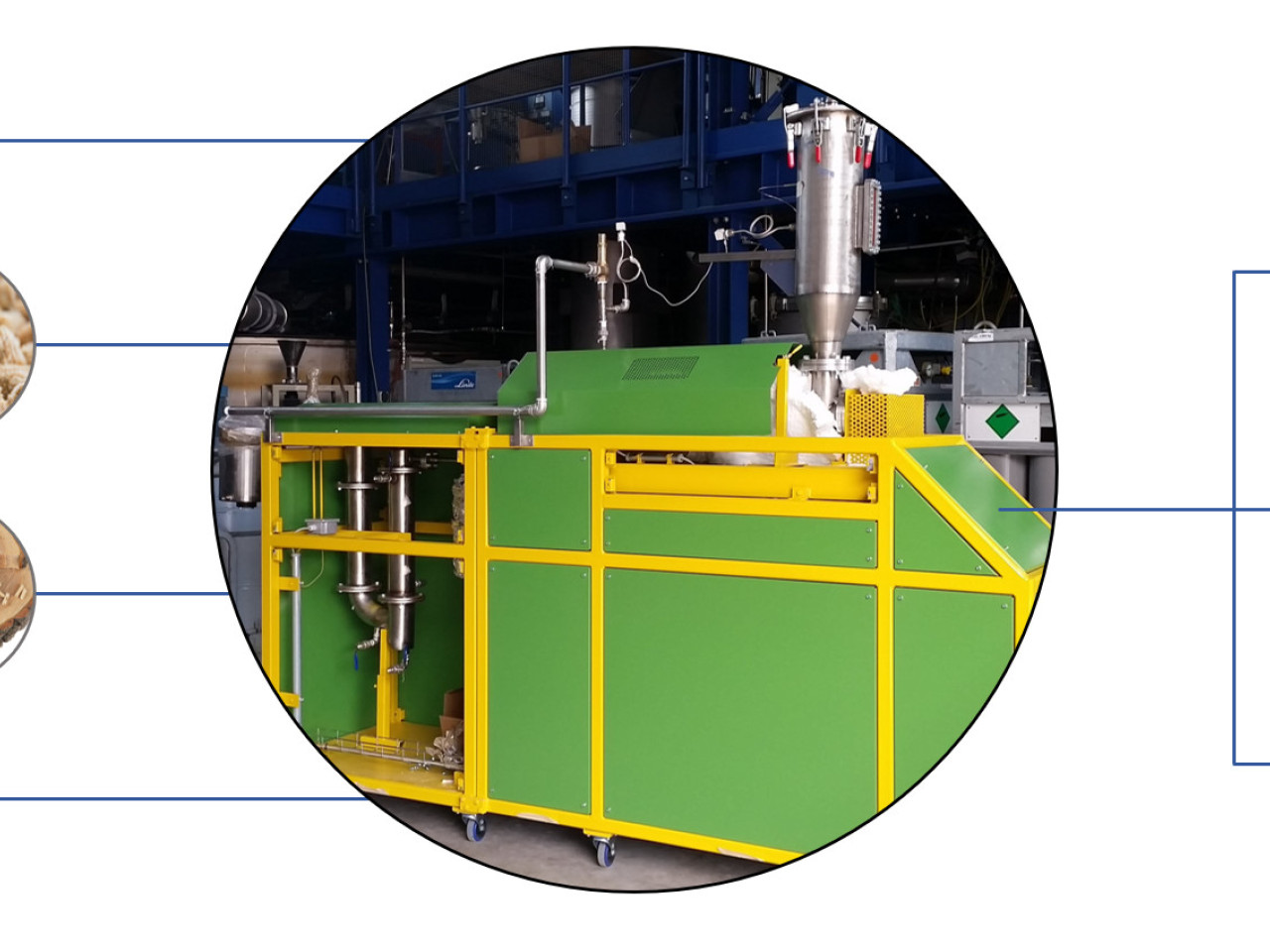

TERMOREF Zerowaste project

Within the TERMOREF Zerowaste project https://site.unibo.it/termoref/it (funded by EmiliaRomagna ERDF 2014-2020) four biomass types were treated using thermo-catalytic reforming: wood pellet, corn cobs, chicken manure, digestate from biogas plants. The specific objective is to verify the suitability and yield by changing the operating conditions. Products were further characterized for the production of biochar, green hydrogen, biomethane and fuel oil as well as chemistry building blocks.

CIDEA, Università di Parma, CNR-ISTEC, CRPA-Lab, Iridenergy e Sauber Technology Services

To better enhance the value of results from the laboratory, our group also provides: a) detailed information on local availability of biomass types derived from our regional database; b) consult on project and regulatory risks; c) carboon footprint and LCA; d) system/ecosystem analysis; e) environmental management systems.

Applications of thermo-catalytic reforming in the TERMOREF Zerowaste project

Applications of thermo-catalytic reforming in the TERMOREF Zerowaste project