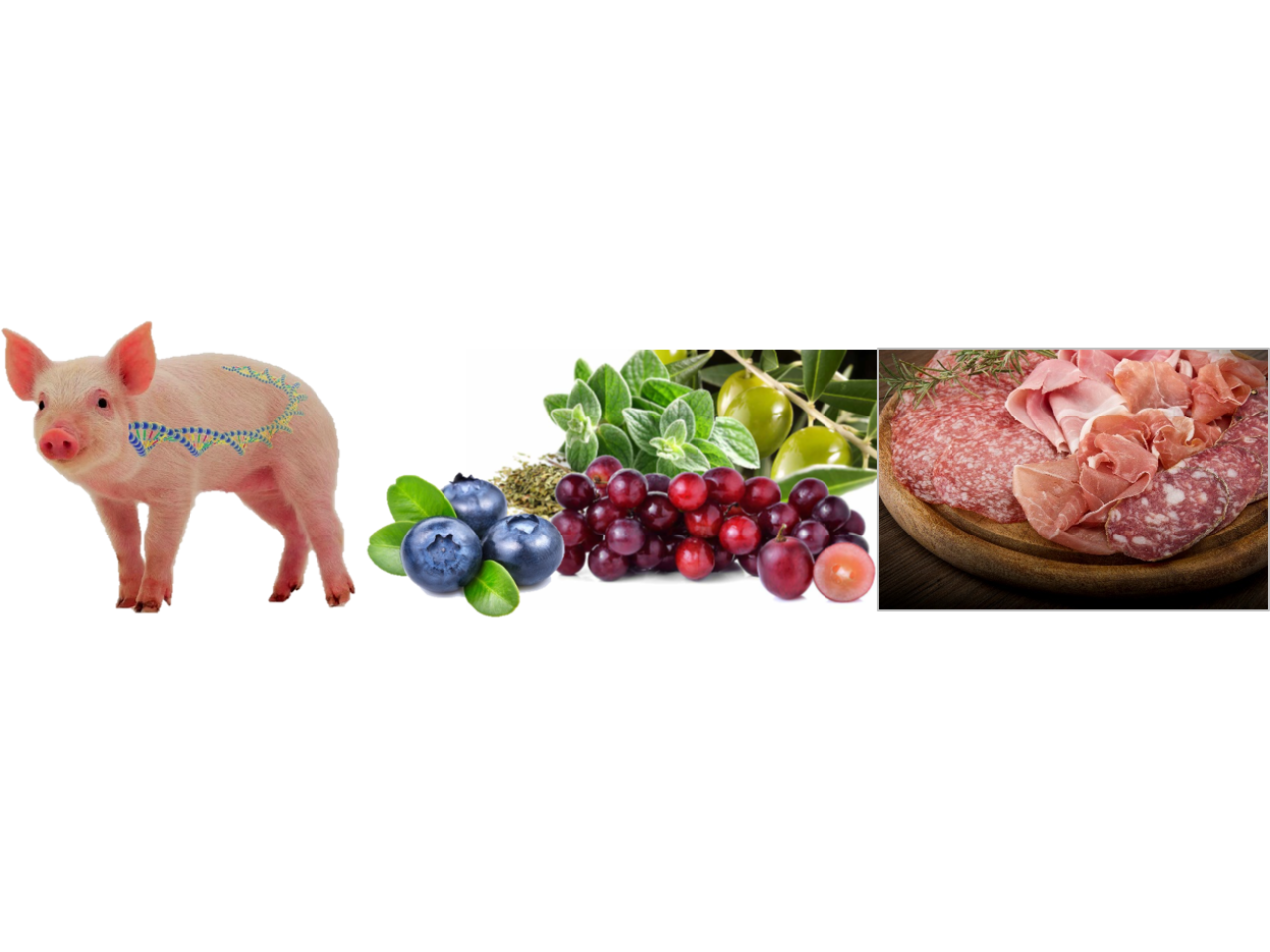

The project has developed innovative technologies for the production of fresh and processed pork products featured of high nutritional quality. Plant extracts, sources of omega-3 fatty acids and natural antioxidants, have been incorporated into pigs’ diet to improve their lipid profile and the expression of some genes involved in lipid metabolism.After the enhancement with omega-3,meat products have been added to phytocomplex, obtained from local fruits and vegetables such as grape and olives, both having an antioxidant and chemoprotective action.Salami and culatte have been produced without using nitrite, focusing on the capacity of natural ingredients,like polyphenols and ascorbic acid, to inhibit the oxidation triggered by iron and lipids. In mortadelle and cooked hams with nitrite the formation of nitrous compounds has been prevented by adding plant extracts.Toxicological tests on intestinal cells have proved a protective effect of plant extracts against pro-inflammatory processes.

Use of nutrigenomic methods to improve the nutritional properties of pork and natural extracts such as antioxidant and chemo-protective ingredients in meat products

Use of nutrigenomic methods to improve the nutritional properties of pork and natural extracts such as antioxidant and chemo-protective ingredients in meat products

Pigs antioxidant enriched feeding from the grape skins, the oregano and the linseeds.Production of pork meats enriched with omega-3 fatty acid stable to the oxidation. New technologies to manufacture meat products enriched with omega-3 fatty acids (possibility to declare the claim “source of omega-3 fatty acids”) and with natural ingredients able to prevent the development of oxidation products. Manufacture of phytochemicals used as ingredients within the meat products to increase the antioxidant capacity and the chemoprotective capacity. Pilot plant development for mortadella sausage cooking.

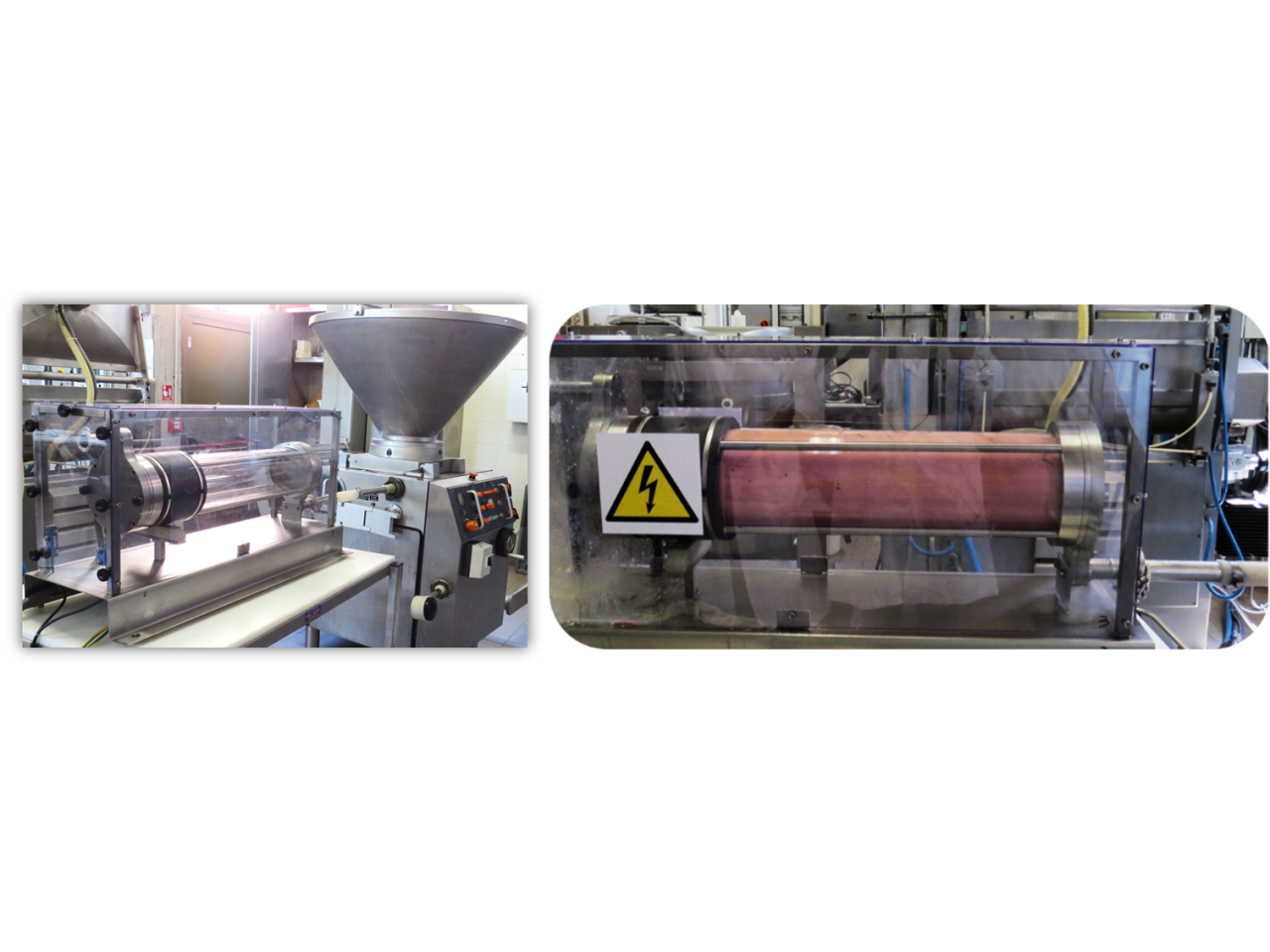

• Nutritional enhancement of pork meat products as a result of a lipid profile enriched in Omega-3 • Production of new plant extracts with antioxidant and chemoprotective properties for meat products • Meat products with higher nutritional properties and clean label through innovative techniques • Ohmic heating of Mortadella • Assessing the nutritional profile of meat products through new analytical markers related to consumers' health

Ohmic heating system for cooking mortadella, connected to the automatic filler machine of the SSICA internal pilot

Ohmic heating system for cooking mortadella, connected to the automatic filler machine of the SSICA internal pilot

a) Preparation of dry fermented sausages “clean label”, meeting the Nutrition Claim “Source of omega-3 fatty acids” b) Nutritional and health biomarkers to better define the innovative dry fermented sausage.

Raw meats were from selected Italian Large White pigs of around 140 kg, fed with supplemented diet rich in vegetable antioxidants (polyphenols from grape and oregano) and linseed. Pork cuts show omega-3 PUFA % about 4 times higher than the standard meat. Medium-grained (5-6 mm) meat batter were prepared with about 18% fat and 2.4% salt, and stuffed into natural casings (ø= 50-60 mm) for salami of about 1 kg. No additives were added, only antioxidant plant extracts (from byproducts of olives, grape, blueberry, green tea and oregano leaves), and low level of sugars (max 0.2%) and starter culture allowing a moderate acidification (pH min> 5,0). A cold drying period (T = 2-3 ° C) was applied for the first period, allowing a slow water activity (aw) reduction. Bioactive components of plant extract, i.e. polyphenol and ascorbic acid (500 mg/kg of meat, each one) are able to counteract both lipid and protein oxidations (TBArs, 4 hydroxy-nonenal, malondialdehyde and carbonyls); the colour of nitrite-free dry fermented sausages is attributed mainly to the formation of Zinc-protoporphyrin (Zn-PP), a natural red pigment. The innovative prototype meets the nutrition claim "source of omega-3 fatty acids", showing also higher antioxidant activity (as Trolox eq.) and lower anti-inflammatory properties (in vitro assay), if comparing to the corresponding standard salami.

SSICA CIRI-AGROALIMENTARE BIOGEST-SITEIA SITEIA.PARMA COMT Ferrarini spa O.P.A.S. Soc. CoopAgr. Villani spa HPP Italia srl

“Green Charcuterie” meat prototypes showed the feasibility of the proposed and tested innovations. During the industrial scale up, the developed formulations and treatments have to be optimize according to the specific company targets. Collaboration of pig-breeder associations and Food Ingredient Producers to better address the production of natural extracts should be considered.

Meat products with omega-3 fatty acids and natural extracts, added as a powder in the mixture or in the saline. Salami and culatte were produced without nitrite.

Meat products with omega-3 fatty acids and natural extracts, added as a powder in the mixture or in the saline. Salami and culatte were produced without nitrite.