Advanced ceramics by 3D extrusion based printing: from the development of ceramic raw materials to the creation of prototypes.

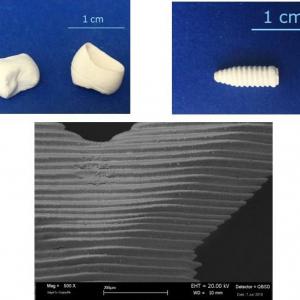

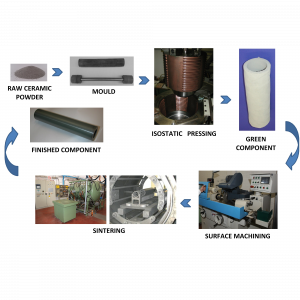

ENEA-TEMAF offers a complete service for the development of advanced ceramic components obtained by 3D printing with the technique based on paste extrusion. The printable ceramic pastes are water-based and characterized by a low organic content (<3%)...