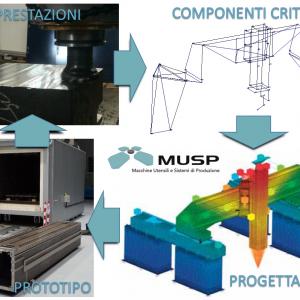

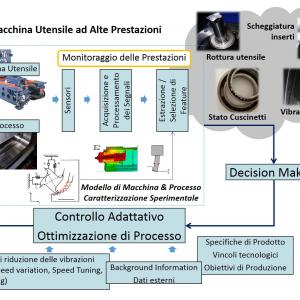

Assembly Processes and Knowledge Formalization

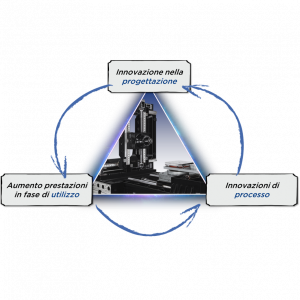

The manufacturing sector today faces a dual challenge: on one hand, the opportunity offered by digital technologies to make processes more efficient; on the other, the growing risk of losing operational expertise gained in the field—especially in...