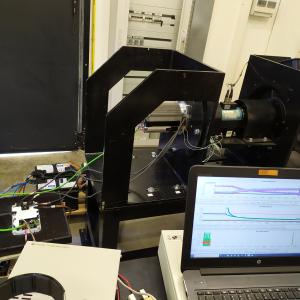

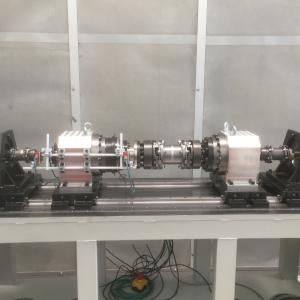

TEST RIG FOR THE CHARACTERIZATION OF SERVOMECHANISMS

Instrumented test rig for fine-tuning and optimization of servomechanisms and/or single functional components, in particular precision reducers, servomotors and compensation joints.

The servomechanisms can be validated on specific load laws with...