Optimisation of heat treatment and coatings for additively manufactured mechanical components

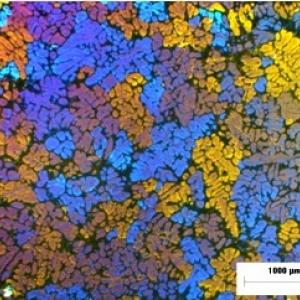

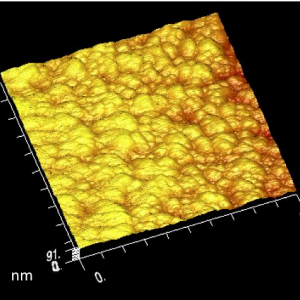

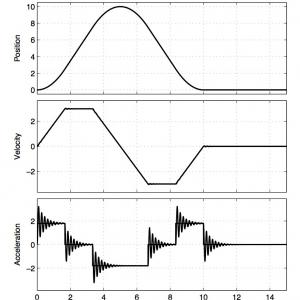

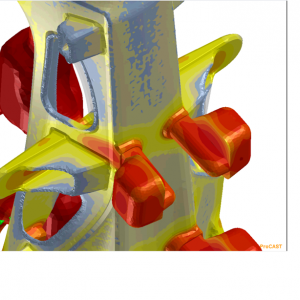

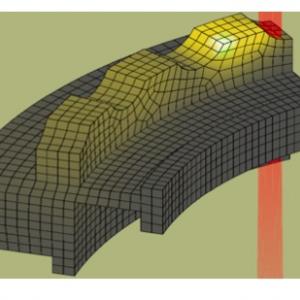

Additive manufacturing (AM) affords design freedom, topological optimization and ability to develop material/component combinations with “site-specific” properties. AM therefore is an effective tool to meet the growing needs of both high...