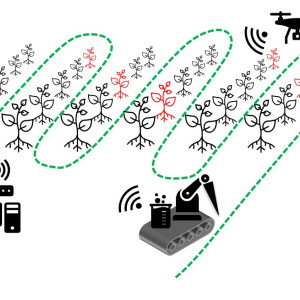

Innovation in Monitoring for Precision Agriculture applications: AGRARIAN project

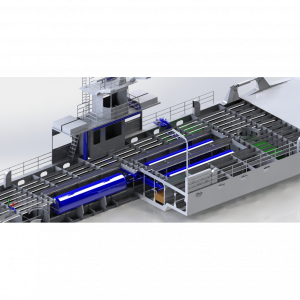

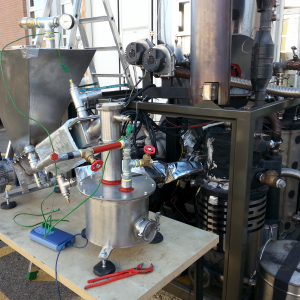

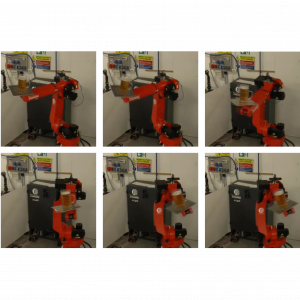

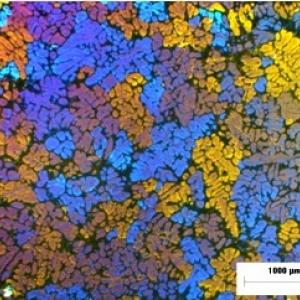

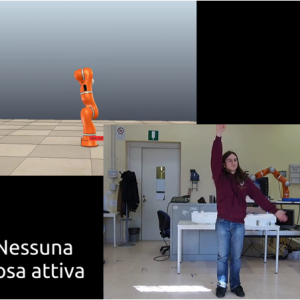

AGRARIAN aims to develop a prototype of an integrated system composed of a mobile ground unit and one or more UAV (Unmanned aerial vehicles) units. These units will coordinate to acquire data relating to soil conditions, environmental parameters, and...