Chemically Bonded Ceramics

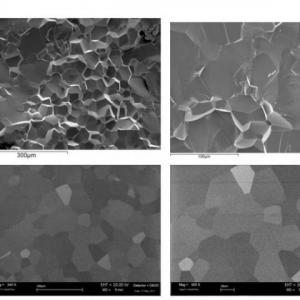

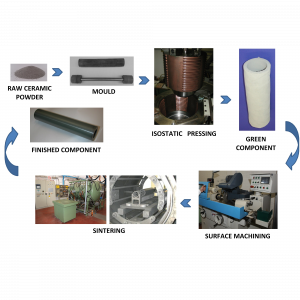

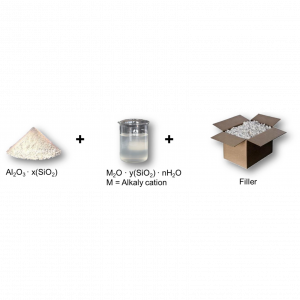

Geopolymers are synthetic inorganic polymers based on aluminosilicates or phosphates and chemically bonded at T <300 ° C. This technology enables the production of materials with properties of certain ceramic materials with the same approach of...